In-vitro synthesis and purification integrated preparation method for protein, kit and application thereof

An in vitro synthesis and protein synthesis technology, applied in the field of protein synthesis and in vitro protein synthesis, can solve the problems of reduced binding performance of purification media, large labor and time, and reduced purification effect, so as to shorten the preparation cycle, increase efficiency, and reduce retention Effect of Time and Retention Ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0317] The integrated protein synthesis and purification method in vitro at least includes the following steps:

[0318] Step i: At least provide an in vitro protein synthesis system, a nucleic acid template encoding the target protein, and a protein immobilization system, and place them in the same reaction vessel to form a reaction purification mixed system (intePure system or coPure system);

[0319] Wherein, the in vitro protein synthesis system can provide translation-related elements required for synthesizing the target protein together with the nucleic acid template encoding the target protein; the target protein can specifically bind to the protein immobilizing system (protein immobilizing system, PIS )superior;

[0320] Step ii: perform an incubation reaction under appropriate conditions to obtain a target protein product; during the incubation reaction, that is, during the in vitro protein synthesis reaction, the target protein product can specifically bind to the pr...

Embodiment 1

[0884] Embodiment 1. prepares the magnetic microsphere C of acrylic polymer modification

[0885] First, measure the aqueous solution of ferroferric oxide magnetic microspheres (the particle diameter of magnetic microsphere is about 1 μm) that 50mL silicon dioxide wraps, its solid content 20% (v / v), settle magnetic microsphere with magnet, remove For the liquid phase, the magnetic microspheres were washed with 60 mL of absolute ethanol each time, for a total of 5 times. Add 100 mL of an excess of 3-aminopropyltriethoxysilane (APTES, CAS: 919-30-2) in ethanol (25%, v / v) to the above-mentioned washed magnetic microspheres, at 50 ° C Stir mechanically in a water bath for 48 hours, then mechanically stir in a water bath at 70°C for 2 hours, settle the magnetic microspheres with a magnet, remove the liquid phase, wash the magnetic microspheres with 60 mL of absolute ethanol each time, wash twice in total, and then wash each time with The magnetic microspheres were washed with 60 m...

