High-viscous-force weather-resistant hot melt adhesive and preparation method thereof

A hot-melt adhesive and weather-resistant technology, used in non-polymer adhesive additives, adhesives, photovoltaic power generation and other directions, can solve the problems of difficulty in meeting the needs of use, unfavorable long-term use, general weather resistance, etc., to achieve good weather resistance, conducive to Long-term use and improved weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

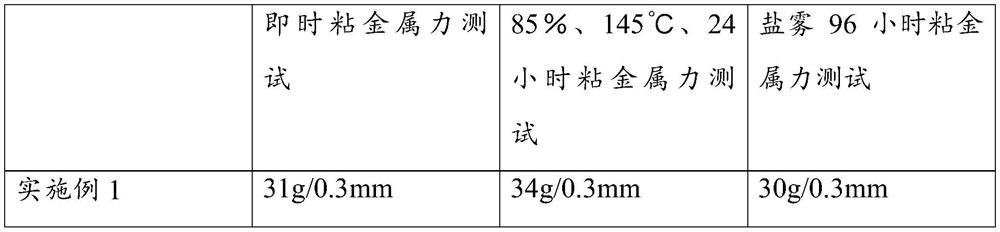

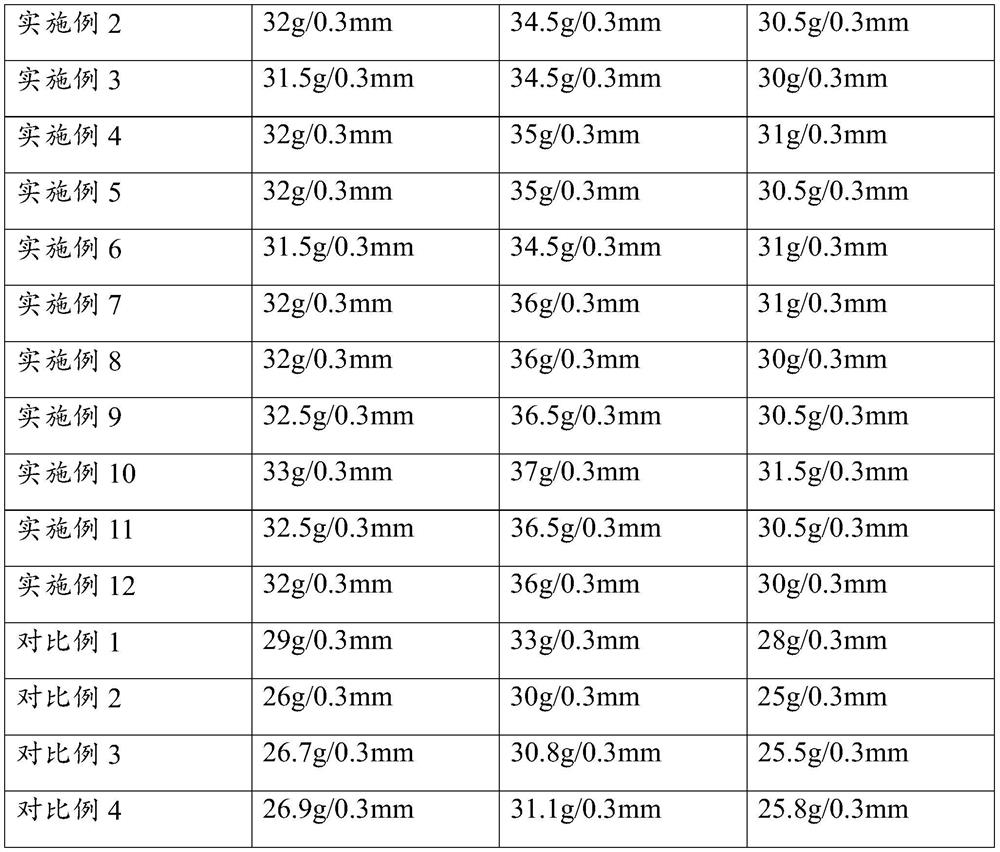

Examples

Embodiment 1

[0023] A preparation method of a high-viscosity weather-resistant hot-melt adhesive, specifically comprising the following steps:

[0024] (1) Preparation of modified titanium dioxide: first, pulverize and grind titanium dioxide, pass through a 200-mesh sieve, and then put the pulverized titanium dioxide powder, polysiloxane and hexyl diethylaminohydroxybenzoylbenzoate into the mixing tank In, make the total mass of polysiloxane and diethylaminohydroxybenzoyl hexyl benzoate be 40% of titanium dioxide powder mass, between polysiloxane and diethylaminohydroxybenzoyl hexyl benzoate The mass ratio is 1.3:1. Under the condition of 60°C, mix and stir so that the rotation speed is 180r / min, stir for 60min, then dry, pulverize, and pulverize through a 150-mesh sieve to obtain modified titanium dioxide;

[0025] (2) Weigh the corresponding weight of raw materials: ethylene-vinyl acetate copolymer 500g, modified titanium dioxide 60g, antioxidant 2g, tackifier 100g, coupling agent 6g, le...

Embodiment 2

[0027] A preparation method of a high-viscosity weather-resistant hot-melt adhesive, specifically comprising the following steps:

[0028] (1) Preparation of modified titanium dioxide: first, pulverize and grind titanium dioxide, pass through a 200-mesh sieve, and then put the pulverized titanium dioxide powder, polysiloxane and hexyl diethylaminohydroxybenzoylbenzoate into the mixing tank In, make the total mass of polysiloxane and diethylaminohydroxybenzoyl hexyl benzoate be 50% of titanium dioxide powder quality, between polysiloxane and diethylaminohydroxybenzoyl hexyl benzoate The mass ratio is 1.3:1. Mix and stir at 70°C so that the rotation speed is 200r / min, stir for 80min, then dry, pulverize, and pass through a 150-mesh sieve to obtain modified titanium dioxide;

[0029] (2) Weigh the corresponding weight of raw materials: ethylene-vinyl acetate copolymer 700g, modified titanium dioxide 80g, antioxidant 4g, tackifier 140g, coupling agent 8g, leveling agent 14g, plast...

Embodiment 3

[0031] A preparation method of a high-viscosity weather-resistant hot-melt adhesive, specifically comprising the following steps:

[0032] (1) Preparation of modified titanium dioxide: first, pulverize and grind titanium dioxide, pass through a 200-mesh sieve, and then put the pulverized titanium dioxide powder, polysiloxane and hexyl diethylaminohydroxybenzoylbenzoate into the mixing tank In, make the total mass of polysiloxane and diethylaminohydroxybenzoyl hexyl benzoate be 45% of titanium dioxide powder quality, between polysiloxane and diethylaminohydroxybenzoyl hexyl benzoate The mass ratio is 1.3:1. Under the condition of 65°C, mix and stir so that the rotation speed is 190r / min, stir for 70min, then dry, pulverize, and pulverize through a 150-mesh sieve to obtain modified titanium dioxide;

[0033] (2) Weigh the corresponding weight of raw materials: ethylene-vinyl acetate copolymer 550g, modified titanium dioxide 65g, antioxidant 2.5g, tackifier 110g, coupling agent 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com