A kind of carboxylated nitrile latex for gloves and preparation method thereof

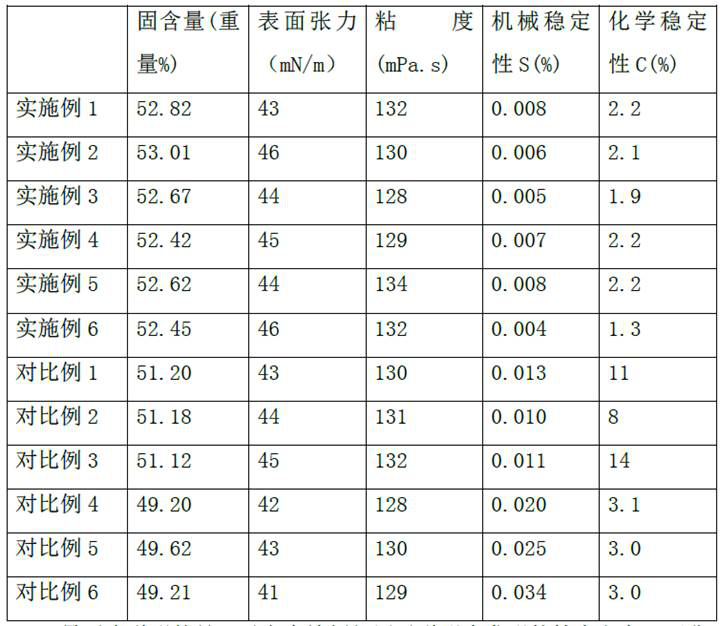

A technology of carboxylated nitrile latex and gloves, which is applied in the field of latex, can solve the problems of insufficient mechanical stability and chemical stability, achieve excellent chemical stability and mechanical stability, improve stability and fluidity, and be easy to control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of carboxylated nitrile latex for gloves, comprising the steps:

[0028] A. In parts by mass, weigh the raw materials, including 80 parts of deionized water, 3 parts of molecular weight regulator, 0.2 part of pH buffer, 6 parts of emulsifier, 40 parts of butadiene, 40 parts of acrylonitrile, functional monomers 10 parts, 5 parts of unsaturated carboxylic acid, 0.3 part of initiator, 0.6 part of auxiliary; the functional monomers are ethylene glycol diacrylate and diallyl maleate with a mass ratio of 1:1:1 esters and propylene acetate;

[0029] The molecular weight regulator is n-dodecyl mercaptan; the pH buffer is potassium hydrogen phthalate and distilled water with a mass ratio of 1.0:9; the emulsifier is dodecyl with a mass ratio of 1:1.2:1 Sodium benzenesulfonate, ethylene oxide lauryl alcohol and propylene glycol monostearate; unsaturated carboxylic acid is methacrylic acid and acrylic acid with a mass ratio of 1:1; initiator is potassium pers...

Embodiment 2

[0035] A preparation method of carboxylated nitrile latex for gloves, comprising the steps:

[0036] A. In parts by mass, weigh the raw materials, including 100 parts of deionized water, 1 part of molecular weight regulator, 0.4 part of pH buffer, 2 parts of emulsifier, 60 parts of butadiene, 15 parts of acrylonitrile, and functional monomers 20 parts, 2 parts of unsaturated carboxylic acid, 1.5 part of initiator, and 0.4 part of auxiliary; the functional monomers are ethylene glycol diacrylate and diallyl maleate with a mass ratio of 1:1.2:0.5 esters and propylene acetate;

[0037] The molecular weight regulator is tertiary dodecyl mercaptan; the pH buffer is potassium hydrogen phthalate and distilled water with a mass ratio of 2:8; the emulsifier is dodecylbenzenesulfonic acid with a mass ratio of 2:0.5:2 Sodium, ethylene oxide lauryl alcohol and propylene glycol monostearate; unsaturated carboxylic acid is methacrylic acid and acrylic acid with a mass ratio of 2:1; initiat...

Embodiment 3

[0043] A preparation method of carboxylated nitrile latex for gloves, comprising the steps:

[0044] A. In parts by mass, weigh the raw materials, including 90 parts of deionized water, 2 parts of molecular weight regulator, 0.3 part of pH buffer, 5 parts of emulsifier, 50 parts of butadiene, 30 parts of acrylonitrile, functional monomers 15 parts, 3 parts of unsaturated carboxylic acid, 1.0 part of initiator, and 0.5 part of auxiliary; the functional monomers are ethylene glycol diacrylate and diallyl maleate with a mass ratio of 1:1.1:0.8 esters and propylene acetate;

[0045] Described molecular weight regulator is n-dodecyl mercaptan and tertiary dodecyl mercaptan with mass ratio of 1:2; pH buffer is potassium hydrogen phthalate and distilled water with mass ratio of 1.5:8.3; emulsifier is mass ratio Sodium dodecylbenzenesulfonate, ethylene oxide lauryl alcohol and propylene glycol monostearate in a ratio of 1.5:1.0:1.5; unsaturated carboxylic acid is methacrylic acid, ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com