Embodiment 2

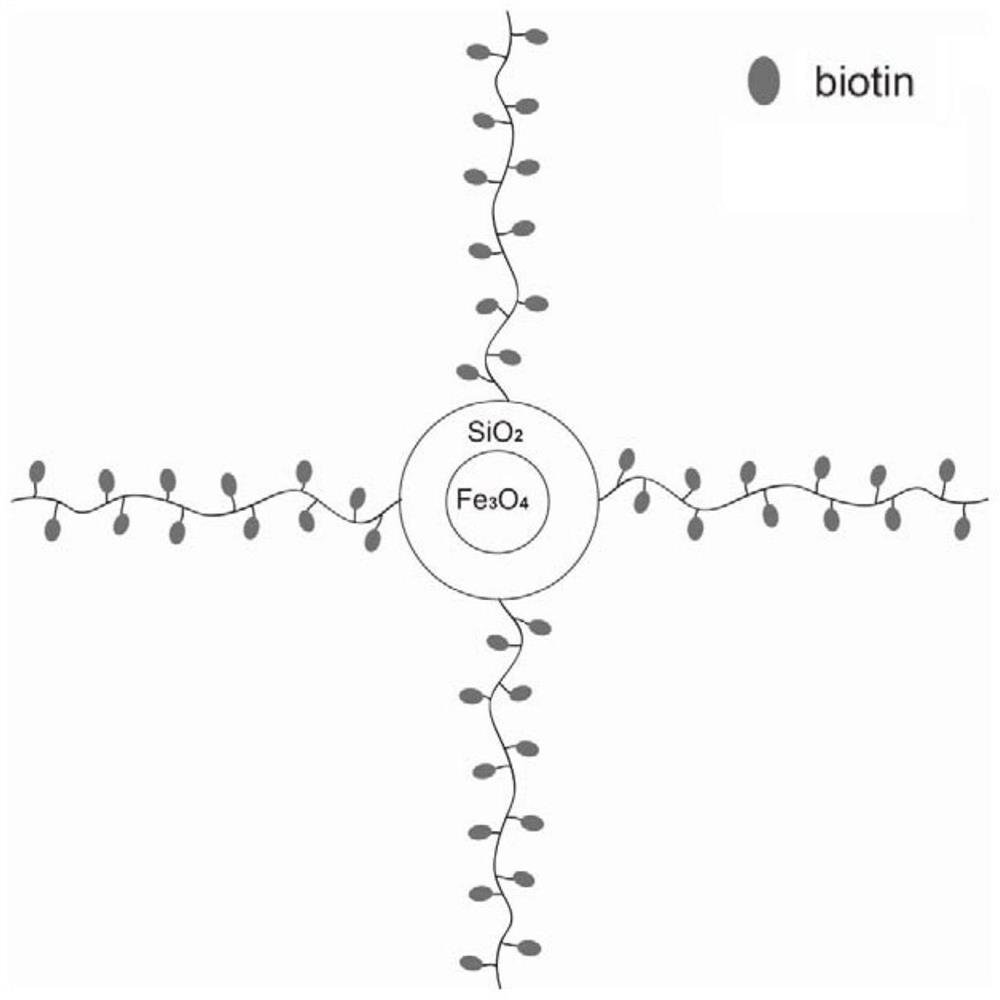

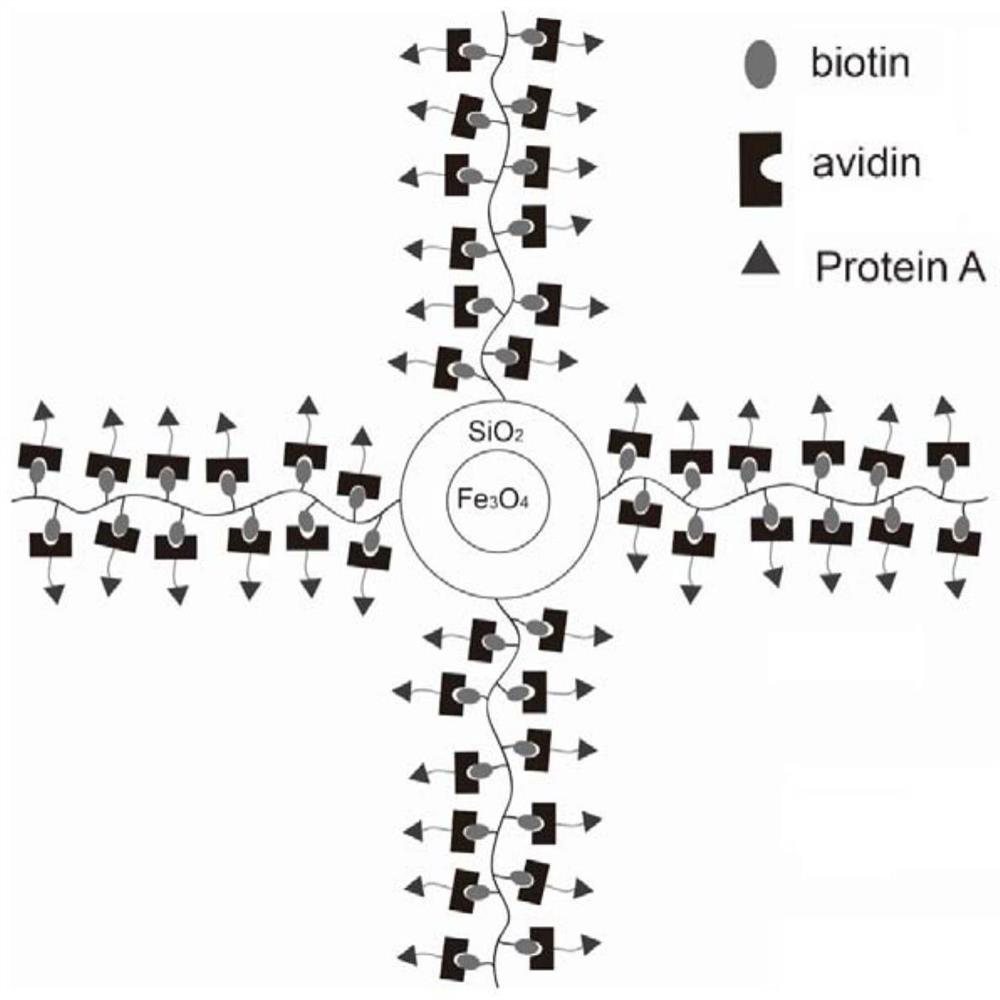

[0888] Example 2. Preparation of biotin-modified biomagnetic microspheres D

[0889] Transfer the synthesized magnetic microspheres C to 10mL solution X, add 0.004mol 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and 0.004mol N-hydroxysuccinyl amine, stirred and mixed at room temperature, stirred and reacted for 15min, settled the magnetic microspheres with a magnet, removed the liquid phase, and washed 3 times with 10mL distilled water each time; pipette 4.0×10 -4 mol 1,3-propanediamine, dissolved in 10mL PBS buffer solution, added to the washed magnetic microspheres, mechanically stirred in a water bath at 30°C for 20 hours, settled the magnetic microspheres with a magnet, and removed the liquid phase, each time Wash 6 times with 10mL distilled water, add 10mL PBS buffer solution; weigh 2.5×10 -4 mol biotin, add 10mL solution X, then add 1.0×10 -3 mol 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and 0.001mol N-hydroxysuccinimide, stirred and mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter size | aaaaa | aaaaa |

| Diameter size | aaaaa | aaaaa |

| Diameter size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com