Fluorescence detection method for content of bisphenol S

A fluorescence detection and content technology, applied in the field of chemical analysis and detection, can solve problems such as complex operation of bisphenol S

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A fluorescence detection method for the content of bisphenol S, the present embodiment is a fluorescence quenching system detection of bisphenol S, comprising the following steps:

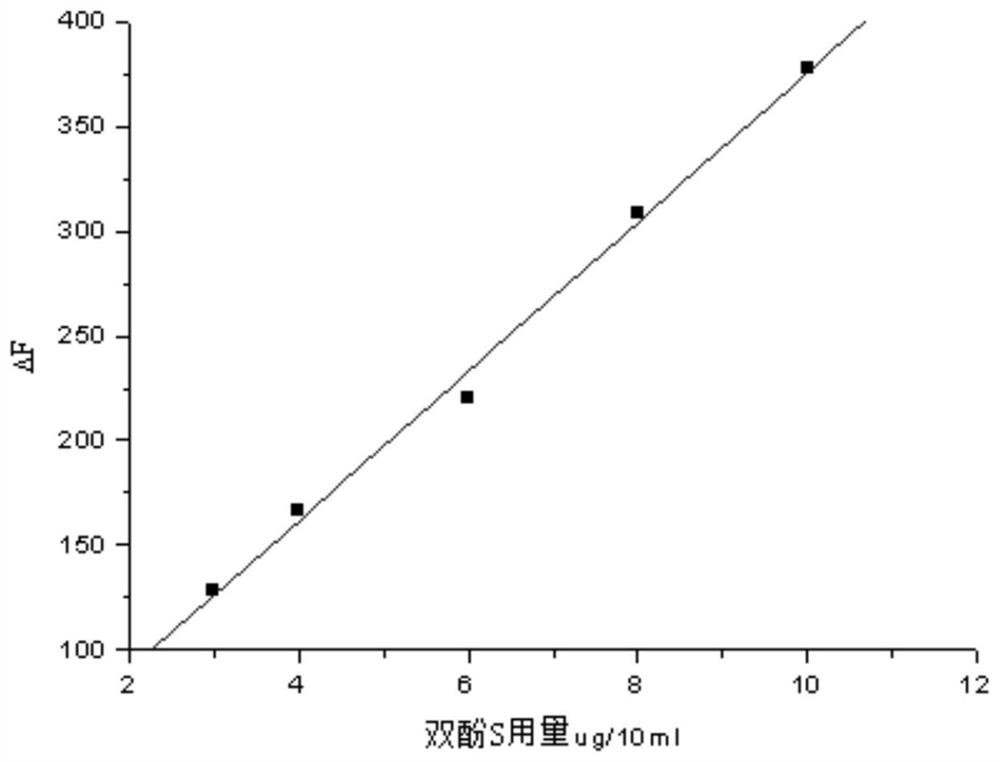

[0040] (1) Prepare a series of bisphenol S solutions with different standard concentrations: weigh 0.0425g of bisphenol S, add 5mL of absolute ethanol to dissolve, then transfer to a 100mL volumetric flask, add deionized water to the mark, shake well, Prepare a stock solution of 425 μg / mL, and then prepare a series of bisphenol S solutions with different standard concentrations: 0 μg / mL, 0.3 μg / mL, 0.4 μg / mL, 0.6 μg / mL, 0.8 μg / mL, 1 μg / mL.

[0041] (2) Drawing of bisphenol S standard curve:

