Natural plant essential oil microemulsion as well as preparation method and application thereof

A natural plant essential oil and microemulsion technology, which is applied in the field of natural plant essential oil microemulsion and its preparation, can solve the problems of high skin sensitization rate and achieve the effect of reducing skin sensitivity, strong uniformity and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

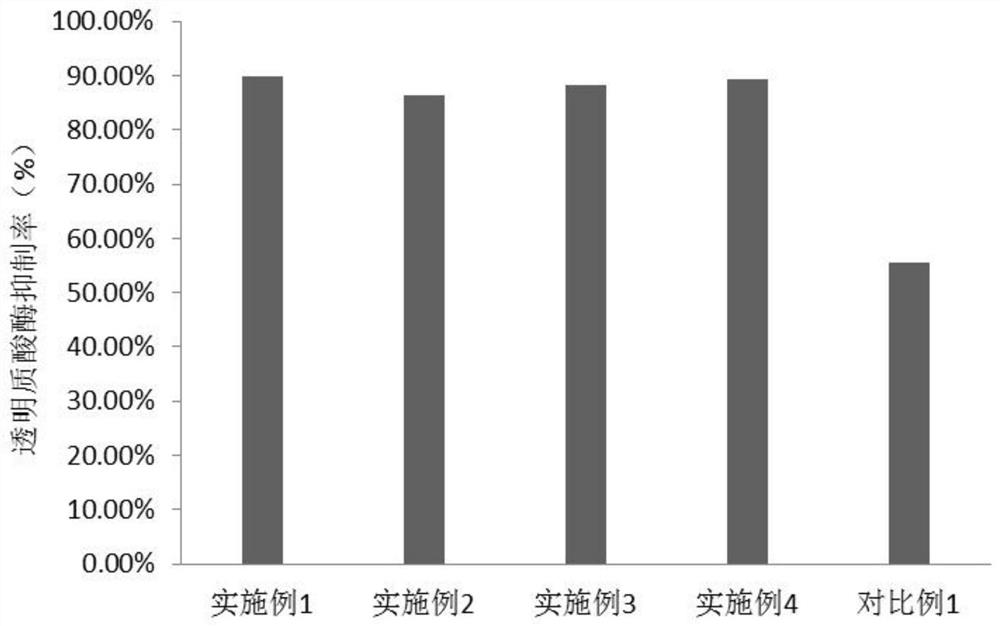

Examples

Embodiment 1

[0046] Embodiment 1: the preparation of natural plant essential oil microemulsion

[0047] In terms of mass percent, 1% lavender essential oil, 5% sapinsin, 0.5% tremella polysaccharide and 93.5% water are uniformly mixed according to the following steps: 1) the natural surfactant is prepared into a mass concentration of 6 % aqueous solution, the natural co-surfactant is mixed with a concentration of 1% aqueous solution, and the aqueous solutions of the two are mixed uniformly; 2) in the mixed solution obtained in step 1), gradually add natural co-surfactant dropwise at a rate of 1mL / min plant essential oil, and stirred at a stirring temperature of 30°C and a stirring speed of 1000r / min for 5min; 3) the mixed solution obtained in step 2) was dripped Gradually drop it into water while stirring at an acceleration of 5mL / min, and homogenize at a temperature of 30°C, a homogenization speed of 6000r / min, and homogenize for 5min; 4) Mix the mixture obtained in step 3) at a temperatu...

Embodiment 2

[0048] Embodiment 2: the preparation of natural plant essential oil microemulsion

[0049] In terms of mass percentage, 1% of lavender essential oil, 2% of chamomile essential oil, 5% of sapinberry saponin, 5% of tea saponin, 2% of tremella polysaccharide, 3% of bletilla striata polysaccharide and 82% of Water, uniformly mixed according to the following steps: 1) Sapindia saponin and tea saponin are mixed and formulated into an aqueous solution with a mass concentration of 10%, and the natural co-surfactant is formulated with a concentration of 6% aqueous solution, and both 2) to the mixed solution obtained in step 1), gradually add natural plant essential oil dropwise at a rate of 4mL / min, and stir for 10min at a stirring temperature of 40°C and a stirring speed of 2000r / min; 3) Add the mixed liquid obtained in step 2) dropwise to water gradually at a stirring temperature of 45°C and a stirring speed of 4000r / min at a rate of 10mL / min while stirring. ℃, the homogenization sp...

Embodiment 3

[0050] Embodiment 3: the preparation of natural plant essential oil microemulsion

[0051] In terms of mass percentage, 3% chamomile essential oil, 2% rose essential oil, 8% tea saponin, 12% saponin, 6% bletilla striata polysaccharide, 4% oat glucan and 65% Water, uniformly mixed according to the following steps: 1) the natural surfactant is mixed with a mass concentration of 40% aqueous solution, the natural co-surfactant is mixed with a concentration of 10% aqueous solution, and the aqueous solution of the two is mixed uniformly; 2 ) to the mixed solution obtained in step 1), gradually add natural plant essential oil dropwise at a rate of 10mL / min, and stir for 30min at a stirring temperature of 50°C and a stirring speed of 4000r / min; 3) the step 2) Under the conditions of stirring temperature of 50°C and stirring speed of 6000r / min, the obtained mixed solution was gradually added dropwise to water while stirring at a dropping rate of 20mL / min. 10000r / min, homogenizing for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com