Photodynamic nano antibacterial material as well as preparation method and application thereof

A nano-antibacterial material and photodynamic technology, applied in antibacterial drugs, nanotechnology, nano-optics and other directions, can solve the problems of inability to ensure the stability of composite materials, inability to meet broad-spectrum antibacterial requirements, and inability of materials to exert antibacterial effects. The effect of aggravating oxidative damage, shortening the action distance, and enhancing the antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

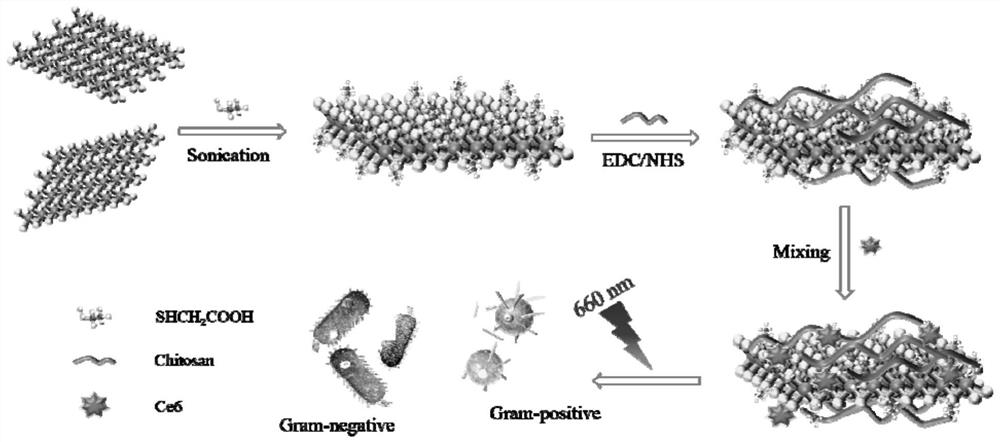

[0039] A kind of M-CS-Ce6 photodynamic nano antibacterial material, its preparation comprises the steps:

[0040] 50mg MoS 2 Disperse in 25 mL of ultrapure water, sonicate at 20 °C for 6 h, add thioglycolic acid in a volume of 200 μL to the above MoS 2 In the dispersion, sonicate at 25 °C for 24 h to realize the mercapto group in MoS 2 surface modification. Then 65 mg of chitosan was added to the mixture and ultrasonicated for 20 min to form a homogeneous colloidal suspension.

[0041] 150mg EDC and 65mg NHS were gradually added to the mixture, ultrasonicated at 25°C for 15min, stirred at 600rpm at 25°C for 1h to activate the carboxyl group for amide reaction,

[0042] Then the reaction mixture was transferred to a dialysis bag (8 ~ 14KDa), respectively with 10mM acetic acid (1.5 × 10 3 mL) dialyzed for 2 days, ultrapure water (1.5×10 3 mL) was dialyzed for 2 days. Dilute the mixture in 1.2×10 4 Centrifuge at rpm for 30 min, freeze-dry in vacuum at -60°C for 48 h to obt...

Embodiment 2

[0045] A kind of M-CS-Ce6 photodynamic nanometer material, its preparation comprises the steps:

[0046] 35mg MoS 2 Disperse in 25 mL ultrapure water, sonicate at 25 °C for 5 h, add 250 μL volume of thioglycolic acid to MoS 2 In the dispersion, sonicate at 20°C for 20 h to realize the sulfhydryl group in MoS 2 surface modification. Then 70 mg of chitosan was added to the mixture and ultrasonicated for 15 min to form a homogeneous colloidal suspension.

[0047] 70mg EDC and 55mg NHS were gradually added to the mixture, ultrasonicated at 20°C for 12min, and stirred at 660rpm for 50min at 20°C to activate the carboxyl group for amide reaction.

[0048] Afterwards, the reaction mixture was transferred to a dialysis bag (8 ~ 14KDa), and 5mM acetic acid (1.2×10 3 mL) dialyzed for 1.4 days, ultrapure water (1.2×10 3 mL) was dialyzed for 1.4 days. Dilute the mixture at 1.0×10 4 Centrifuge at rpm for 20 min, freeze-dry in vacuum at -70°C for 32 h to obtain M-CS powder, then add ...

Embodiment 3

[0051] A kind of M-CS-Ce6 photodynamic nanometer material, its preparation comprises the steps:

[0052] 25mg MoS 2 Dispersed in 25 mL of ultrapure water, sonicated for 4 h at 22 °C, 167 μL volume of thioglycolic acid was added to the above MoS 2 In the dispersion liquid, sonicate at 22°C for 16h to achieve the 2 surface modification. Then 25 mg of chitosan was added to the mixture and ultrasonicated for 10 min to form a homogeneous colloidal suspension.

[0053] Gradually add 60mg EDC and 25mg NHS to the mixture, sonicate at 22°C for 10min, stir and react at 800rpm for 40min at 22°C to activate the carboxyl group,

[0054] Then the reaction mixture was transferred to a dialysis bag (8 ~ 14KDa), respectively with 5mM acetic acid (1.0 × 10 3 mL) dialyzed for 1 day, ultrapure water (1.0×10 3 mL) was dialyzed for 1 day. Dilute the mixture to 1.1×10 4 Centrifuge at rpm for 15 min, freeze-dry in vacuum at -65°C for 24 h to obtain M-CS powder, then add water and ultrasonicall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com