Corrosion inhibitor for preventing surface of hot-rolled pickled steel from blackening and preparation method of corrosion inhibitor

A hot-rolled pickling and surface blackening technology, applied in the field of metal surface treatment, can solve problems such as the adverse effects of subsequent processing and use, the problem of blackening is not significantly improved, and the market competitiveness of products is reduced, so as to reduce grain boundary corrosion. , Improve the effect of blackening and reducing iron loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

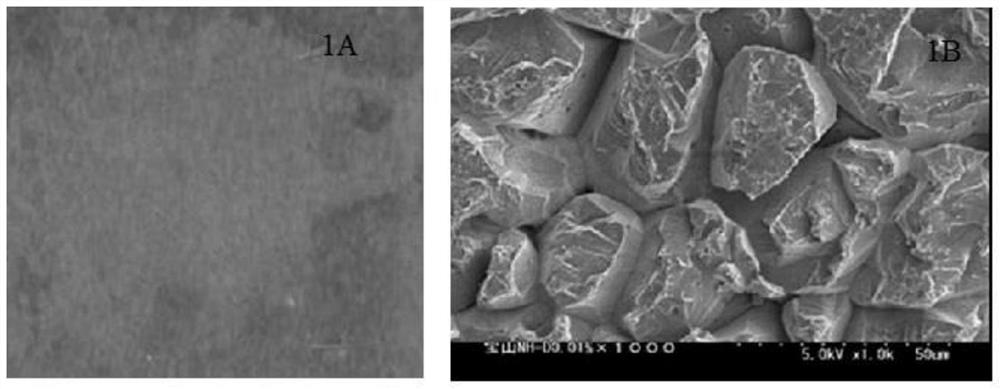

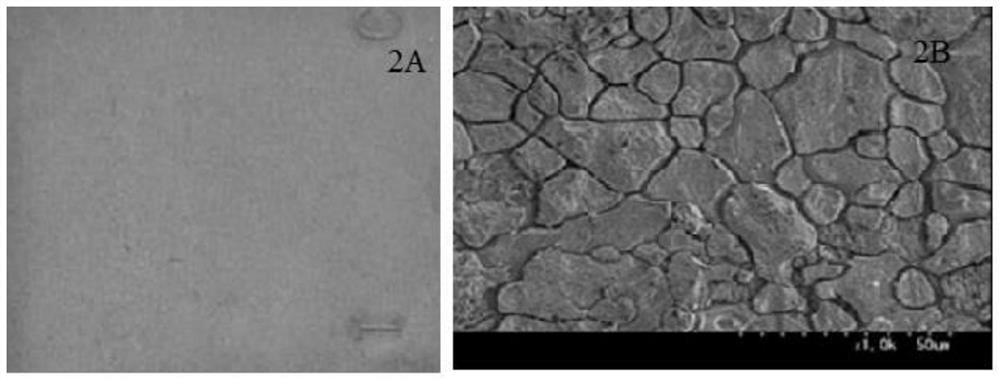

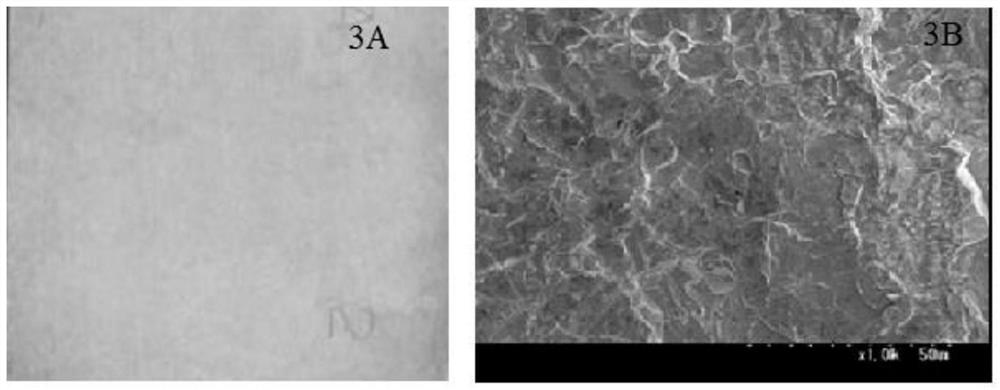

Image

Examples

Embodiment 1

[0031] Add 3-anilino-1-phenylacetone and rosin glycidyl ethanolamine to the flask, mix evenly, add acid, control the dropping rate to 2-3 drops / s, react at 158°C for 2 hours, and condensation reaction occurs to form an intermediate , then add polyoxyethylene nonylphenyl ether, then stir at normal temperature, the reaction time is 3 hours, the molar ratio of the 3-anilino-1-phenylacetone and rosin glycidyl ethanolamine is 1:1, the intermediate The molar ratio to polyoxyethylene nonylphenyl ether is 1:1, and finally the corrosion inhibitor is obtained after distilling off the solvent with a yield of 90.2%.

Embodiment 2

[0033] Compared with Example 1, the molar ratio of 3-anilino-1-phenylacetone and rosin glycidyl ethanolamine is 1:1.2, and the others are kept the same, and the yield is 91.3%.

Embodiment 3

[0035] Compared with Example 1, the molar ratio of 3-anilino-1-phenylacetone and rosin glycidyl ethanolamine is 1:1.5, and the others are kept the same, and the yield is 90.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com