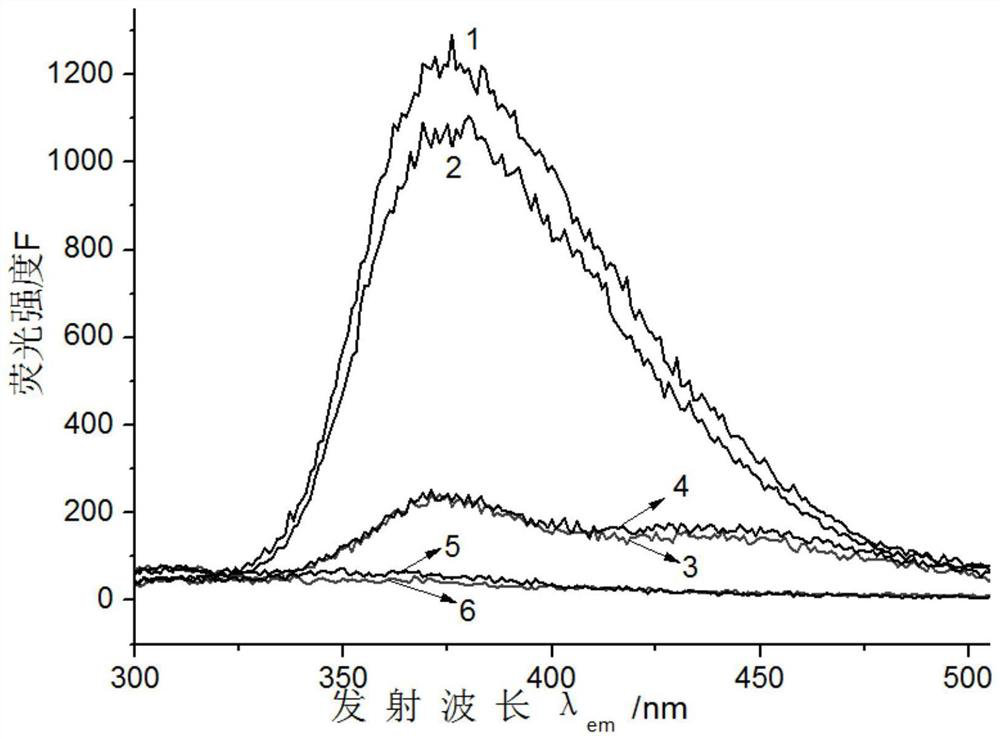

[0042] The fluorescence characteristics of each substance in the fluorescence quenching system are as follows: figure 1 As shown, where curve 1 represents acid fuchsin+CTMAB, curve 2 represents bisphenol S+acid fuchsin+CTMAB, curve 3 represents acid fuchsin, curve 4 represents acid fuchsin+bisphenol S,...

Embodiment 2

[0049] A fluorescence detection method for the content of bisphenol S, the present embodiment is a fluorescent sensitization system for detection of bisphenol S, comprising the following steps:

[0050] (1) Prepare a series of bisphenol S solutions with different standard concentrations: weigh 0.0100g bisphenol S, add 5mL ethanol to dissolve, transfer to a 50mL volumetric flask, add deionized water to the mark, shake well, and make 200μg / mL stock solution, and then prepare bisphenol S solutions with different standard concentrations.

[0051] (2) Drawing of bisphenol S standard curve:

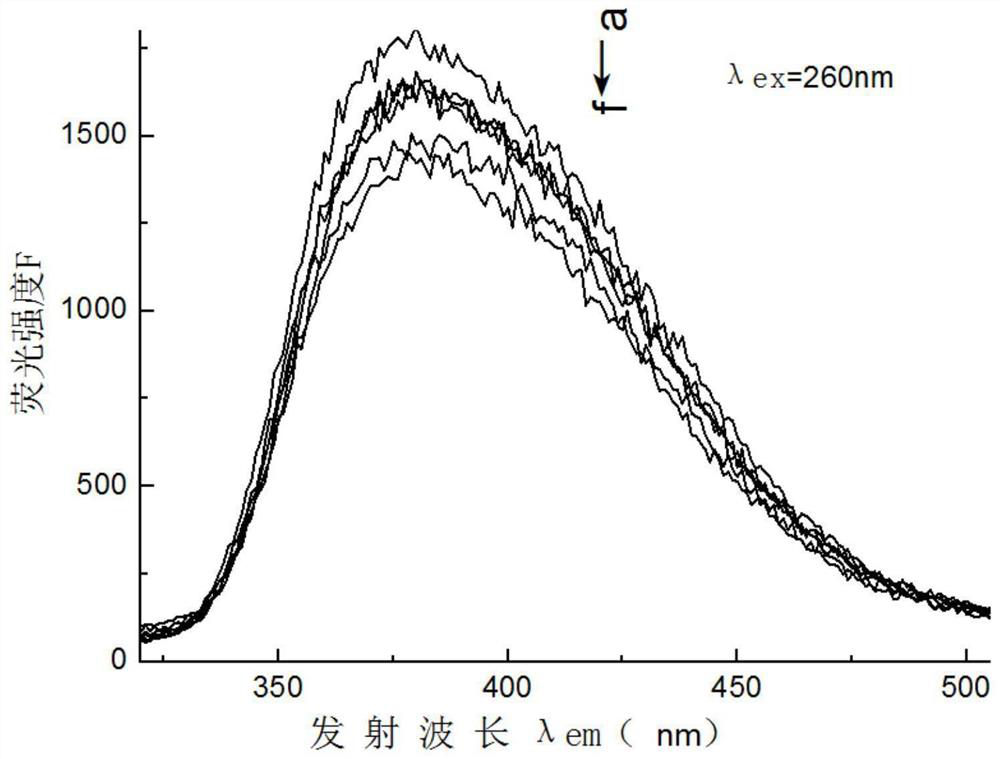

[0052] The fluorescence characteristics of each substance in the fluorescence sensitization system are as follows: Figure 4 As shown, where curve 1 represents bisphenol S, curve 2 represents CTMAB, curve 3 represents borax, curve 4 represents acid fuchsin + borax, curve 5 represents acid fuchsin, curve 6 represents acid fuchsin + borax + bisphenol S, Curve 7 represents acid fuchsin+CTMAB, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com