External wall anti-crack mortar

An anti-cracking mortar and exterior wall technology, applied in the field of building materials, can solve the problems of complex process and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

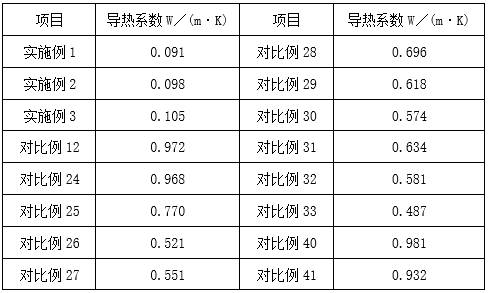

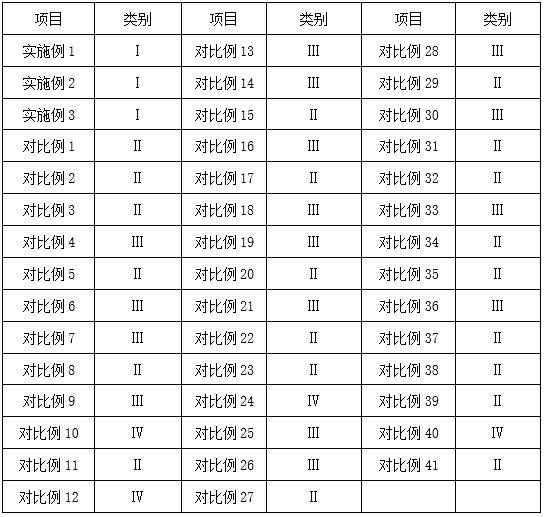

Examples

Embodiment 1

[0050] An anti-cracking mortar for external walls, raw materials include P.O42.5 cement: 325 parts, machine-made sand: 650 parts, 325 mesh heavy calcium powder: 25 parts, cellulose ether: 4 parts, modified fiber: 4 parts, latex Powder: 15 parts, modified sealing agent 2 parts.

[0051] The modified fiber is: 20 parts of polypropylene fiber, 33 parts of lignin fiber, 13 parts of steel nanofiber, 13 parts of brucite fiber, 13 parts of sepiolite fiber, 10 parts of 10mm carbon fiber, 7 parts of 6mm basalt fiber Modified after mixing.

[0052] Wherein, the specific modification process of the fiber is as follows:

[0053] 1) Cut polypropylene fibers, steel nanofibers, and brucite fibers into 10mm-long chopped fibers, add lignin fibers, sepiolite fibers, 10mm carbon fibers, and 6mm basalt fibers to them, and mix them according to the proportion well mixed;

[0054] 2) Soak the above uniformly mixed fibers in the sol solution, slowly raise the temperature to 73°C at a rate of 2°C / ...

Embodiment 2

[0078] An anti-cracking mortar for external walls, raw materials include P.O42.5 cement: 300 parts, machine-made sand: 650 parts, 325 mesh heavy calcium powder: 50 parts, cellulose ether: 3 parts, modified fiber: 5 parts, latex Powder: 12 parts, modified sealing agent 3 parts.

[0079] The modified fiber is: 25 parts of polypropylene fiber, 30 parts of lignin fiber, 15 parts of steel nanofiber, 10 parts of brucite fiber, 15 parts of sepiolite fiber, 5 parts of 10mm carbon fiber, and 8 parts of 6mm basalt fiber Modified after mixing.

[0080] Wherein, the specific modification process of the fiber is as follows:

[0081] 1) Cut polypropylene fibers, steel nanofibers, and brucite fibers into 10mm-long chopped fibers, add lignin fibers, sepiolite fibers, 10mm carbon fibers, and 6mm basalt fibers to them, and mix them according to the proportion well mixed;

[0082] 2) Soak the uniformly mixed fibers above in the sol solution, slowly raise the temperature to 70°C at a rate of 3°C...

Embodiment 3

[0106] An anti-crack mortar for external walls, raw materials include P.O42.5 cement: 350 parts, machine-made sand: 650 parts, cellulose ether: 5 parts, modified fiber: 3 parts, latex powder: 18 parts, modified solidification 1 dose.

[0107] The modified fiber is: 15 parts of polypropylene fiber, 35 parts of lignin fiber, 10 parts of steel nanofiber, 15 parts of brucite fiber, 10 parts of sepiolite fiber, 15 parts of 10mm carbon fiber, 5 parts of 6mm basalt fiber Modified after mixing.

[0108] Wherein, the specific modification process of the fiber is as follows:

[0109] 1) Cut polypropylene fibers, steel nanofibers, and brucite fibers into 10mm-long chopped fibers, add lignin fibers, sepiolite fibers, 10mm carbon fibers, and 6mm basalt fibers to them, and mix them according to the proportion well mixed;

[0110] 2) Soak the uniformly mixed fibers above in the sol solution, slowly raise the temperature to 75°C at a rate of 1°C / min, keep warm for 3 hours, and carry out pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com