Polycrystalline YAG ceramic chemical mechanical polishing solution

A ceramic chemical and mechanical polishing technology, applied in polishing compositions containing abrasives, etc., can solve the problems of undiscovered polishing liquid system, difference in crystalline phase reaction rate, unsuitability of polycrystalline YAG, etc., to achieve high material removal efficiency, The effect of suppressing grain boundary height difference and improving removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Based on the total mass fraction of the polishing liquid as 100%, its components and mass percentages are as follows: 10wt% 20nm silica sol, 1wt% 20nm alumina abrasive grains, 0.5wt% hexadecyltrimethylammonium bromide, 88.5wt %Deionized water.

[0029] The polycrystalline YAG ceramic chemical mechanical polishing liquid described in the present embodiment is prepared by the following steps:

[0030] Rinse the beaker with deionized water and dry it with nitrogen gas;

[0031] Add 88.5wt% deionized water to the cleaned beaker;

[0032] Add 10wt% 20nm silica sol to the above deionized water and stir until uniform;

[0033] Add pH regulator citric acid to adjust the pH of the solution to 7;

[0034] Add 1wt% of 20nm alumina abrasive grains and ultrasonically stir for 10min;

[0035] Add 0.5wt% cetyltrimethylammonium bromide and stir;

[0036] The above mixed liquid was placed in a water bath and sonicated for 30 minutes and stirred until uniformly mixed.

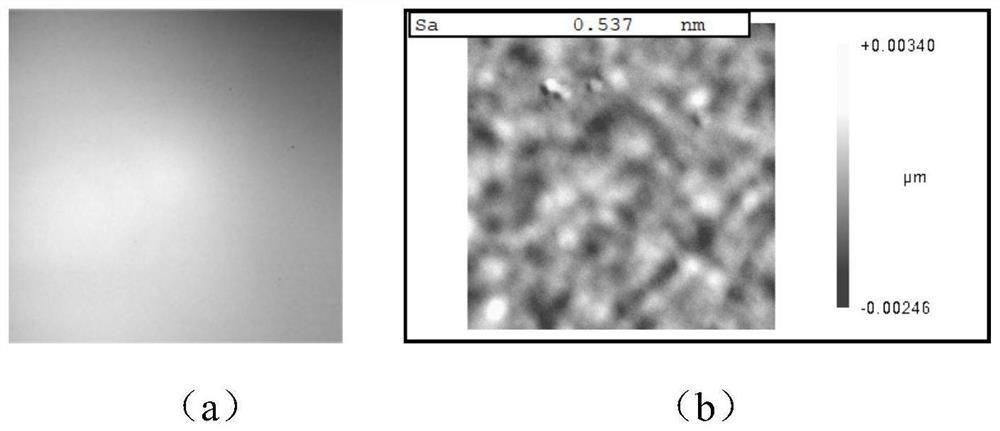

[0037] A po...

Embodiment 2

[0039] Based on the total mass fraction of the polishing liquid as 100%, its components and mass percentages are as follows: 20wt% 20nm silica sol, 3wt% 1μm alumina abrasive grains, 0.3wt% fatty acid polyethylene glycol ester, 76.7wt% deionized water .

[0040] The polycrystalline YAG ceramic chemical mechanical polishing liquid described in the present embodiment is prepared by the following steps:

[0041] Rinse the beaker with deionized water and dry it with nitrogen gas;

[0042] Add 76.7wt% deionized water to the cleaned beaker;

[0043] Add 20wt% 20nm silica sol to the above deionized water and stir until uniform;

[0044] Add pH regulator citric acid to adjust pH to 7;

[0045] Add 3wt% of 1μm alumina abrasive grains and ultrasonically stir for 10min;

[0046] Add 0.3wt% fatty acid polyethylene glycol ester;

[0047] The above mixed liquid was placed in a water bath and sonicated for 30 minutes and stirred until uniformly mixed.

