Permanent magnet motor direct-driven large-tonnage carrying device, molten iron transport vehicle and torpedo car

The technology of a permanent magnet motor and a carrier device is applied in the field of permanent magnet motor direct drive large tonnage carrier device, molten iron transport vehicle, and mixed iron truck, and can solve the problem of large temperature drop of molten iron at the interface of iron and steel, waste of equipment resources and energy, and labor cost. Waste and other problems, to achieve the effect of reducing the heat loss of molten iron, ensuring equipment and personal safety, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

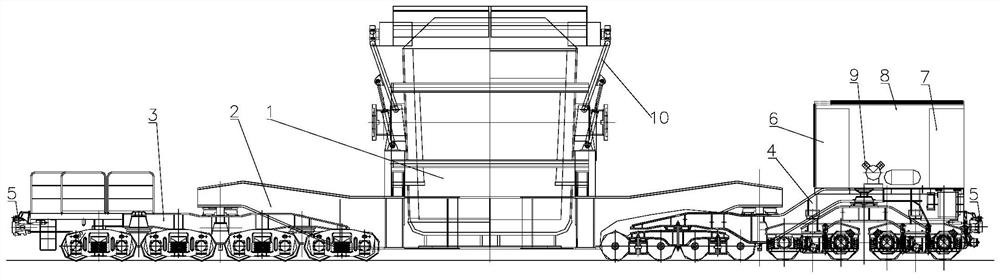

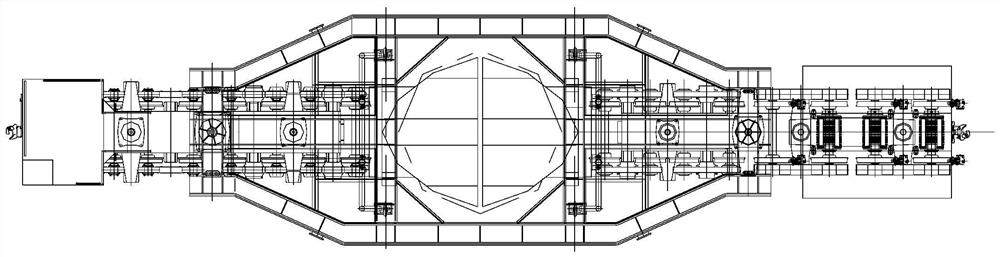

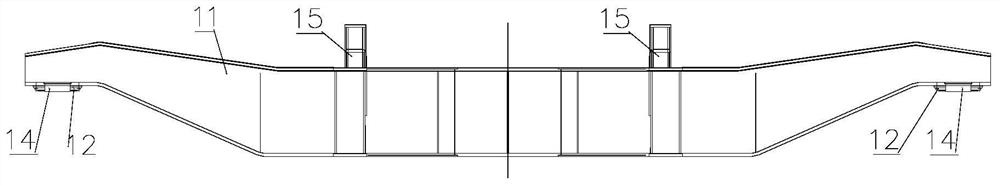

[0059] A permanent magnet motor directly drives a large-tonnage molten iron transport vehicle, such as Figure 1-Figure 5 , Figure 10-Figure 30 As shown, it includes "one-can" molten iron tank 1, large frame 2, driven running device 3, permanent magnet motor direct drive running device 4, connection buffer device with automatic dehook function 5, electrical control system 6, super Capacitor 7, flame-retardant and heat-insulated carport 8, unit braking and parking system 9, heat preservation device 10. The "one-can" molten iron tank 1 is located in the middle and upper part of the vehicle, and the large frame 2 is located in the middle of the vehicle. The two ends of the large frame 2 are respectively connected to the driven running device 3 and the permanent magnet motor direct drive running device 4 through the large center plate. , the driven running device 3 and the permanent magnet motor direct drive running device 4 are equipped with a coupler buffer device 5 with an au...

Embodiment 2

[0071] Such as Figure 6-Figure 30 As shown, a permanent magnet motor directly drives a large tonnage mixed iron car, which includes a mixed iron furnace type molten iron tank 54, a tipping device 55, a driven running device 3, a permanent magnet motor direct drive running device 4, and a belt with automatic hook removal. Functional connection buffer device 5, electrical control system 6, super capacitor 7, flame-retardant and heat-insulated carport 8, unit braking and parking system 9. The mixed iron ladle 54 is located at the middle and upper part of the vehicle, and the tipping device 55 includes a driving end tipping device 56 and a driven end tipping device 57 . The driving end tilting device 56 is installed on the upper part of the running device 3, the driven end tilting device 57 is installed on the upper part of the permanent magnet motor direct drive running device 4, and the driven running device 3 and the permanent magnet motor direct drive running device 4 are loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com