Laser quenching light absorption coating with heat preservation function and preparation method thereof

A technology of laser quenching and light-absorbing coatings, which is applied in the direction of radiation-absorbing coatings and coatings, can solve the problems of large heat loss, shallow hardened layer, poor heat preservation effect and light-absorbing performance, and achieve high melting point, large resistivity, thermal good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

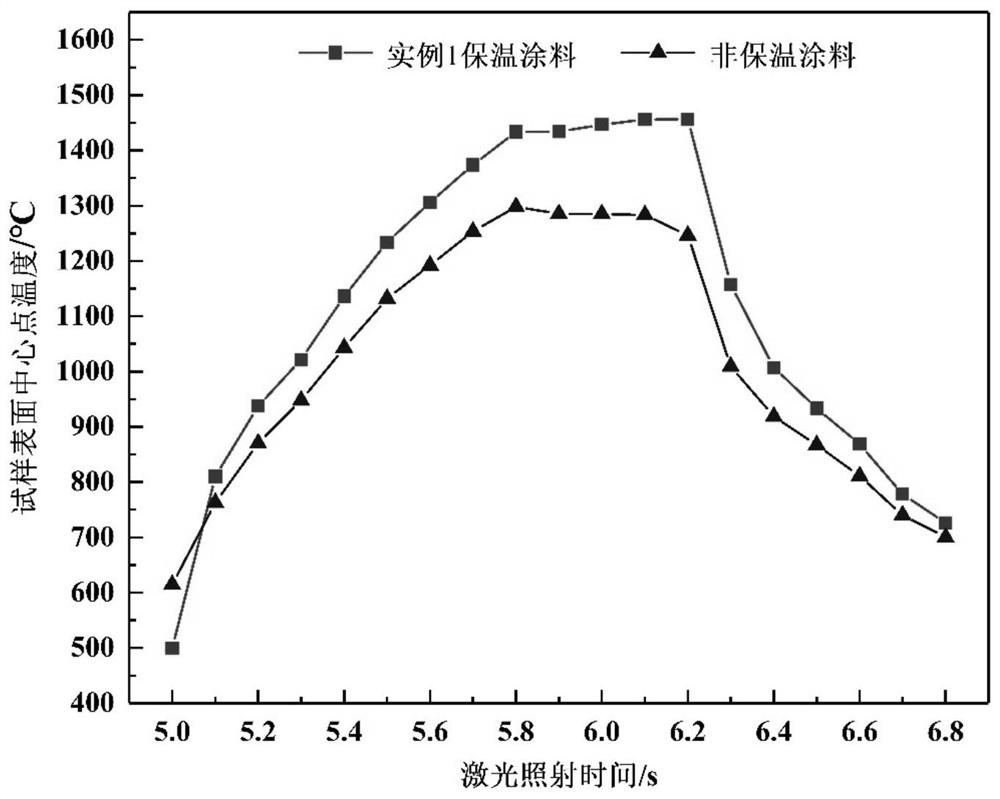

Embodiment 1

[0035] A laser quenching light-absorbing coating with thermal insulation function and a preparation method thereof, comprising the following steps:

[0036] (1) Prepare a uniform heat-insulating light-absorbing coating:

[0037] S1: Pour 1 part of zirconium dioxide, 8 parts of rare earth rhenium and 6 parts of carbon black into a ball mill for ball milling, with a particle size of more than 2000 mesh;

[0038] S2: Fully dissolve and stir 61 parts of benzene-free banana water and 23 parts of thermoplastic acrylic varnish;

[0039] S3: 1 part of zirconium dioxide, 8 parts of rare earth rhenium and 6 parts of carbon black mixture after ball milling in step S1, 61 parts of benzene-free banana water and 23 parts of thermoplastic acrylic varnish auxiliary materials dissolved and stirred in step S2 are fully mixed and stirred;

[0040] S4: Pour 1 part of ethyl cellulose into the mixed material after stirring in S3 to fully mix and stir.

[0041] (2) Coating the above-mentioned nove...

