Integrated sewage treatment system

A sewage treatment system and an integrated technology, applied in the field of water treatment, can solve problems such as complex operation and process control, troublesome sludge management, and large land occupation, and achieve compact treatment units, improved biodegradability, and effective biomass Guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The sewage flow rate is 1m3 / d, the BOD5 is 200mg / L, and the ammonia nitrogen concentration is 40mg / L.

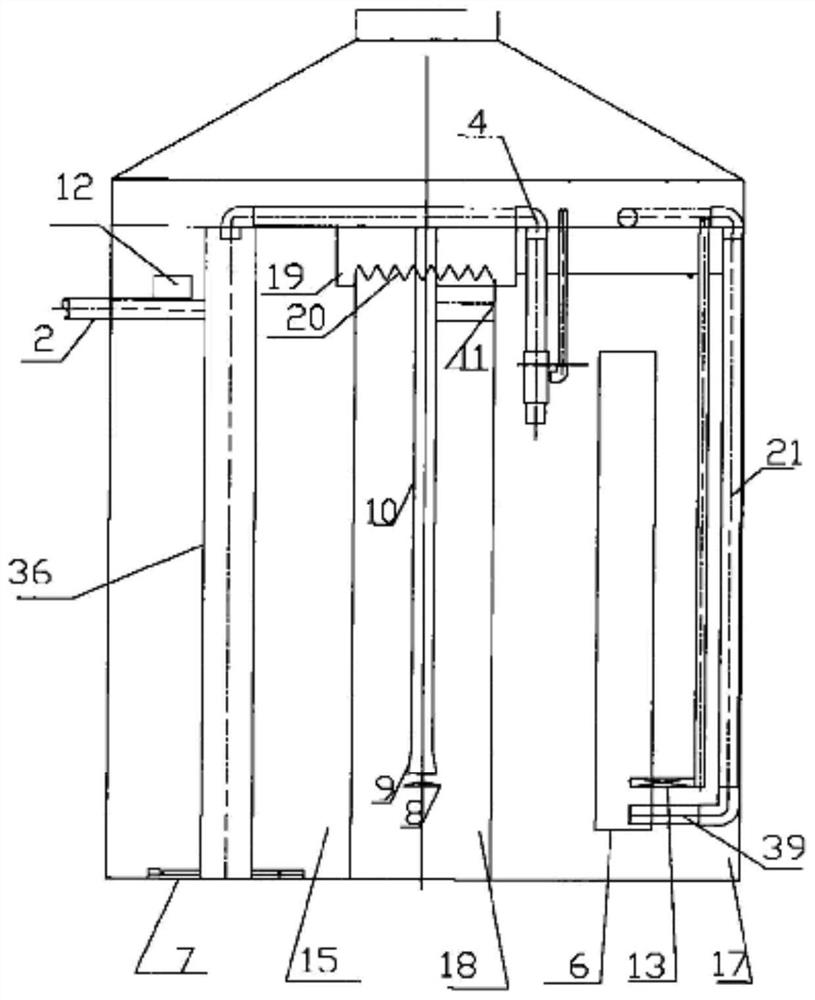

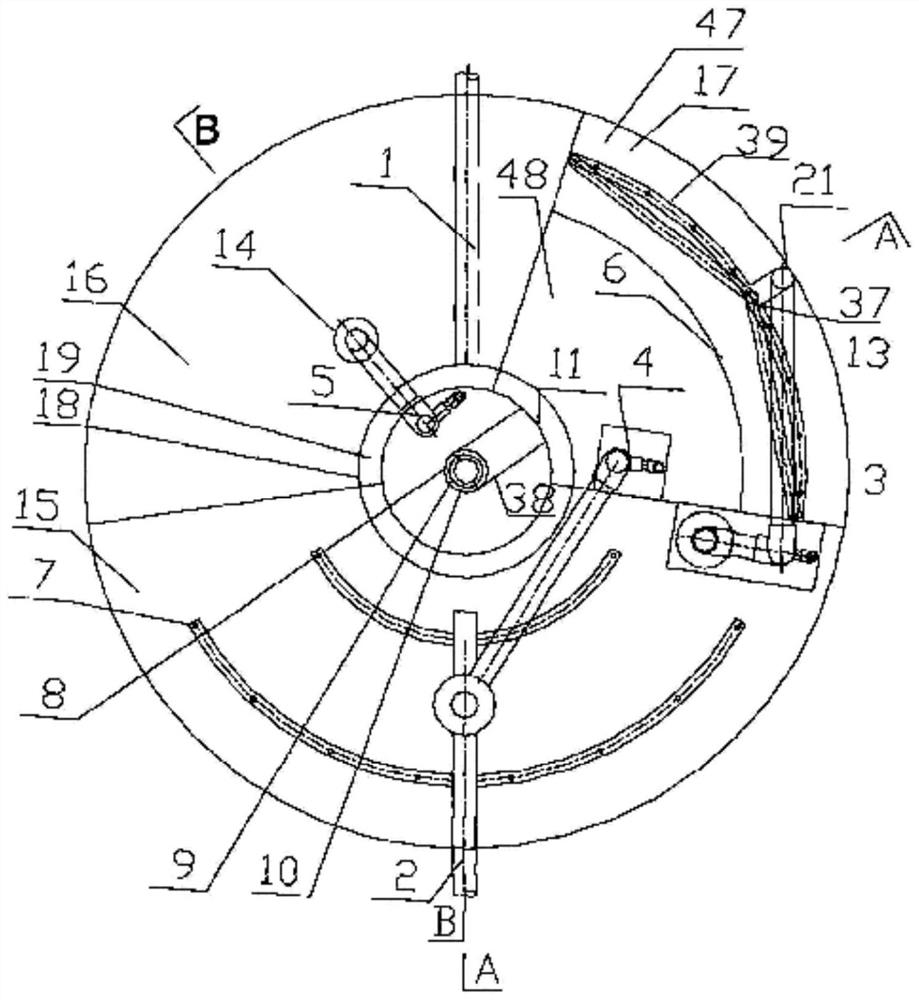

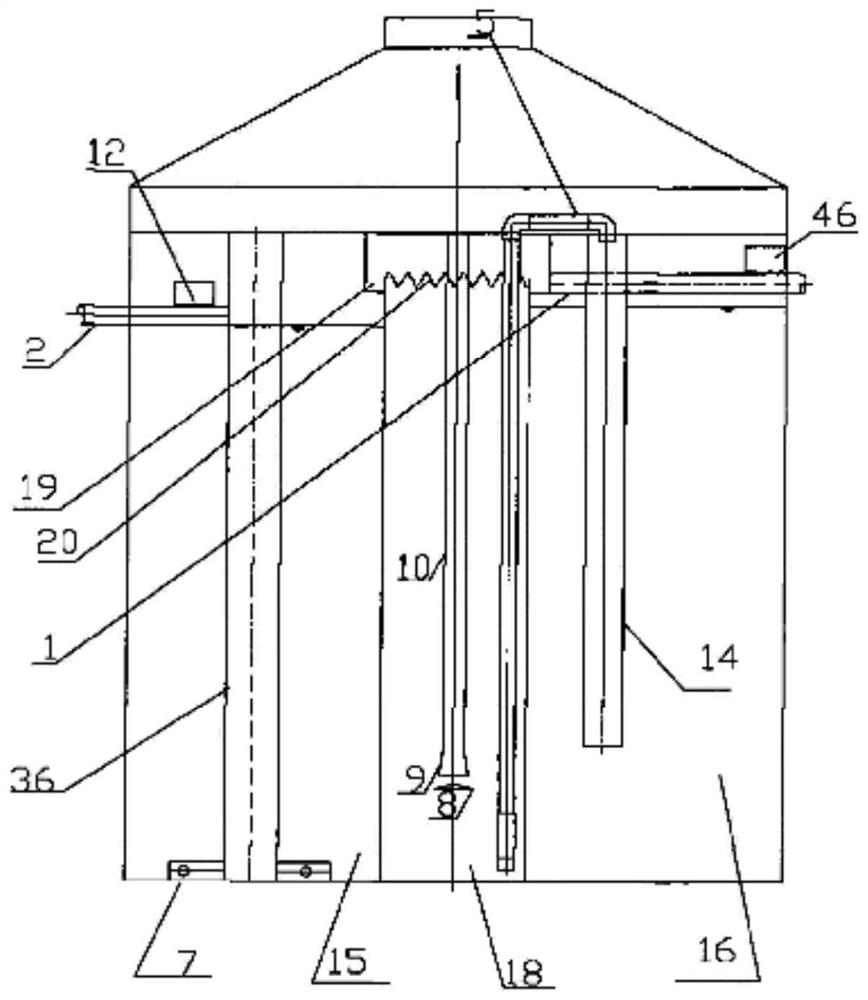

[0033] As shown in Figure 1-3, an integrated integrated sewage treatment system has an effective volume of 1.94m3, the entire reactor plane is circular with an area of 1.39m2, an effective height of 1.4m, and an aspect ratio of 1.1. The reactor integrates four functional units including the anoxic biological adjustment tank 15, the suspended filler biological reaction tank 17, the secondary sedimentation tank 18, and the mud storage tank 16. The volumes are 0.83m3, 0.42m3, 0.10m3, and 0.59m3 respectively. . The secondary settling tank 18 is placed in the middle of the reactor, and the other three functional units surround the central secondary settling tank 18 radially.

[0034] The anoxic biological adjustment tank 15 includes a main water inlet pipe 2, a water collection pipe 36, a first arc-shaped perforated water distribution pipe 7, and a sewage air lifter 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com