Preparation method of PEDOT: PSS porous reticular membrane structure electrode material for flexible supercapacitor

A technology of supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of restricting the charge storage capacity and low specific surface area of electrode materials, and achieve higher specific capacitance and increased specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method for PEDOT:PSS porous network film structure electrode material for flexible supercapacitor, specifically comprising the following steps:

[0032] (a) Add 5% by volume of polar solvent dimethyl sulfoxide to the conductive polymer PEDOT:PSS aqueous solution, and magnetically stir for 3 hours under the condition of 60°C oil bath, so that the mixed solution reaches 1000-10000CPS;

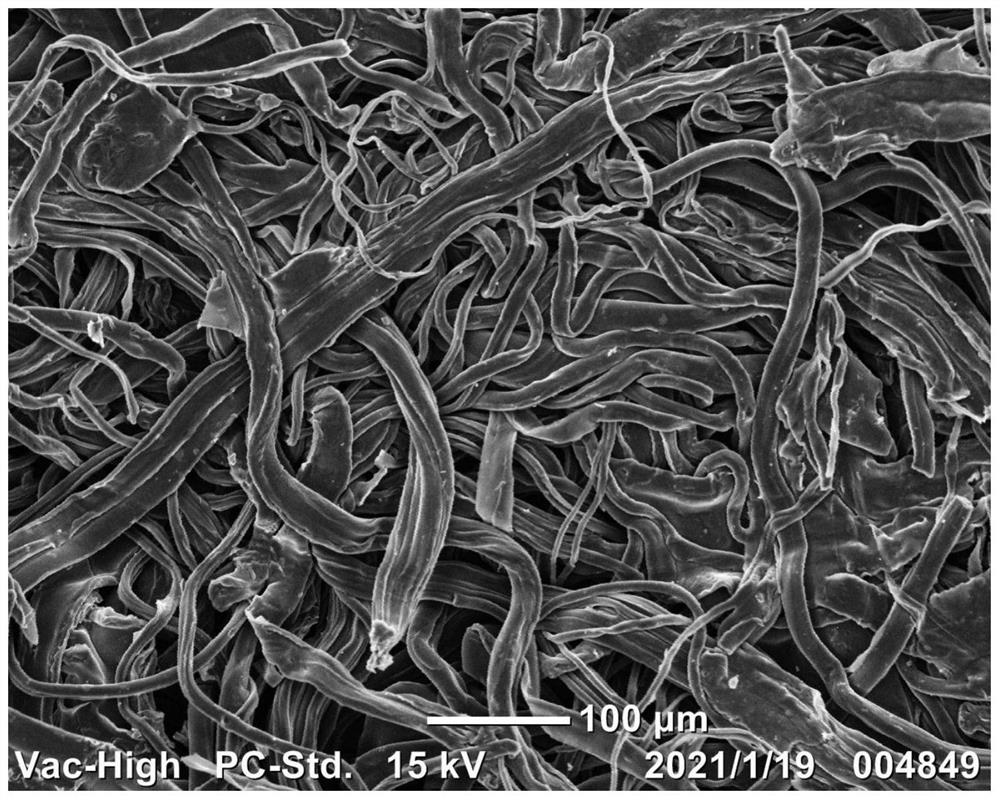

[0033] (b) Inhale the mixed solution prepared in step (a) into the syringe, select a needle with a diameter of 27G to assemble at the end of the syringe, install the syringe on the micro-injection pump, and immerse the outlet of the needle in an organic solvent (isopropanol) to solidify In the bath, set the propulsion speed of the micro-injection pump to 3 μL / h, push the mixed solution from the syringe into the isopropanol coagulation bath, connect the lower part of the coagulation bath to the turntable, adjust the speed of the turntable to 2rad / min, and obtain in the coagulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com