Catalyst for preparing methanol through carbon dioxide hydrogenation and preparation method and application of catalyst

A technology of carbon dioxide and catalyst, applied in the field of chemistry and chemical industry, to achieve the effect of easy preparation, good stability, simple and controllable preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

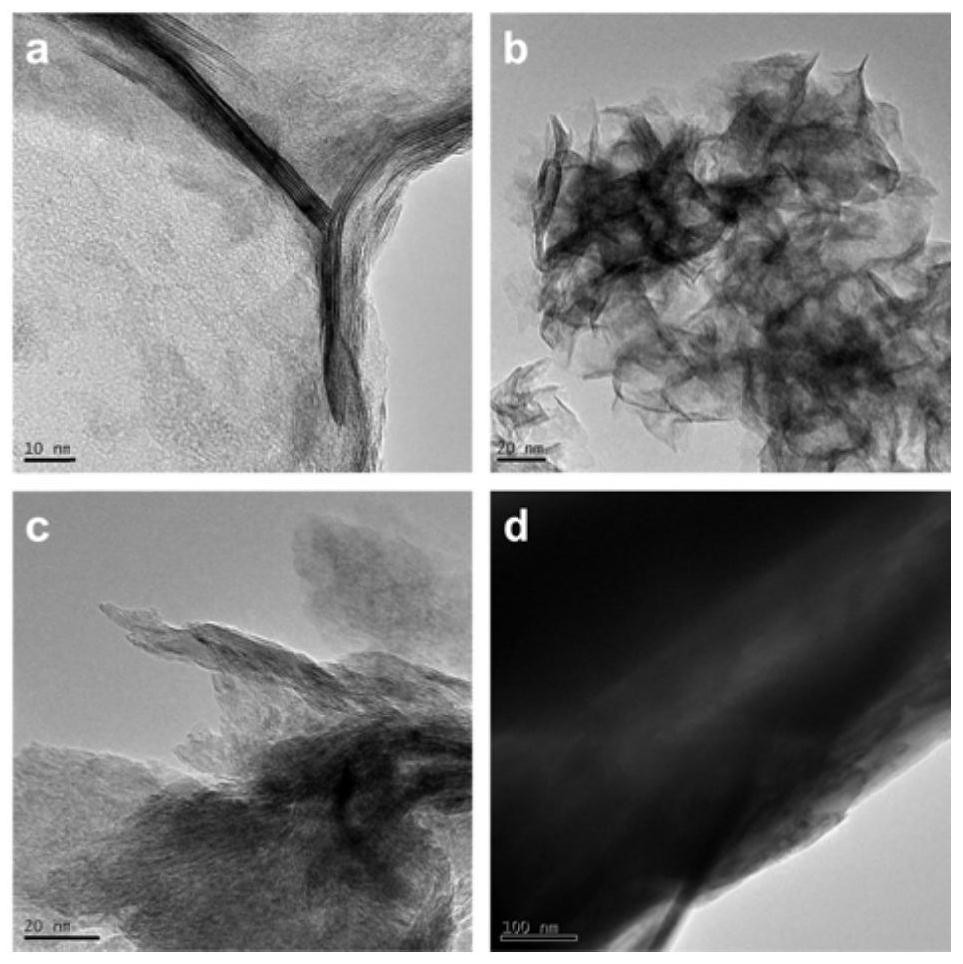

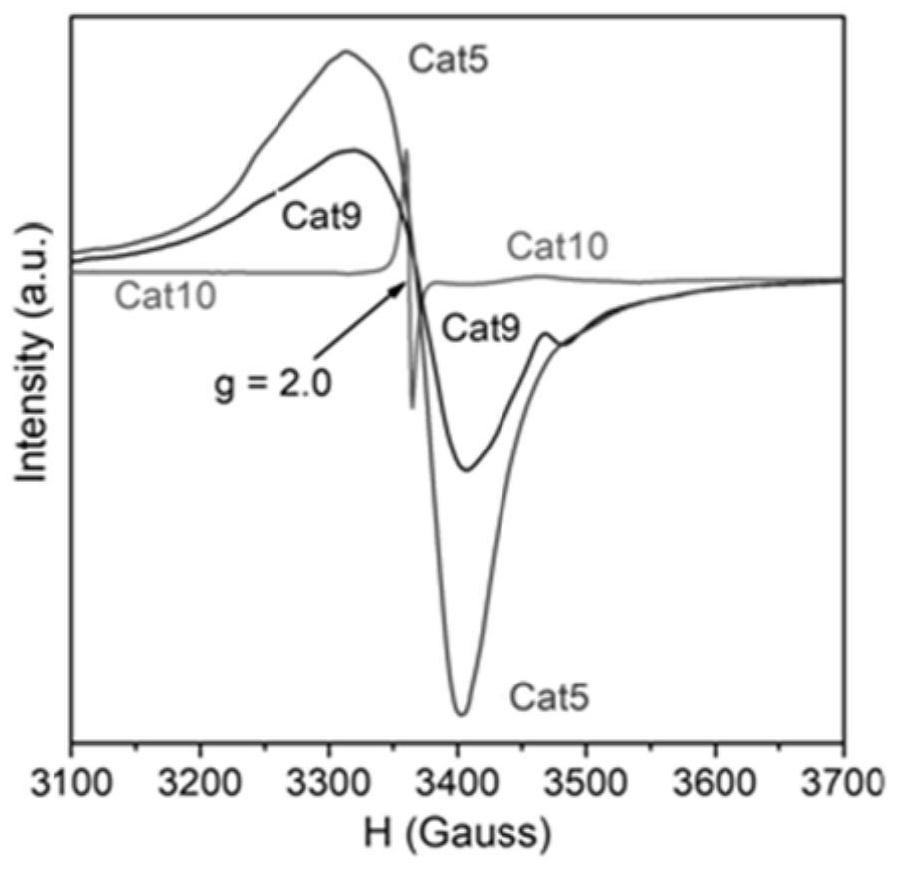

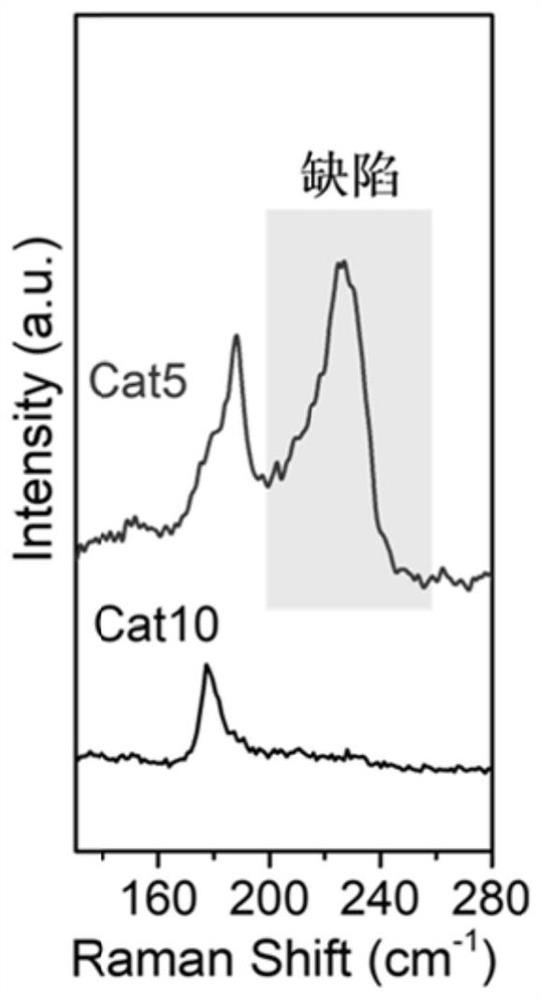

Image

Examples

Embodiment 1

[0034] Dissolve 800mg of ammonium tungstate in water and place in an autoclave, then add 15mL of dimethyl sulfoxide. Seal the autoclave, and pour hydrogen into the autoclave as a reducing agent (dangerous operation), heat the autoclave to 450°C for a high temperature reaction for 3 hours, when the temperature reaches the temperature, the pressure is 10-30 MPa, and cool the autoclave to At room temperature, gas was evolved and the crude product was taken out. The above crude product was alternately washed with ethanol and water until the filtrate was neutral, and dried to obtain Cat1.

Embodiment 2

[0036] Dissolve 400mg of sodium tungstate in water and place in an autoclave, then add 10mL of carbon disulfide. Seal the autoclave, and pour nitrogen into the autoclave as a protective gas, heat the autoclave to 400°C for a high temperature reaction for 4 hours, when the temperature reaches the temperature, the pressure is 10-30MPa, after the reaction is complete, cool the autoclave to room temperature, and release gas The crude product was taken out. The above crude product was alternately washed with ethanol and water until the filtrate was neutral, and then dried to obtain Cat2.

Embodiment 3

[0038] Dissolve 400mg of vanadium chloride in ethanol and place in an autoclave, then add 10mL of carbon disulfide. Seal the high-pressure reactor, and pour nitrogen into the reactor as a protective gas, heat the reactor to 500°C for a high temperature reaction for 3 hours, when the temperature reaches the temperature, the pressure is 10-30MPa, after the reaction is complete, cool the reactor to room temperature, and release gas The crude product was taken out. The above crude product was alternately washed with ethanol and water until the filtrate was neutral, and then dried to obtain Cat3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com