CuWO4/Bi2WO6 compound as well as preparation method and application thereof

A compound and hydrothermal reaction technology, applied in the field of environmental pollution restoration, can solve the problems of high cost of reverse osmosis, low removal efficiency of precipitation method, harsh environment requirements of biological method, etc., and achieve the effect of high degradation rate and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

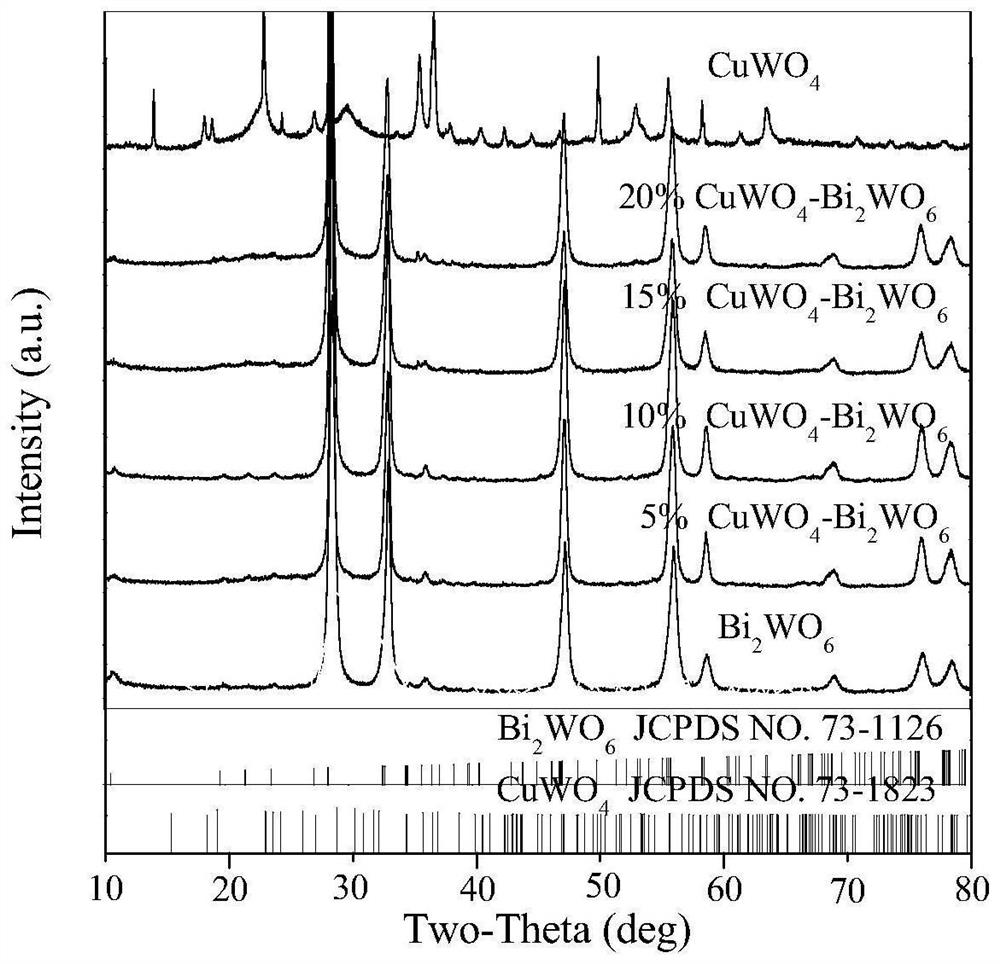

[0023] CuWO 4 / Bi 2 WO 6 The preparation method of compound comprises the following steps:

[0024] Step 1: Accurately weigh citric acid 0.192g, Bi(NO 3 ) 3 ·5H 2 O 0.970g, Na 2 WO 4 2H 2 0.330g, add 0.0121g, 0.0242g, 0.0363g, 0.0484g Cu (NO 3 ) 2 ·3H 2 0. Put it into a 250ml Erlenmeyer flask for later use, add 60mL of distilled water to the Erlenmeyer flask, stir magnetically for 30min, and then ultrasonicate for 30min (ultrasonic power 200W).

[0025] Step 2: Transfer the solution prepared in Step 1 to 100 ml of polytetrafluoroethylene, put it in an oven, and let it react at 180°C for 24 hours. After the reaction, cool to room temperature. The reactant in the reaction kettle was suction filtered to leave the filter residue, the filtrate was discarded, and then washed with water until the pH of the filtrate remained unchanged, and then washed 3 times with absolute ethanol, the filter residue was placed in a petri dish and then placed in an oven for When the temper...

