Two-component water-based anticorrosive paint as well as preparation method and application thereof

An anti-corrosion coating, two-component technology, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as sagging, and achieve the effect of solving thick coating sagging, avoiding production safety and construction environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] A two-component water-based anti-corrosion coating, comprising the preparation raw materials of mass parts as described in the following table:

[0080] Table 1. The composition of raw materials for the preparation of two-component water-based anticorrosion coatings

[0081]

[0082]

[0083] The preparation method of two-component water-based anticorrosion coating comprises the steps:

[0084] (1) Pre-disperse and stir all the deionized water, dispersant, defoamer, anti-sedimentation thixotropic agent and all pigments and fillers evenly, and move to a sand mill to grind to obtain a water-based color paste with a fineness of ≤35 μm.

[0085] (2) Add water-based epoxy dispersion resin into the stirring tank, then add wetting agent, leveling agent, anti-flash corrosion agent, adhesion enhancer in turn under stirring conditions, and finally add the water-based color paste of step (1) , after stirring evenly, obtain the first component by filtering with a 100-mesh fi...

Embodiment 2

[0088] A two-component water-based anti-corrosion coating, comprising the preparation raw materials of mass parts as described in the following table:

[0089] Table 2. The composition of raw materials for the preparation of two-component water-based anti-corrosion coatings

[0090]

[0091]

[0092] The preparation method of the two-component water-based anti-corrosion coating of this embodiment is the same as that of Embodiment 1.

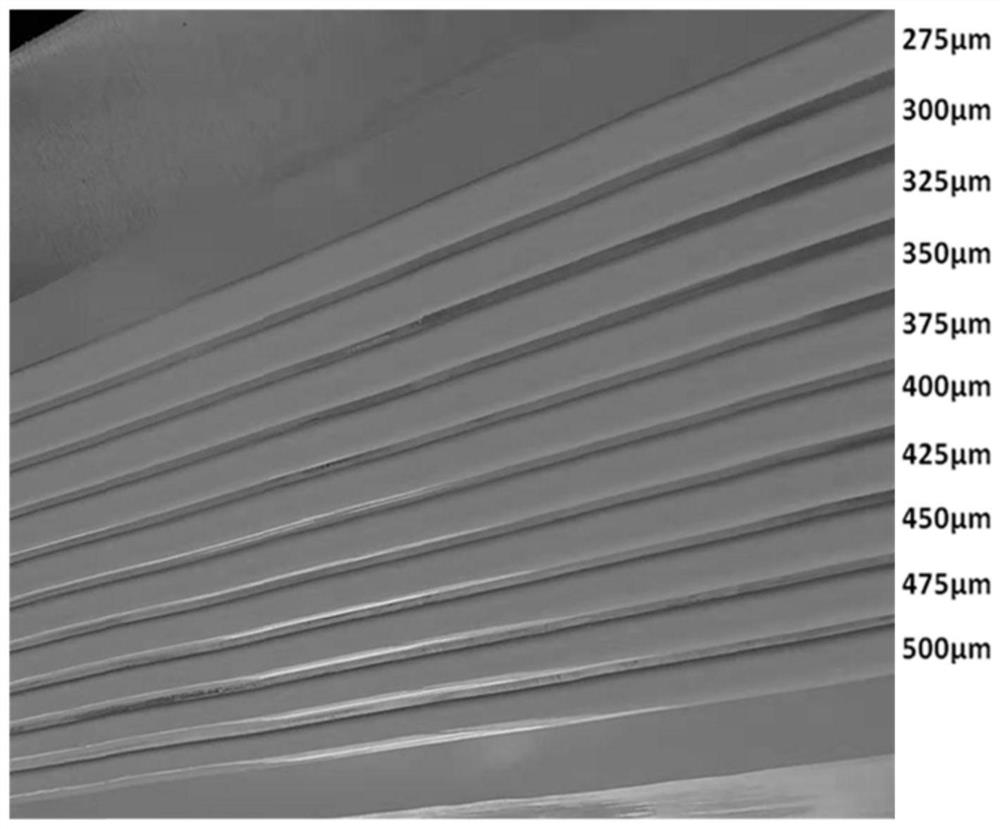

[0093] The viscosity of component A and component B of the two-component water-based anti-corrosion coating and the viscosity after the two components are mixed in proportion is tested, and the high-pressure plunger pump is used to supply the paint 2K automatic deployment spraying system (such as figure 1 , figure 1 The main agent pump is used for feeding component A, the pump for component B is used for feeding component B, and the cleaning pump is used for cleaning the spraying system) for one-time coating on the surface of aluminum subs...

Embodiment 3

[0101]Water-based epoxy dispersion resins with different epoxy equivalents are used to make two-component water-based anti-corrosion coatings, and a high-pressure plunger pump is used to supply paint with a 2K automatic deployment spraying system for one-time coating on the surface of carbon steel substrates, and baking (45 ° C) ×40min), the performance of the paint film was tested, and the results are shown in Table 4 below.

[0102] Table 4. Effect of different waterborne epoxy dispersion resins on the paint film

[0103]

[0104] In Table 4, the main difference between serial numbers 1 to 5 is that the water-based epoxy dispersion resins are different, and the specific raw material compositions are as follows:

[0105] Serial number 1:

[0106] Component A: water-based epoxy dispersion resin 6520: 42 parts, dispersant Tego757w: 1.5 parts, environmental protection anti-rust pigment zinc orthophosphate ZMP: 10 parts, iron oxide red 190: 10 parts, barium sulfate: 18 parts;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com