Method for preparing hexagonal flaky flame-retardant magnesium hydroxide from natural hydromagnesite

A technology of hexagonal flakes and magnesium hydroxide, applied in the direction of magnesium hydroxide, can solve the problems of cumbersome methods, high cost, unfriendly environment, etc., and achieve the effect of reasonable technical route, low production cost and high industrial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

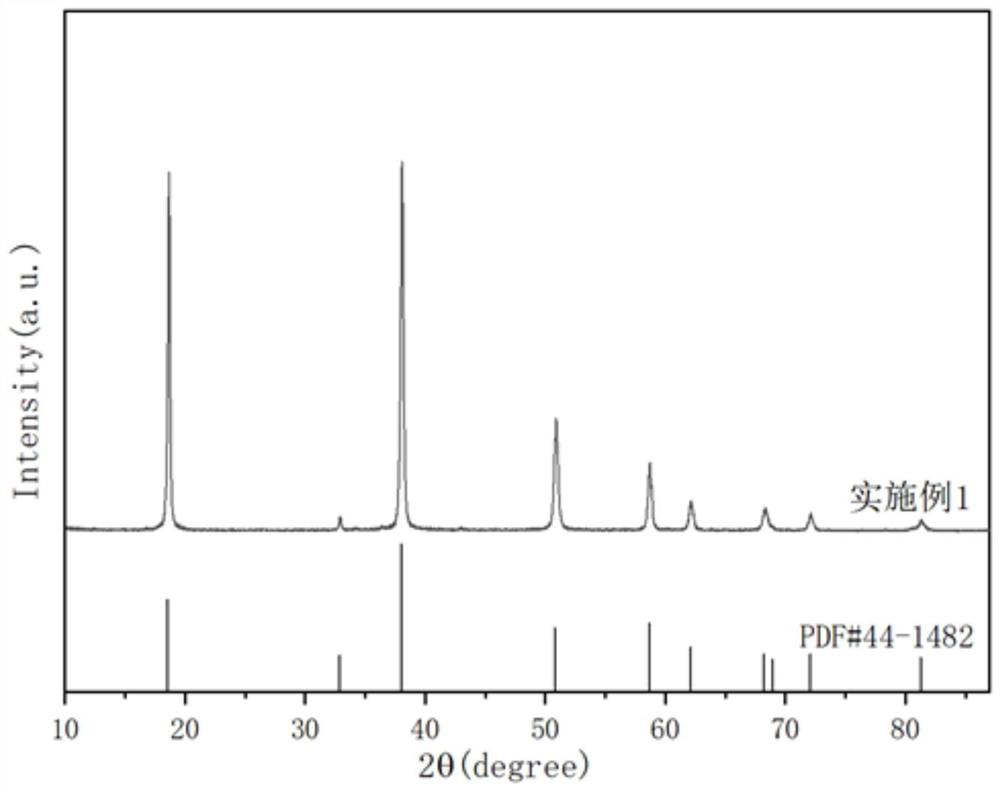

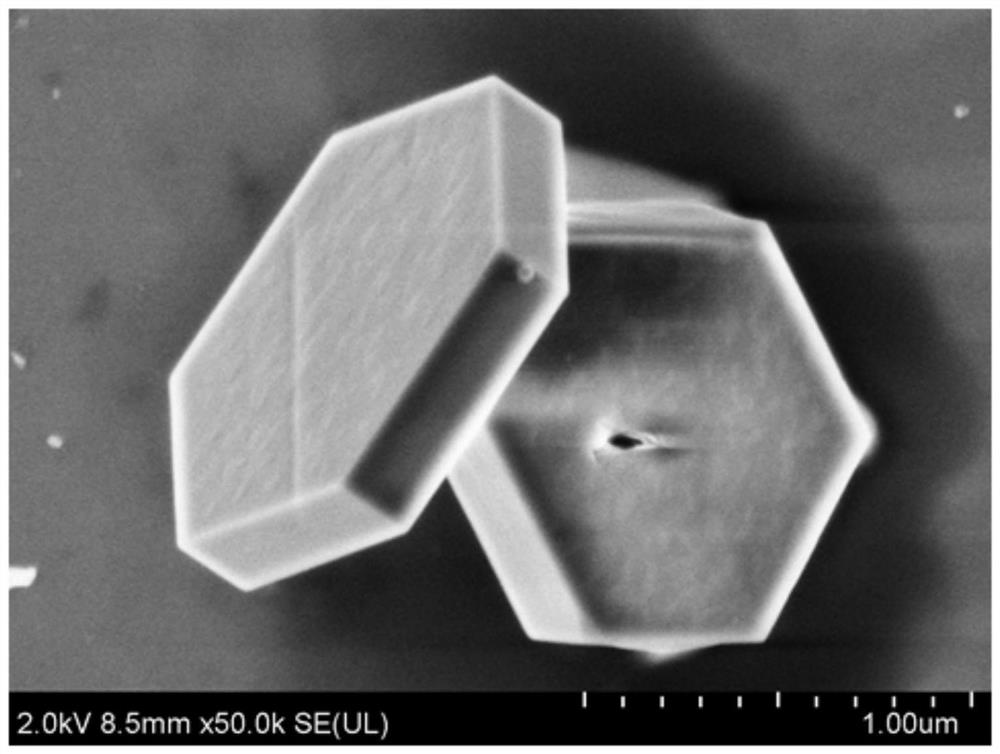

[0042] The natural hydromagnesite is crushed and sieved, and the sieved hydromagnesite is weighed and calcined at 600°C for 2 hours, the heating rate is 10°C / min, and the activated magnesium oxide obtained after the hydromagnesite is completely decomposed is sieved, Using activated magnesia as the raw material and deionized water as the solvent, ultrasonically disperse for 15 minutes to prepare a magnesia suspension with a slurry concentration of 10%. Put the magnesia suspension into a closed heating device and heat it at a constant temperature of 140°C After 4 hours, the stirring speed was 300 rpm. After the reaction was completed, the product was naturally cooled to room temperature, and the product was filtered, washed and dried to obtain hexagonal flaky magnesium hydroxide. Product 1 was obtained. Product XRD and SEM pictures such as figure 1 , 2 shown.

