Flood prevention stone preparation material and preparation method thereof

A technology for preventing stones and stones, which is applied in the field of flood control and stone prevention materials and preparation, can solve the problems of low utilization rate, slow strength growth and low early strength of low-calcium fly ash, so as to save transportation costs and improve utilization rate. , the effect of reducing siltation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

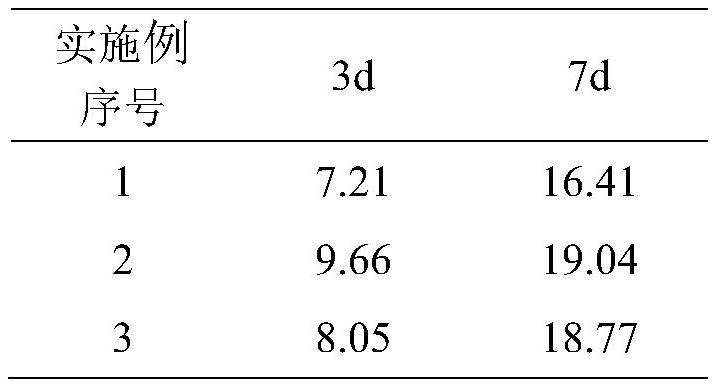

Examples

Embodiment 1

[0018] Flood prevention stone materials include the following raw materials according to weight percentage:

[0019] The low-calcium fly ash is the purchased Class F and Class II fly ash, the dosage is 50%; %; Industrial water glass and sodium hydroxide are the alkali activators that are configured in a mass ratio of 5:3, and the dosage is 8%, wherein: sodium hydroxide is analytically pure, and SiO in water glass 2 The mass content is 29.84%, NaO 2 The mass content is 13.36%, the water glass modulus is 2.3; the tap water is 12%.

Embodiment 2

[0021] Flood prevention stone materials include the following raw materials according to weight percentage:

[0022] The low-calcium fly ash is the purchased Class F and Class II fly ash, the dosage is 40%; the sediment dosage is 18%; the small stone is crushed stone with a particle size of 5-20mm continuous grading, and the dosage is 18% %; Industrial water glass and sodium hydroxide are the alkali activator that the mass ratio is 5:3 configuration, and dosage is 10%, wherein: sodium hydroxide is analytically pure, and SiO in water glass 2 The mass content is 29.84%, NaO 2 The mass content is 13.36%, the water glass modulus is 2.3; the tap water is 14%.

Embodiment 3

[0024] Flood prevention stone materials include the following raw materials according to weight percentage:

[0025] The low-calcium fly ash is the purchased Class F and Class II fly ash with a dosage of 57%; the dosage of sediment is 12%; the small stones are continuously graded crushed stones with a particle size of 5-20mm, and the dosage is 12% %; Industrial water glass and sodium hydroxide are the alkali activator that is configured as 5:3 by mass ratio, and dosage is 9%, wherein: sodium hydroxide is analytically pure, and SiO in water glass 2 The mass content is 29.84%, NaO 2 The mass content is 13.36%, the water glass modulus is 2.3; the tap water is 10%.

[0026] When preparing the flood control stone materials of Examples 1-3, mix the various materials together after weighing according to the proportion of raw materials, dry mix for 5 minutes, add water according to the required amount of water for the wet density, and stir with a pure slurry mixer. Stir at a low spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com