Online treatment system and process for synergy of garbage fly ash and garbage leachate

A technology for landfill leachate and waste fly ash, which is applied to the treatment of combustion products, combustion methods, lighting and heating equipment, etc., and can solve problems such as high disposal difficulty, high toxicity, and difficulty in landfill approval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

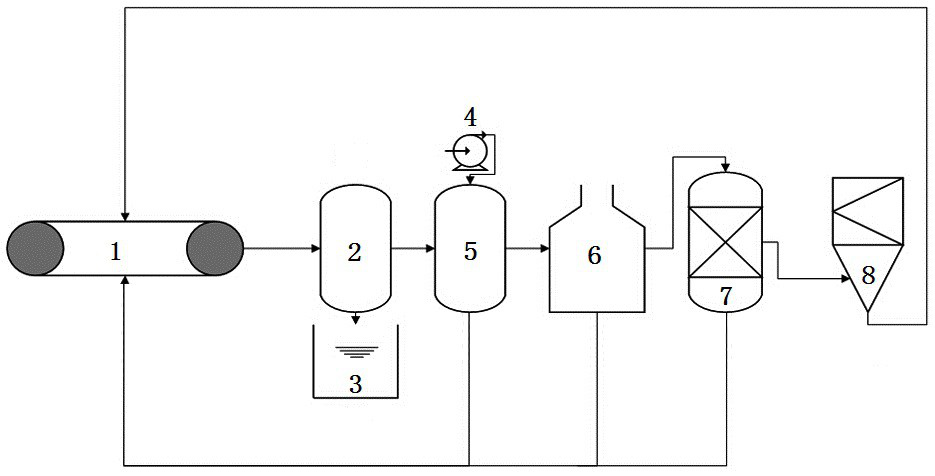

[0037] Example: as attached figure 1 As shown, an online disposal system of garbage fly ash and landfill leachate, including fly ash conveying system 1, plasma melting furnace system 2, slag discharge and slag collection system 3, landfill leachate conveying system 4, secondary combustion chamber and combustion system 5. Waste heat boiler system 6, quenching tower 7, waste incineration plant flue gas purification system 8; fly ash conveying system, plasma melting furnace system, secondary combustion chamber and combustion system, waste heat boiler system, quenching tower, waste incineration plant flue gas purification The systems are connected in sequence, the flue gas purification system of the waste incineration plant is connected to the fly ash conveying system, the slag discharge port of the plasma melting furnace system is connected to the slag discharge and slag collection system, and the landfill leachate conveying system is connected to the secondary combustion chamber ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap