Multilayer polymer foam material and preparation method thereof

A foaming material and polymer technology, applied in the field of multi-layer polymer foaming materials and their preparation, can solve the problems of high expansion ratio, layer-to-layer separation, interlayer bubbles, etc., and achieve good mechanical properties and large expansion ratio. , the effect of the simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of multilayer polymer foam material provided by the invention comprises:

[0026] S1, providing a first polymer and nanoparticles, mixing the first polymer and the nanoparticles to obtain a mixture;

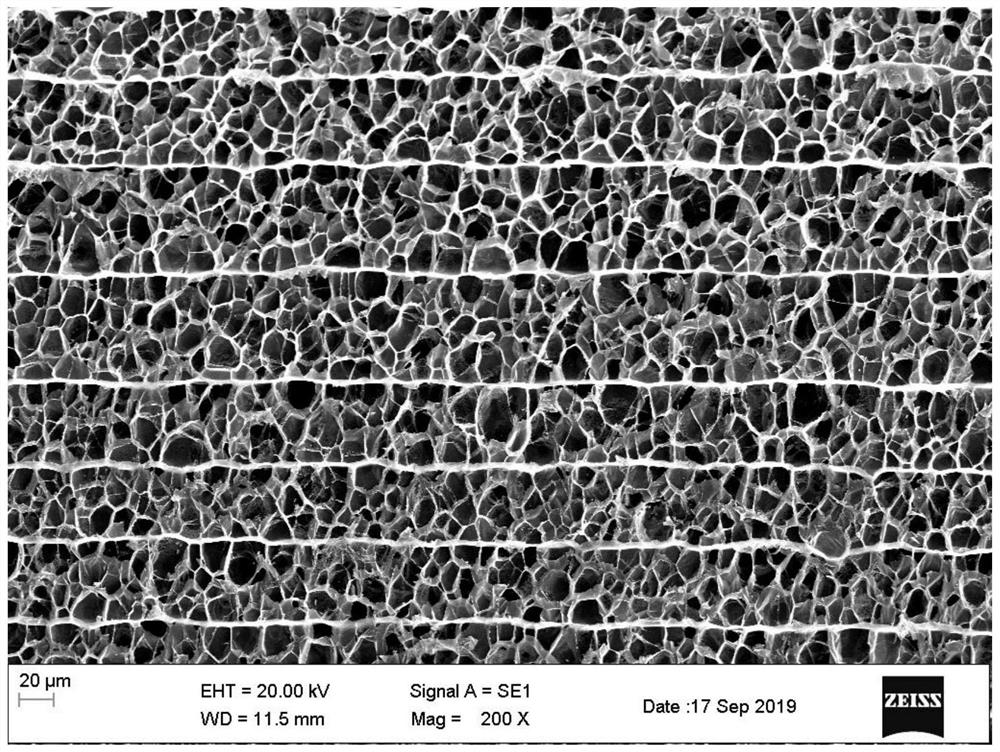

[0027] S2, providing a second polymer, and forming the second polymer and the mixture into a sheet structure through a multilayer co-extrusion method, wherein the sheet structure includes at least one second polymer layer and at least one hybrid layer, and the second polymer is a polymer of the same monomer as the first polymer;

