Process for removing COD (Chemical Oxygen Demand) in high-salinity wastewater

A high-salt wastewater, process technology, applied in water pollutants, water/sewage treatment, water/sewage multi-stage treatment, etc. Reduce business costs and achieve the effect of waste recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

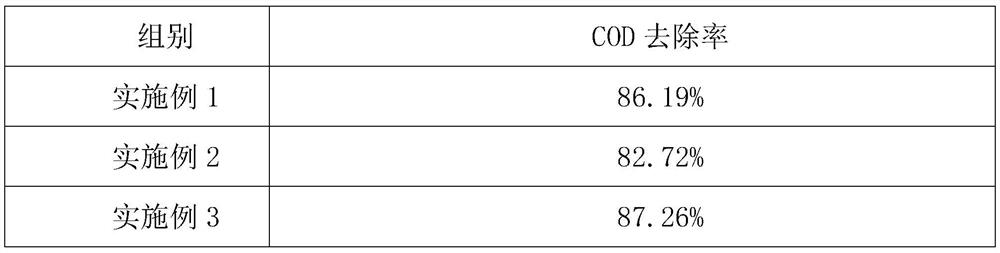

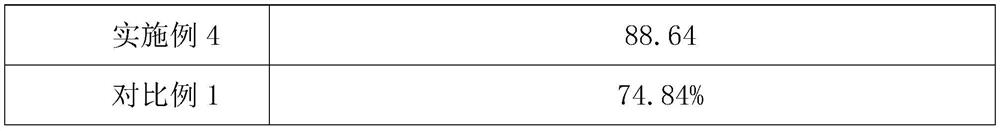

Examples

Embodiment 1

[0034] This embodiment discloses a COD removal process in high-salt wastewater, comprising the following steps:

[0035] (1) PH adjustment: transfer the high-salt wastewater to the pH adjustment tank with stirring, add acid (hydrochloric acid or sulfuric acid) while stirring the high-salt wastewater, and adjust the pH of the wastewater to 3-4.

[0036] (2) Oxidation treatment: The effluent from step (1) is fed into the Fenton oxidation tank by the lift pump, and H is added to the Fenton oxidation tank. 2 o 2 and ferrous sulfate and stir well, H 2 o 2 The mass ratio of COD to high-salt wastewater is 5:1, and H 2 o 2 with Fe in ferrous sulfate 2+ The molar ratio is 3:1.

[0037] (3) Active adsorption: step (2) the effluent flows into the activated carbon adsorption pool by itself, and the powdered activated carbon of the corresponding quality is added according to 3 to 6 times the COD mass concentration and fully stirred, and the adsorption treatment is 45-60min;

[0038]...

Embodiment 2

[0046] The process for removing COD in a kind of high-salt wastewater disclosed in this embodiment is basically the same as the process in Example 1, the only difference is: in step (2), H 2 o 2 The mass ratio of COD to high-salt wastewater is 6:1, and H 2 o 2 with Fe in ferrous sulfate 2+ The molar ratio is 6:1.

Embodiment 3

[0048] The process for removing COD in a high-salt wastewater disclosed in this example is basically the same as the process in Example 1, except that the raw materials of powdered activated carbon include: 40 parts of activated sludge and 15 parts of sodium hydroxide in parts by weight. , 8 parts of sodium carbonate, 20 parts of gelatin, 4 parts of potassium bicarbonate, and the rest is deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com