[0043] Compared with the magnesium hydroxide crystal PDF standard card, it can be seen that the product has high pur...

Embodiment 2

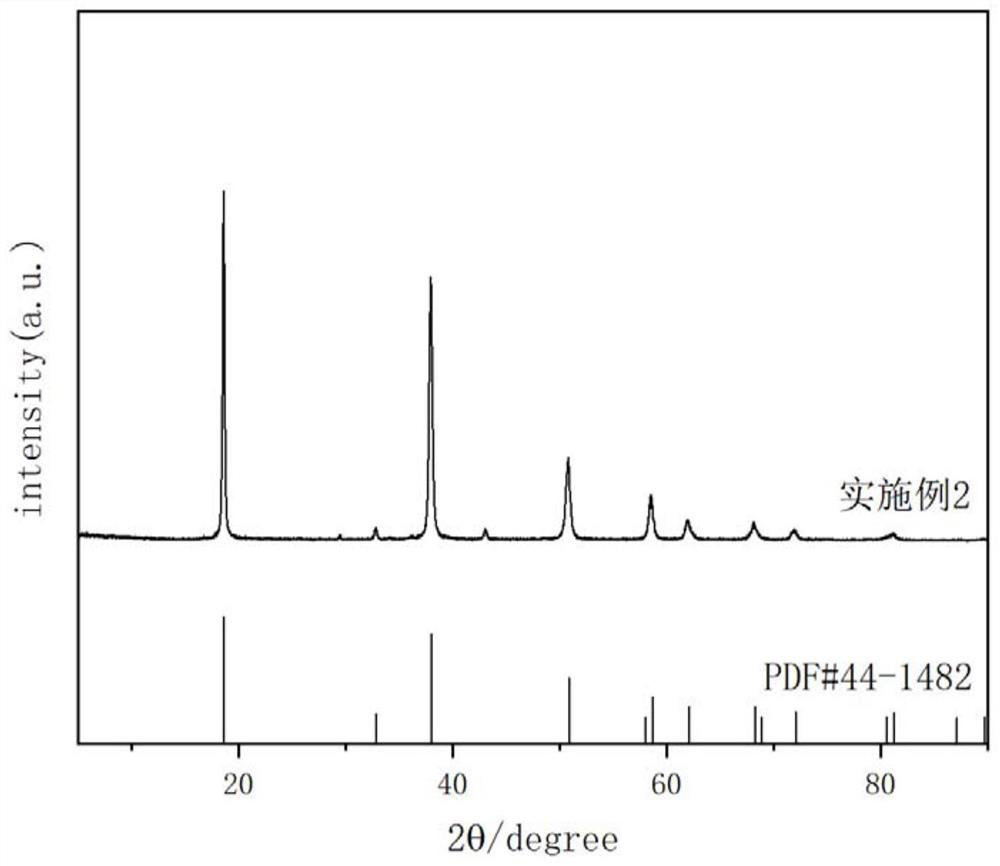

[0045] The natural hydromagnesite is crushed and sieved, and the sieved hydromagnesite is weighed and calcined at 800°C for 2 hours, the heating rate is 10°C / min, and the activated magnesium oxide obtained after the hydromagnesite is completely decomposed is sieved, Using activated magnesia as raw material and deionized water as solvent, ultrasonically disperse for 15 minutes to prepare a magnesia suspension with a slurry concentration of 10%. Put the magnesia suspension into a closed heating device and heat it at a constant temperature of 160°C After 4 hours, the stirring speed was 300 rpm. After the reaction was completed, the product was naturally cooled to room temperature, and the product was filtered, washed and dried to obtain hexagonal flaky magnesium hydroxide. Product 2 was obtained. Product XRD and SEM pictures such as image 3 , 4 shown.

[0046] Compared with the magnesium hydroxide crystal PDF standard card, it can be seen that the product has a high purity. F...

Embodiment 3

[0048] The natural hydromagnesite is crushed and sieved, and the sieved hydromagnesite is weighed and calcined at 800°C for 2 hours, the heating rate is 10°C / min, and the activated magnesium oxide obtained after the hydromagnesite is completely decomposed is sieved, Using activated magnesia as raw material and deionized water as solvent, ultrasonically disperse for 15 minutes to make a magnesia suspension with a slurry concentration of 10%, put the magnesia suspension into a closed heating device, and heat it at a constant temperature of 180°C After 4 hours, the stirring speed was 300 rpm. After the reaction was completed, the product was naturally cooled to room temperature, and the product was filtered, washed and dried to obtain hexagonal flaky magnesium hydroxide. Product 3 was obtained. Product XRD and SEM pictures such as Figure 5 , 6 shown.

[0049] Compared with the magnesium hydroxide crystal PDF standard card, it can be seen that the product has high purity. From...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com