Ternary cyano framework material as well as preparation method and application thereof

A frame material, cyano-based technology, applied in chemical instruments and methods, electrical components, inorganic chemistry, etc., can solve the problems of not having comprehensive performance at the same time, gap in general theoretical value of capacity, unsatisfactory cycle performance, etc., and achieve excellent rate performance And cycle performance, excellent rate performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Mix sodium ferrocyanide and deionized water to obtain solution I with a concentration of 0.1mol / L; dissolve manganese sulfate, ferrous sulfate, and nickel sulfate in deionized water at a molar ratio of 6:2:2, and then add sodium sulfate , sodium citrate obtain solution II, wherein manganese sulfate, ferrous sulfate, nickel sulfate total molar concentration is 0.1mol / L, and the molar concentration of sodium citrate is 0.4mol / L, and sodium sulfate is a saturated solution; Solution I is dripped into Into solution II, a precipitate is obtained through co-precipitation reaction; Na is obtained through sufficient stirring, aging and post-treatment 2 mn 0.6 Fe 0.2 Ni 0.2 [Fe(CN) 6 ] Ternary cyano frame material.

[0055] After testing, the particle size is 0.5-1 μm.

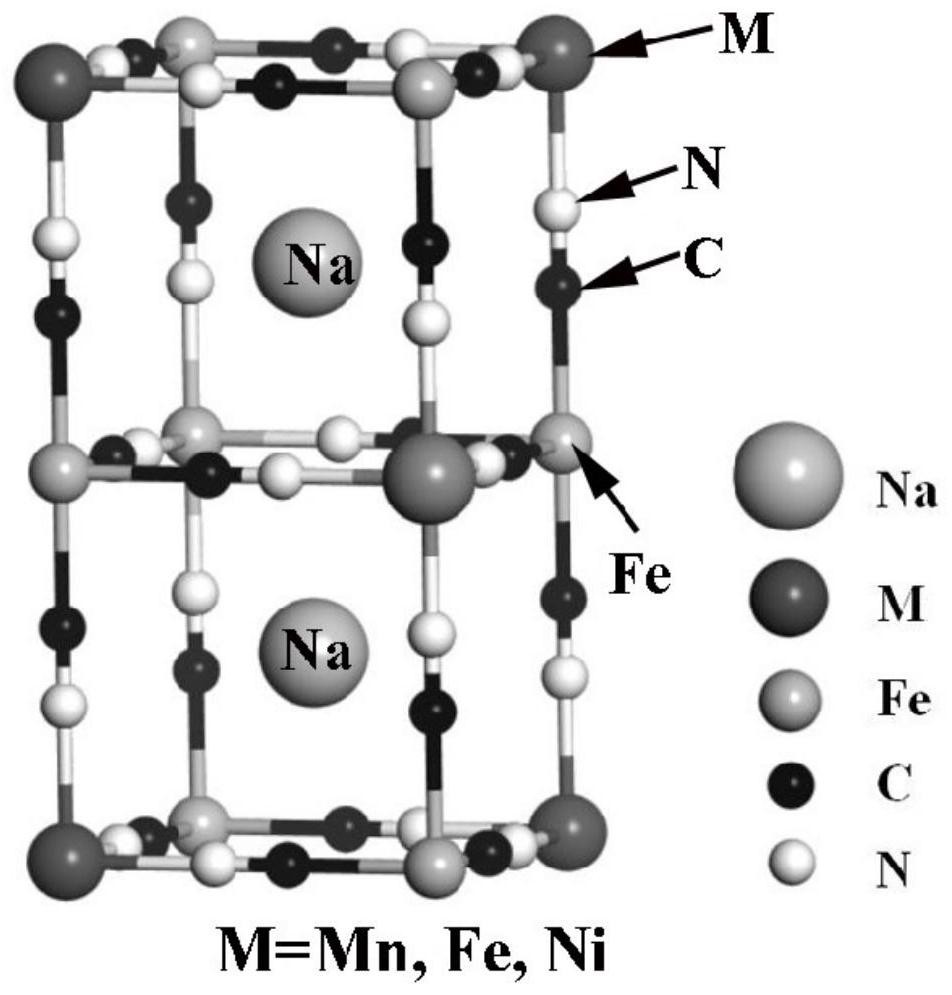

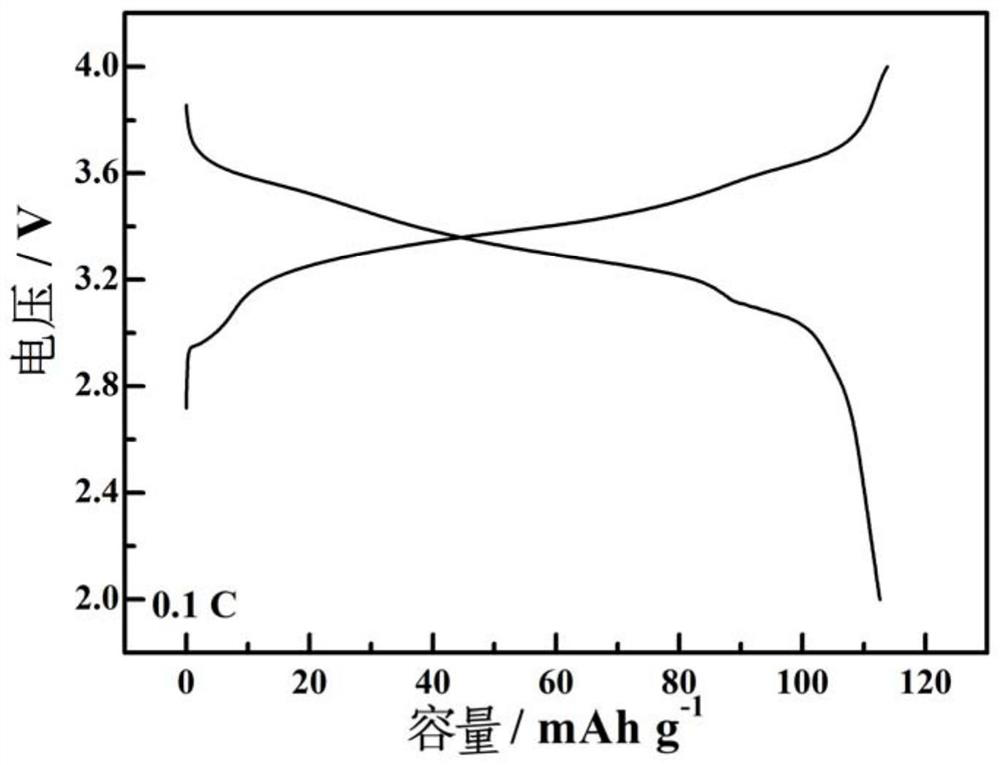

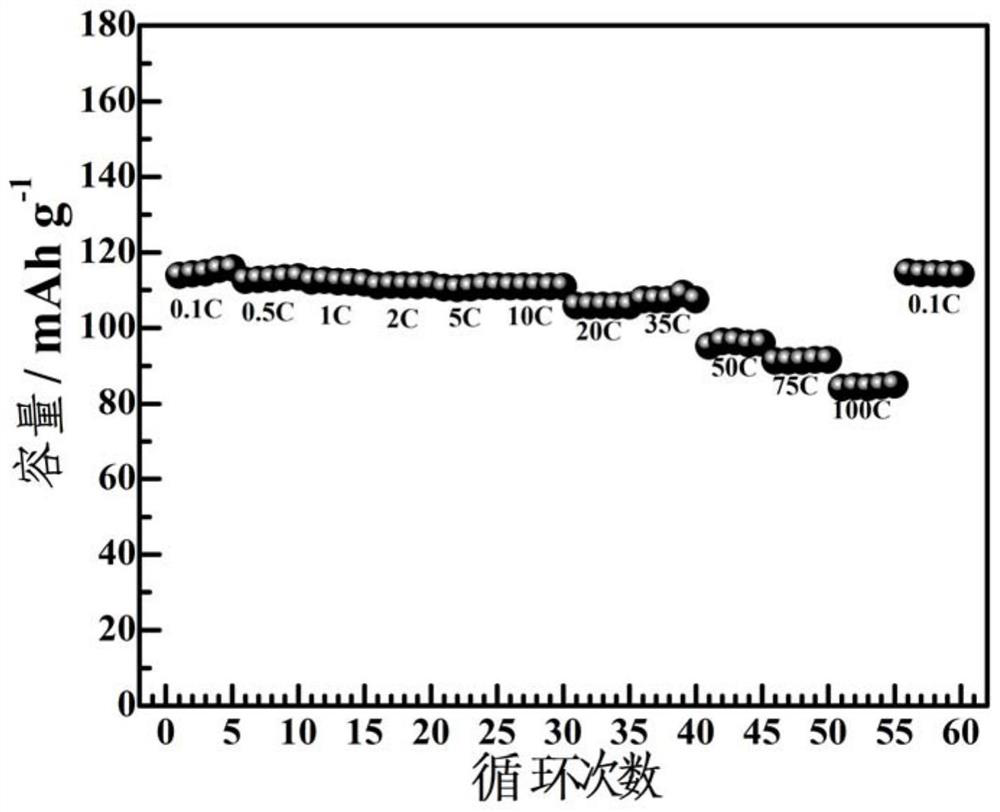

[0056] figure 1 Schematic diagram of the structure of the ternary cyanide framework material prepared for this example. In the figure, manganese, nickel, and iron atoms (from divalent soluble salts) are con...

Embodiment 2

[0071] Mix sodium ferrocyanide and deionized water to obtain solution I with a concentration of 0.2mol / L; dissolve manganese sulfate, ferrous sulfate, and nickel sulfate in deionized water at a molar ratio of 5:3:2, and then add sodium sulfate , sodium citrate obtain solution II, wherein manganese sulfate, ferrous sulfate, nickel sulfate total molar concentration is 0.2mol / L, and the molar concentration of sodium citrate is 1.2mol / L, and sodium sulfate is a saturated solution; Solution I is dripped into into solution II, precipitated by co-precipitation reaction; fully stirred, aged and post-treated to obtain Na 2 mn 0.5 Fe 0.3 Ni 0.2 [Fe(CN) 6 ] Ternary cyano frame material.

[0072] After testing, the particle size is 0.5-1 μm.

[0073] The battery is assembled in exactly the same way as in Example 1, and the electrochemical test is carried out under the same conditions. The current density is 0.1C, and the initial discharge capacity of the product can reach 115mAh / g. W...

Embodiment 3

[0075] Mix potassium ferrocyanide with deionized water to obtain solution I with a concentration of 0.2mol / L; dissolve manganese sulfate, ferrous sulfate, and nickel sulfate in deionized water at a molar ratio of 4:4:2, and then add chloride Potassium, potassium citrate obtain solution II, wherein manganese sulfate, ferrous sulfate, nickel sulfate total molar concentration are 0.2mol / L, and the molar concentration of potassium citrate is 0.5mol / L, and Repone K is a saturated solution; Solution I Dropped into solution II, precipitated by co-precipitation reaction; fully stirred, aged and post-treated to obtain K 2 mn 0.4 Fe 0.4 Ni 0.2 [Fe(CN) 6 ] Ternary cyano frame material.

[0076] After testing, the particle size is 0.5-1 μm.

[0077] The battery is assembled in exactly the same way as in Example 1, and the electrochemical test is carried out under the same conditions. The current density is 0.1C, and the initial discharge capacity of the product can reach 110mAh / g. Wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com