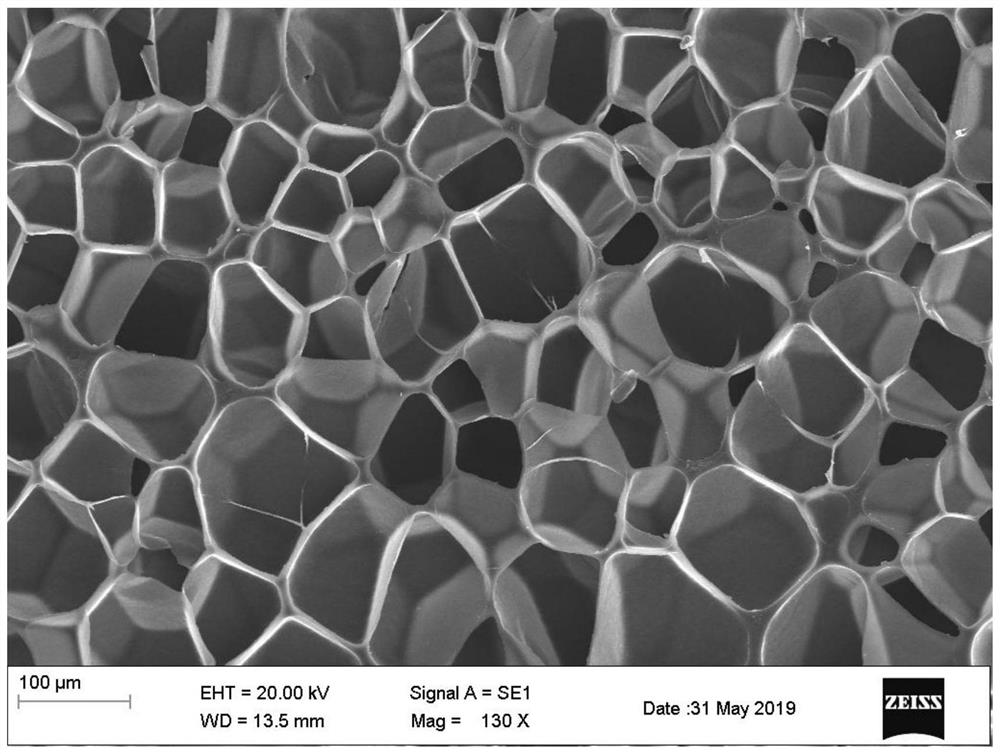

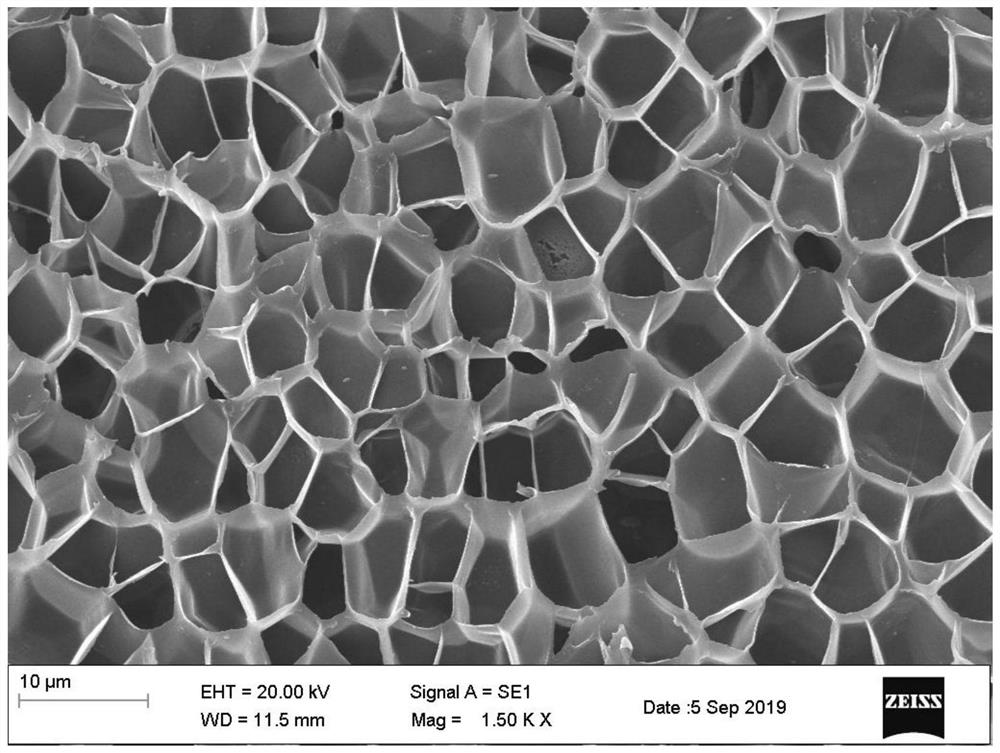

[0028] S3, foaming the sheet structure, foaming the mixed layer in the sheet structure to form a foam layer, to obtain a multilayer polymer comprising at least one film layer and at least one foam layer foaming material.

[0029] In step S1, the first polymer includes one of polypropylene, polyethylene, polystyrene, polymethyl methacrylate, polylactic acid, polyolefin elastomer, and polycarbonate.

[0030] The nanopartic...

Embodiment 1

[0065] Blending the nano-silica and the first polystyrene to obtain a mixture, wherein the mass percentage of the nano-silica is 0.1 wt%.

[0066] The second polystyrene and the mixture are made into a sheet with a width of 5 cm, a thickness of about 1 mm, and 128 layers through a multi-layer co-extrusion device. The thickness of the polystyrene layer in the sheet is 5.5 μm, and the thickness of the mixed layer is The thickness is 10.1 μm, and the polystyrene layer and the mixed layer are alternately stacked and distributed, and the melt index difference between the second polystyrene and the first polystyrene is 4.5.

[0067] Put the sheet in an autoclave for saturation, the saturated gas is carbon dioxide, the saturation pressure is 2MPa, the saturation time is 72h, and the temperature of the autoclave is 25°C. After the saturation is completed, the sheet that has reached the saturation pressure is taken out and placed in Foaming is carried out in simethicone oil at a temper...

Embodiment 2

[0069] Blending the nano-calcium carbonate and the first polypropylene to obtain a mixture, wherein the mass percentage of the nano-calcium carbonate is 1 wt%.

[0070] The second polypropylene and the mixture are made into a sheet with a width of 10 cm, a thickness of 2 mm, and 32 layers through a multilayer co-extrusion device. The thickness of the polypropylene layer in the sheet is 10 μm, and the thickness of the mixed layer is 115 μm. And the polypropylene layer and the mixed layer are alternately stacked and distributed, and the difference between the melt indices of the first polypropylene and the second polypropylene is zero.

[0071] Put the sheet in an autoclave for saturation, the saturated gas is carbon dioxide, the saturation pressure is 5MPa, the saturation time is 24h, and the temperature of the autoclave is 25°C. After the saturation is completed, the sheet that has reached the saturation pressure is taken out and placed in Foaming was carried out in glycerin a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com