Embodiment 2

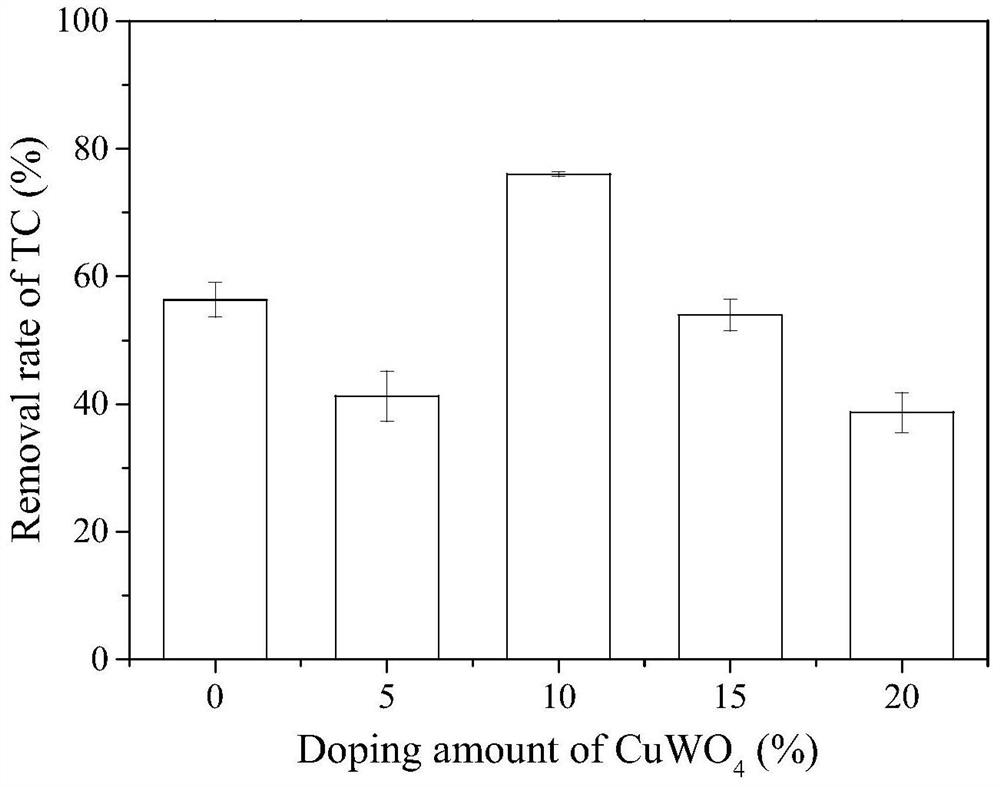

[0028] Comparison of CuWO with different composite ratios 4 / Bi 2 WO 6 Compound sonication effect of tetracycline:

[0029] Step 1: Take 20 mL of tetracycline solution with a concentration of 20 mg / L in a beaker, add 0.02 g of 5% CuWO 4 / Bi 2 WO 6 , 10% CuWO 4 / Bi 2 WO 6 , 15% CuWO 4 / Bi 2 WO 6 , 20% CuWO 4 / Bi 2 WO 6 . Under the condition of power of 500W, ultrasonic for 60min.

[0030] Step 2: After the suspension is sampled and centrifuged, the supernatant is taken to measure the concentration of tetracycline, and the CuWO is calculated 4 / Bi 2 WO 6 The sonication efficiency of tetracycline by composites, it can be seen that CuWO with composite ratios of 0%, 5%, 10%, 15% and 20% 4 / Bi 2 WO 6 The degradation rates of the complex to tetracycline were 56.32±2.71%, 41.22±3.92%, 76.00±0.38%, 53.93±2.48% and 38.69±3.12% (see image 3 ).

[0031] According to the degradation rate of tetracycline by the compound, the compound with a compound ratio of 10% has t...

Embodiment 3

[0033] Comparing different concentrations of potassium persulfate, CuWO with a compound ratio of 10% 4 / Bi 2 WO 6 Steps in which the complex degrades the effects of tetracyclines:

[0034] Step 1: Take 20 mL of tetracycline solution with a concentration of 20 mg / L in a beaker, and add 20 mg of CuWO with a compounding ratio of 10% accurately weighed 4 / Bi 2 WO 6 For the composite, add potassium persulfate so that the concentration of potassium persulfate in the waste water is 0, 1, 2, 5, 10 mmol / L and sonicate for 60 min respectively.

[0035] Step 2: After the suspension is sampled and centrifuged, the supernatant is taken to measure the concentration of tetracycline, and the CuWO is calculated 4 / Bi 2 WO 6 Tetracycline degradation efficiency of the compound, it can be seen that the concentration of potassium persulfate is 0, 1, 2, 5, 10mmol / L, and the degradation rate of the compound to tetracycline is 76.00±0.38%, 80.60±0.75%, 83.66±0.91%, 86.86 ±0.24%, 98.32±0.39%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com