Tire glaze with high permeability and durability and preparation method thereof

A high-permeability and durable technology, applied in the direction of coating, can solve the problems of difficult to achieve protective effect, difficult to adhere to active ingredients, poor permeability of tire glaze, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

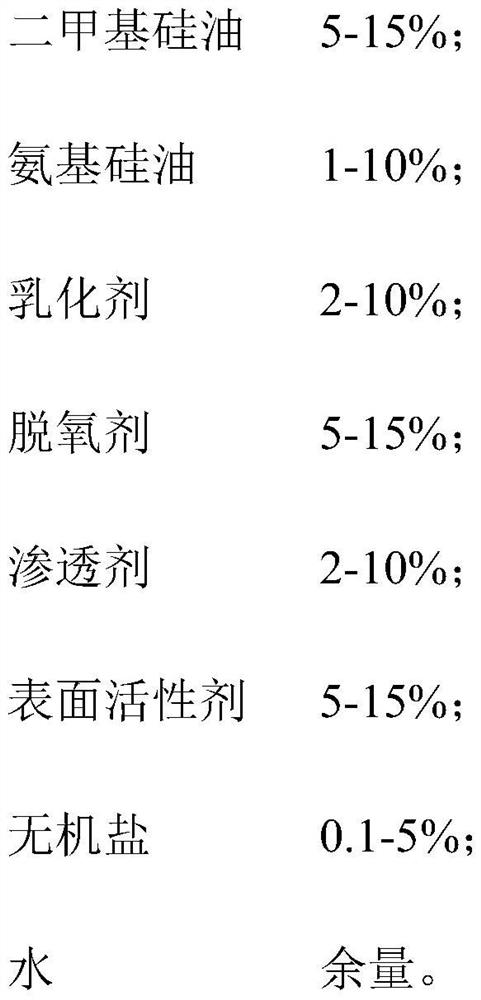

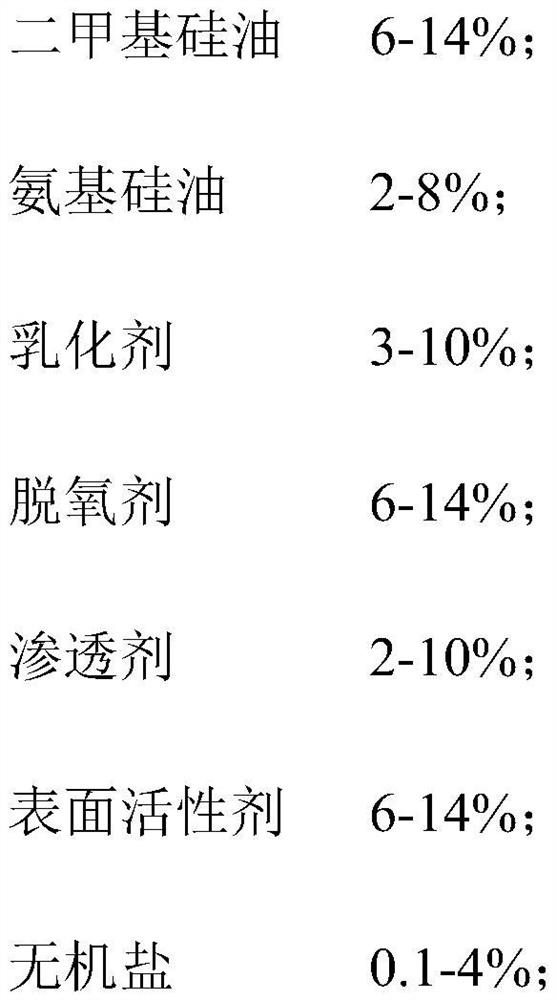

[0041] A highly permeable and durable tire glaze comprising the following components in weight percent:

[0042] Simethicone 8%; amino silicone oil 8%; non-ionic paraffin microemulsifier NMP 5%; No. 120 solvent naphtha 9%; 8% glucoside; 2.5% sodium metasilicate pentahydrate; the balance is water.

[0043] The preparation method of above-mentioned highly permeable and durable tire glaze comprises the following steps:

[0044] S1, take simethicone oil, amino silicone oil and nonionic paraffin microemulsifier NMP and stir in a stirred tank, the stirring speed is 600 rpm, and stir for 15 minutes to obtain the first component;

[0045] S2, adding water, No. 120 solvent oil, penetrant T and alkyl glucoside to the stirring tank in sequence, stirring at a rotation speed of 600 rpm, and stirring for 15 minutes to obtain the second component;

[0046] S3, take sodium metasilicate pentahydrate, add water and stir to dissolve, the stirring speed is 180 rpm, and stir for 6 minutes to obt...

Embodiment 2

[0049] A highly permeable and durable tire glaze comprising the following components in weight percent:

[0050] Simethicone 6%; amino silicone oil 9%; cationic paraffin microemulsifier CMP 4%; No. 70 mineral spirits 7%; penetrant OEP-70 3.5%; fatty acid glyceride 7%; sodium nitrite 3%; the balance for water.

[0051] The preparation method of above-mentioned highly permeable and durable tire glaze comprises the following steps:

[0052] S1, take simethicone oil, amino silicone oil and cationic paraffin microemulsifier CMP and stir in a stirred tank, the stirring speed is 800 rpm, and stir for 8 minutes to obtain the first component;

[0053] S2, adding water, No. 70 solvent oil, penetrant OEP-70 and fatty acid glyceride to the stirring tank in sequence, stirring at a rotating speed of 800 rpm, and stirring for 8 minutes to obtain the second component;

[0054] S3, adding sodium nitrite to water and stirring to dissolve, the stirring speed is 220 rpm, and stirring for 6 minu...

Embodiment 3

[0057] A highly permeable and durable tire glaze comprising the following components in weight percent:

[0058] Dimethyl silicone oil 10%; amino silicone oil 8.5%; anionic paraffin microemulsifier AMP 5.5%; ethyl acetate 8%; penetrant AEP (fatty alcohol polyoxyethylene ether) 3%; sodium dodecylbenzenesulfonate 8.5% %; sodium benzoate 3.5%; the balance is water.

[0059] The preparation method of above-mentioned highly permeable and durable tire glaze comprises the following steps:

[0060] S1, take simethicone oil, amino silicone oil and anionic paraffin microemulsifier AMP and stir in a stirred tank at a stirring speed of 700 rpm, and stir for 10 minutes to obtain the first component;

[0061] S2, adding water, ethyl acetate, penetrant AEP and sodium dodecylbenzenesulfonate in turn to the stirring tank, stirring at a rotating speed of 700 rpm, and stirring for 10 minutes to obtain the second component;

[0062] S3, taking sodium benzoate and adding water and stirring to di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com