Sodium ion secondary battery and preparation method thereof

A secondary battery, sodium ion technology, applied in secondary batteries, battery electrodes, non-aqueous electrolyte battery electrodes, etc., can solve problems such as affecting the high rate performance of electrode materials, irreversible changes in the lattice structure of materials, and affecting the performance of electrode materials. , to achieve the effect of improving fast charge and discharge performance, improving electrochemical performance and high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

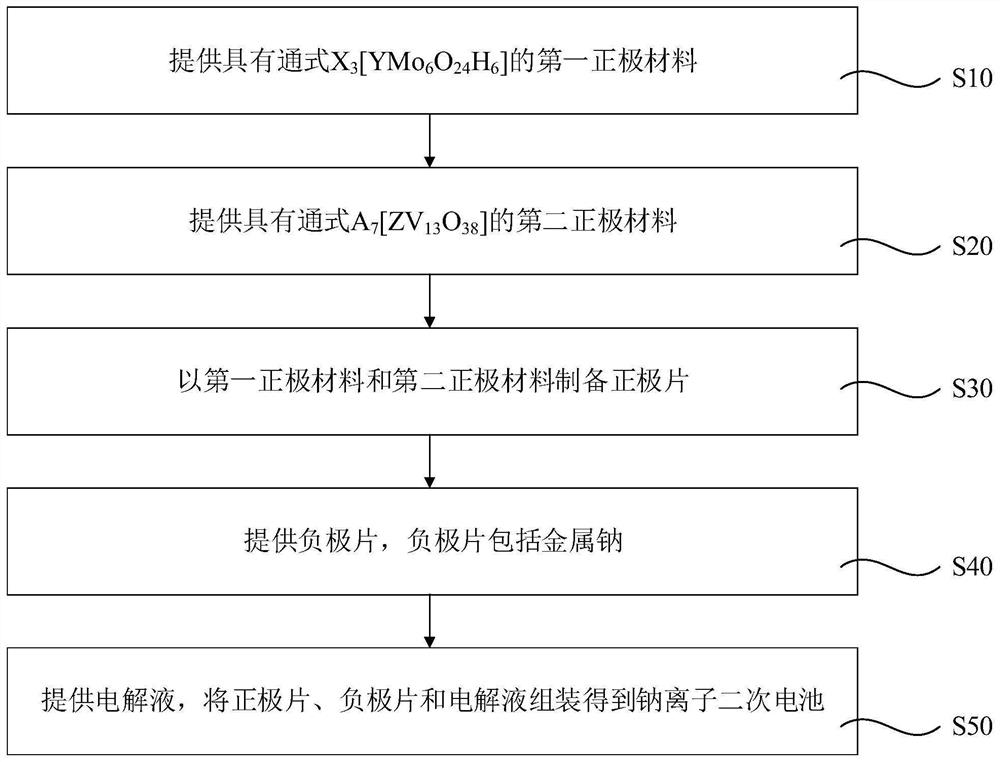

[0040] combine figure 1 , the present invention also provides a method for preparing the above-mentioned sodium ion secondary battery in an embodiment, comprising the following steps:

[0041] S10, providing a formula X 3 [YMo 6 o 24 h 6 ] as the first cathode material.

[0042] Among them, X is NH 4 , Li, Na or K, Y is Al, Ni, Co, Mn or Fe.

[0043] Specifically, the first positive electrode material can be prepared by the following operations: to YCl 3 Add X to the solution 2 MoO 4 2H 2 O, then use hydrochloric acid (preferably 35 wt% hydrochloric acid) to adjust the pH of the solution to 1.8, and heat and evaporate (preferably 80° C.) to obtain the first positive electrode material.

[0044] S20, providing a formula A 7 [ZV 13 o 38 ] as the second cathode material.

[0045] Among them, A is NH 4 , Li, Na or K, Z=Ni, Co or Mn.

[0046] to AVO 3 Add HNO to the solution 3 、ZSO 4 and K 2 S 2 o 8 The mixed liquid is obtained, and the second positive electro...