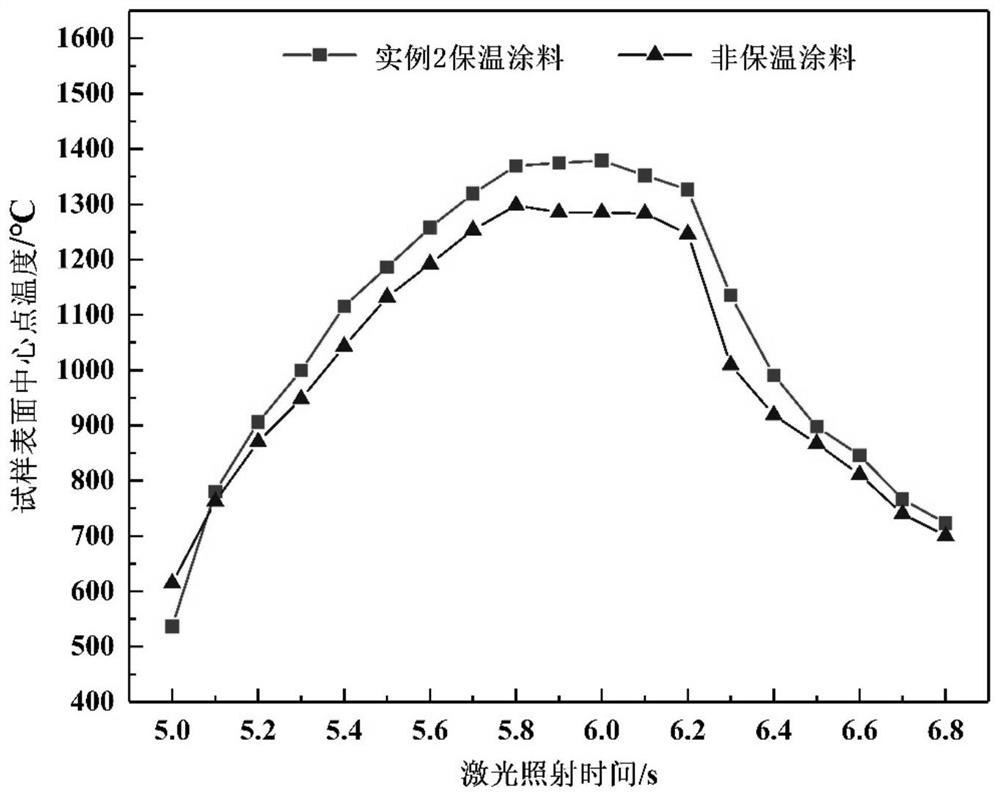

Embodiment 2

[0046] A laser quenching light-absorbing coating with thermal insulation function and a preparation method thereof, comprising the following steps:

[0047](1) Prepare a uniform heat-insulating light-absorbing coating:

[0048] S1: Pour 0.5 parts of zirconium dioxide, 10 parts of rare earth rhenium and 7 parts of carbon black into a ball mill for ball milling, with a particle size of more than 2000 mesh;

[0049] S2: Fully dissolve and stir 62 parts of benzene-free banana water and 20 parts of thermoplastic acrylic varnish;

[0050] S3: 0.5 parts of zirconium dioxide, 10 parts of rare earth rhenium and 7 parts of carbon black mixture after ball milling in step S1, 62 parts of benzene-free banana water and 20 parts of thermoplastic acrylic varnish auxiliary materials dissolved and stirred in step S2 are fully mixed and stirred;

[0051] S4: Pour 0.5 part of ethyl cellulose into the mixed material after stirring in S3 to fully mix and stir.

[0052] (2) Coating the above-menti...

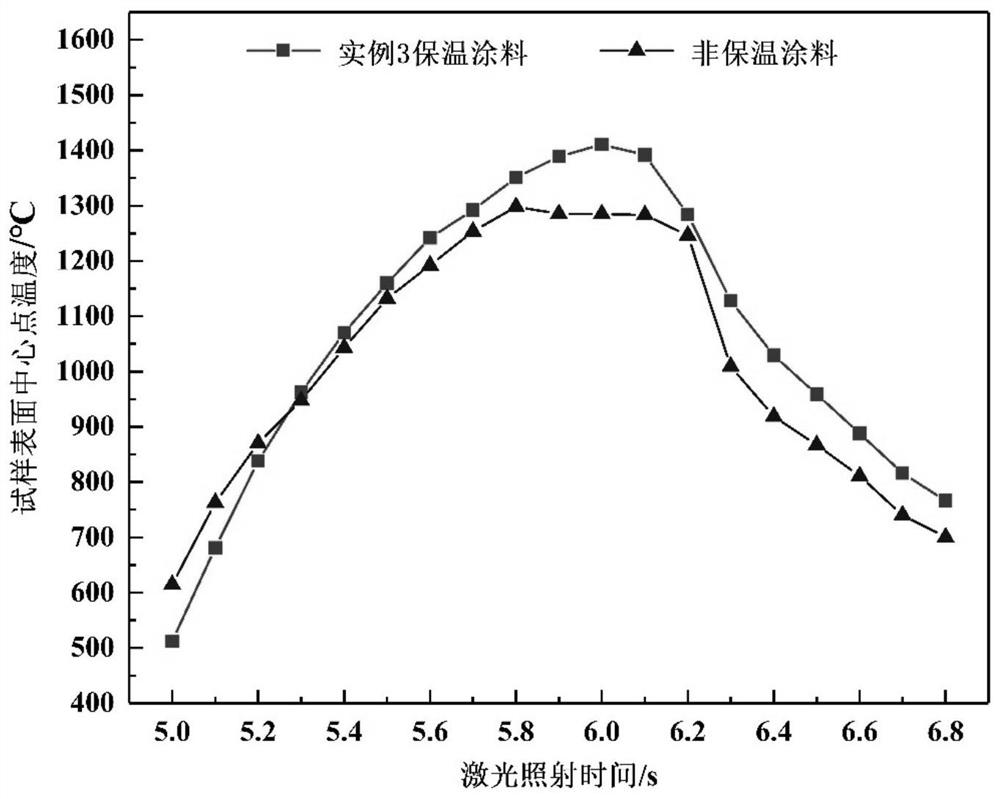

Embodiment 3

[0057] A laser quenching light-absorbing coating with thermal insulation function and a preparation method thereof, comprising the following steps:

[0058] (1) Prepare a uniform heat-insulating light-absorbing coating:

[0059] S1: Pour 1 part of zirconium dioxide, 9 parts of rare earth rhenium and 8 parts of carbon black into a ball mill for ball milling, with a particle size of more than 2000 mesh;

[0060] S2: Fully dissolve and stir 60 parts of benzene-free banana water and 21 parts of thermoplastic acrylic varnish;

[0061] S3: 1 part of zirconium dioxide, 9 parts of rare earth rhenium and 8 parts of carbon black mixture after ball milling in step S1, 60 parts of benzene-free banana water and 21 parts of thermoplastic acrylic varnish auxiliary materials dissolved and stirred in step S2 are fully mixed and stirred;

[0062] S4: Pour 1 part of ethyl cellulose into the mixed material after stirring in S3 to fully mix and stir.

[0063] (2) Coating the above-mentioned nove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com