Screw type filter assembly

A filter element and spiral technology, which is applied in the field of heavy metal non-eluting spiral filter elements, can solve safety problems and other problems, and achieve the effect of reducing the concentration of heavy metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] Terephthalic acid (TPA, terephthalic acid) as an acid component compound and 1,4-butandiol (1,4-butandiol) as a diol component compound are mixed at a molar ratio of 1:1.5, with respect to 100 wt. parts, add 150 ppm of a titanium-based catalyst represented by the following chemical formula 2, perform an esterification reaction at a temperature of 270° C. and a pressure of 1200 torr, and then depressurize the pressure to 0.5 torr, and perform a polycondensation reaction at 270° C., thereby producing Core polyester resin with a melting point of 255°C.

[0102] chemical formula 2

[0103] (M 2 O) 0.01 (TiO 2 )[(CH 2 ) 8 OH] 20

[0104] Terephthalic acid (TPA, terephthalic acid) as an acid component compound and 1,2-ethylene glycol as a diol component compound were mixed at a molar ratio of 1:1, and the above chemical formula was added to 100 parts by weight of the above mixture. The catalyst represented by 2 is 150ppm, the esterification reaction is carried out at ...

Embodiment 2 to 9

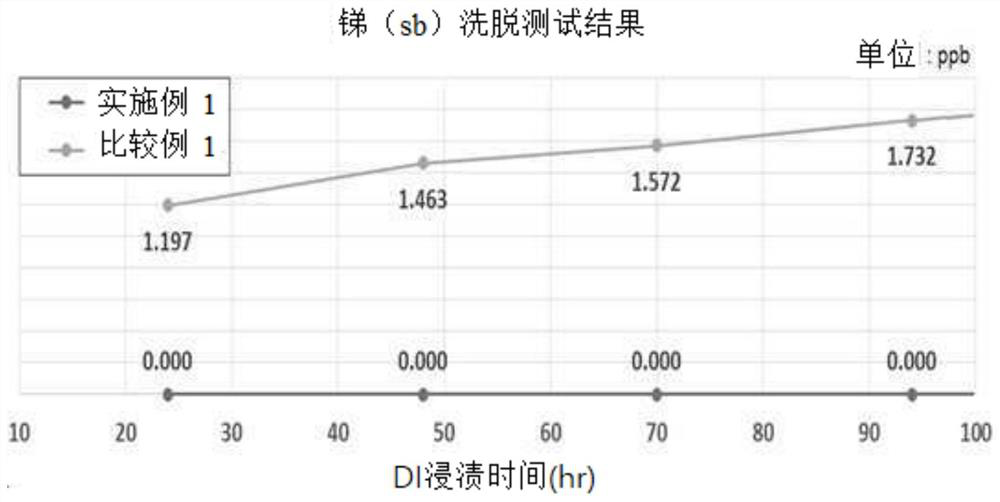

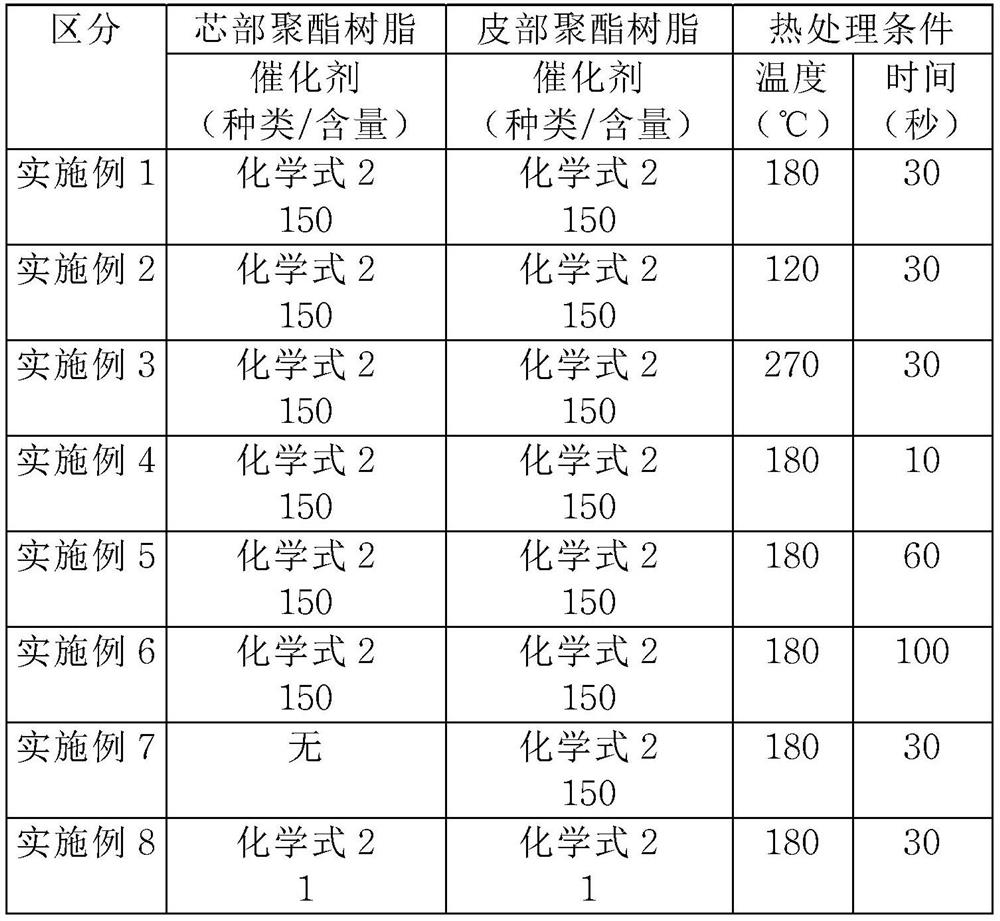

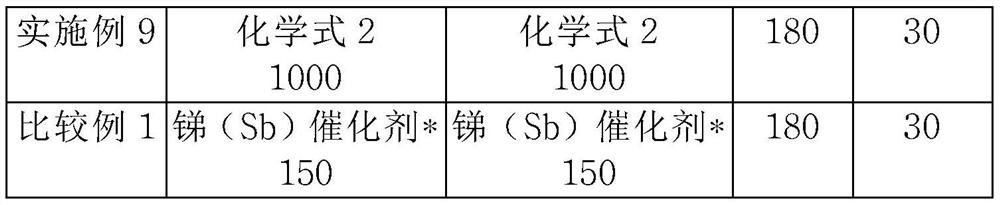

[0107] Examples 2 to 9 and comparative examples

[0108] In the same manner as in Example 1, heavy metal non-eluting fabrics with different conditions as shown in Table 1 were produced.

[0109] Table 1

[0110]

[0111]

experiment example 1

[0114] Experimental Example 1: Strength Test

[0115] The bonding strength of warp-knitted fabrics manufactured according to Examples and Comparative Examples was measured. Specifically, prepare samples of the warp-knitted fabrics of Examples and Comparative Examples with a size of 100mm (L) × 20mm (W) × 10mm (D), and use a fiber tensile testing machine (UMT, Instron) ), it was measured 15 times with a tensile speed of 500mm / min. The average of 13 determinations except for the maximum value and the minimum value among the determination values was analyzed to determine the bond strength value. This is shown in Table 2 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com