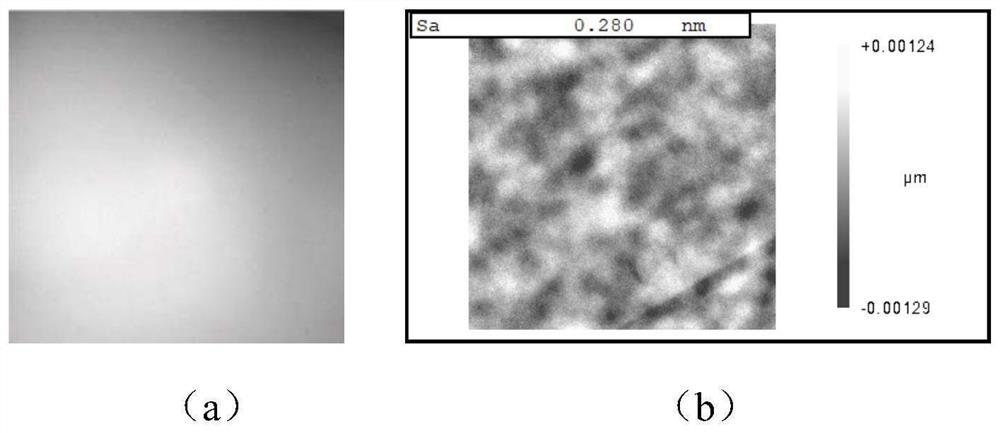

[0048] A polishing experiment was c...

Embodiment 3

[0050] Based on the total mass fraction of the polishing liquid as 100%, its components and mass percentages are as follows: 30wt% 50nm silica sol, 5wt% 1 μm alumina abrasive grains, 0.1wt% cetyltrimethylammonium bromide and stirring, 64.9 wt% deionized water.

[0051] Appropriate amount of pH adjuster, each material is mixed uniformly by ultrasonic in deionized water.

[0052] The polycrystalline YAG ceramic chemical mechanical polishing liquid described in the present embodiment is prepared by the following steps:

[0053] Rinse the beaker with deionized water and dry it with nitrogen gas;

[0054] Add 64.9wt% deionized water to the cleaned beaker;

[0055] Add 30wt% 50nm silica sol to the above deionized water and stir until uniform;

[0056] Add pH regulator citric acid to adjust pH to 7;

[0057] Add 5wt% of 1μm alumina abrasive grains and ultrasonically stir for 10min;

[0058] Add 0.1wt% cetyltrimethylammonium bromide and stir;

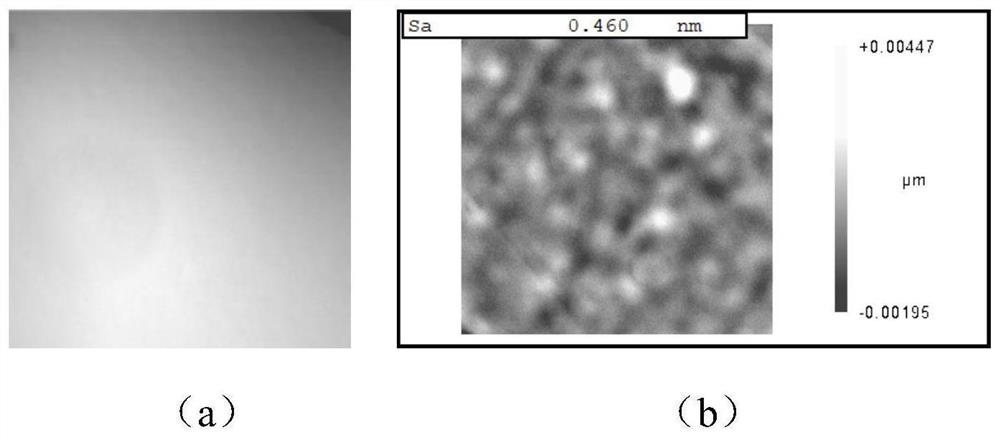

[0059] The above mixed liquid was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com