Embodiment 1

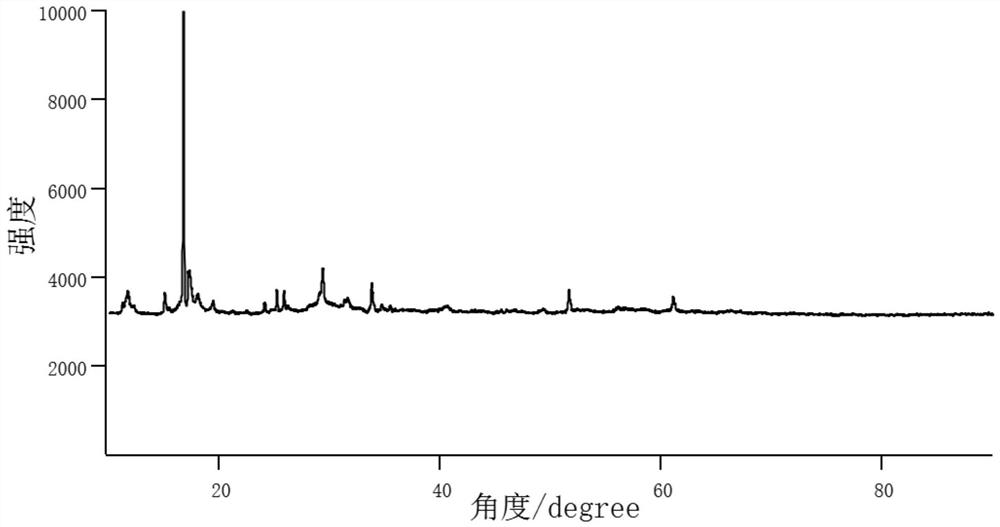

[0063] 0.829g AlCl 3 Dissolve in 25mL deionized water, add 3.5g (NH 4 ) 2 MoO 4 2H 2 O, adjust the pH value of the solution to 1.8 with 35% HCl, and heat and evaporate. After the solvent evaporates, a solid crystal is obtained. The solid crystalline product has molecular formula (NH 4 ) 3 [AlMo 6 o 24 h 6 ]’s first positive electrode material, the XRD diffraction pattern of its crystal structure is as follows figure 2 shown.

[0064] Depend on figure 2 It can be seen that the first positive electrode material has a crystal structure, and the corresponding crystal interior has multi-dimensional space channels required for the transmission of large-sized sodium ions.

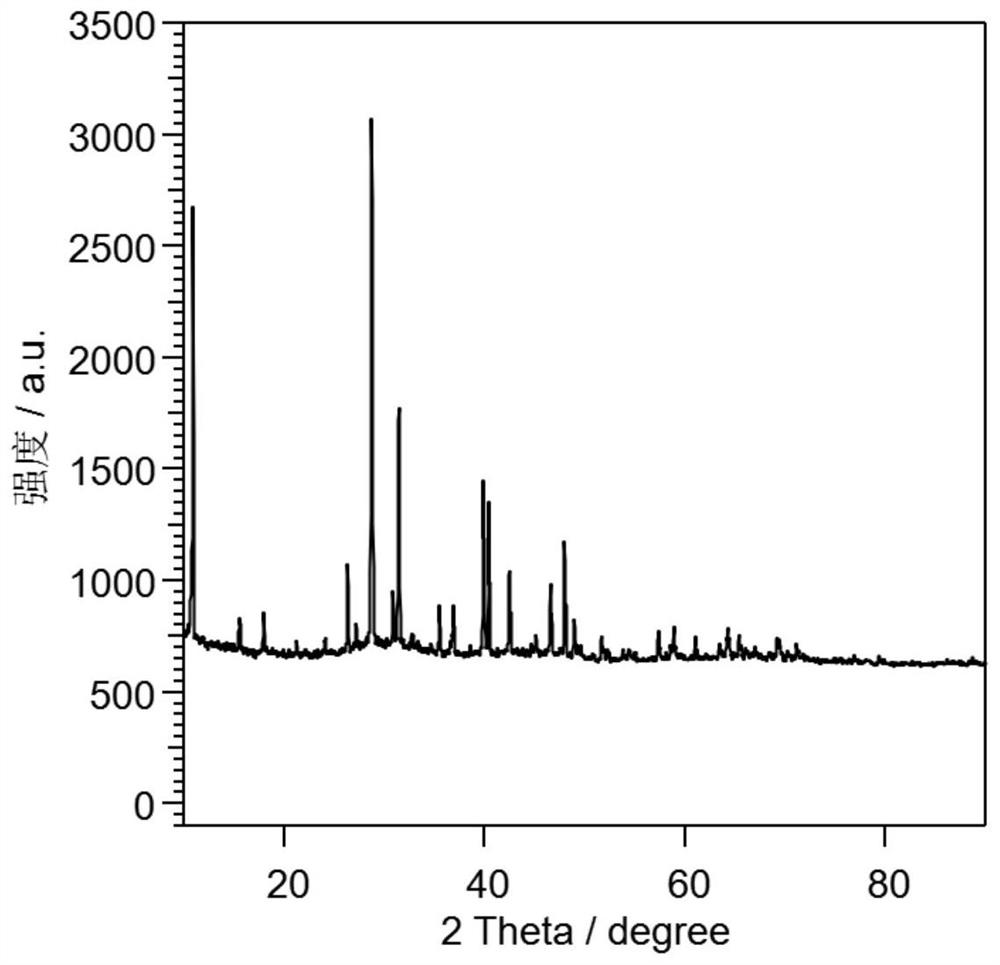

[0065] 7.18g KVO 3 Dissolve in 180mL deionized water at 80°C, add 4mL 1mol / L HNO 3 , 4mL1mol / L of MnSO 4 and 2.16g of K 2 S 2 o 8 , the mixed solution was stirred at a temperature of 80° C. until the solvent evaporated, and a solid crystal was obtained. The solid crystal has the molecular formu...

Embodiment 2

[0070] The recrystallization particle that embodiment 1 makes: Conductive carbon black: Positive pole binder (PVDF) is carried out slurry preparation, coating, drying, roll pressing, cutting piece by the mass percentage of 50%: 30%: 20% , to obtain the positive electrode sheet. EC:DMC=1:1 (volume ratio)+1mol / L NaClO 4 As the electrolyte, sodium metal as the negative electrode, assembled into a button battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com