Corrosion-resistant titanium alloy and preparation method thereof

A titanium alloy and corrosion-resistant technology, applied in the field of corrosion-resistant titanium alloy and its preparation, can solve the problems that the corrosion performance of titanium alloy is difficult to meet the engineering application, the service environment is harsh, etc., and achieves low cost, excellent corrosion resistance, and high resistance to corrosion. Corrosion Ability Increase Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

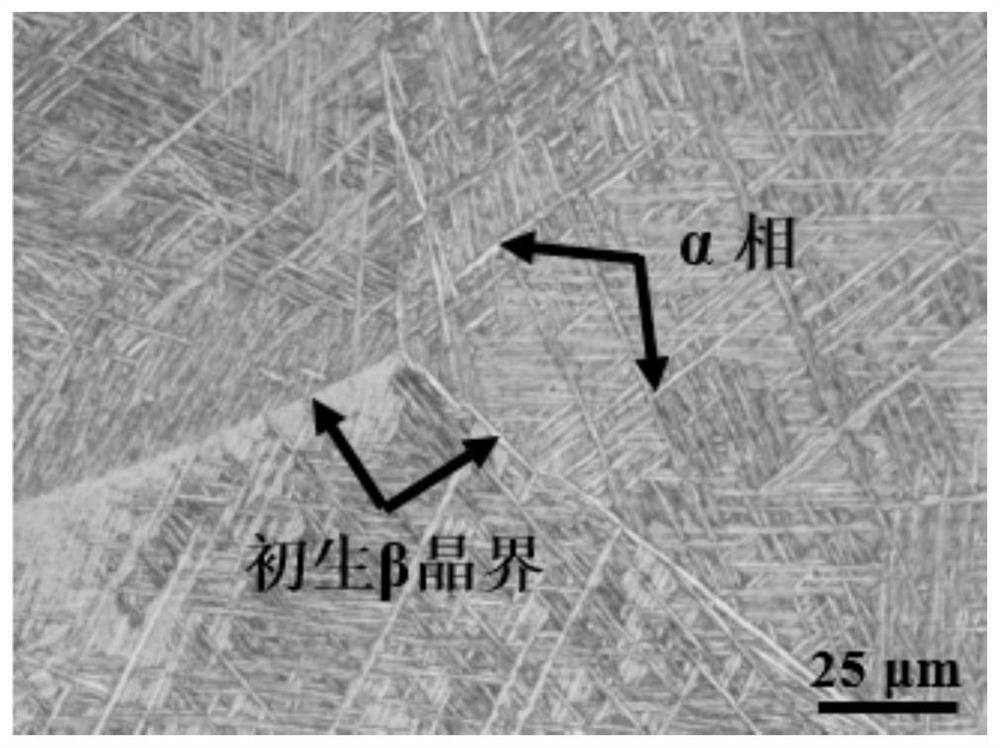

[0031] Such as figure 1 As shown, the Ti-6Al-3Nb-2Zr-1Mo-0.05C corrosion-resistant titanium alloy of the present embodiment is composed of the following raw materials by mass percentage: 6% Al, 3% Nb, 2% of Zr, 1% of Mo, 0.05% of C, and the rest of Ti.

[0032] The preparation method of the titanium alloy of the present embodiment is carried out as follows:

[0033] Step (1) Raw material preparation

[0034] Alloy raw materials are pure titanium (>99.4 wt%), pure aluminum wire (>99.9 wt%), pure niobium rod (>99.9 wt%), pure crystalline zirconium (>99.9 wt%), pure molybdenum sheet (>99.9 wt% ), graphite powder (>99.99 wt%).

[0035] Before smelting, the alloy raw materials (except graphite powder) were ultrasonically cleaned with acetone and ethanol for 10 minutes respectively; the present invention has no special requirements for the specific implementation of the ultrasonic cleaning, and those well-known to those skilled in the art can be used. .

[0036] Step (2) Smelti...

Embodiment 2

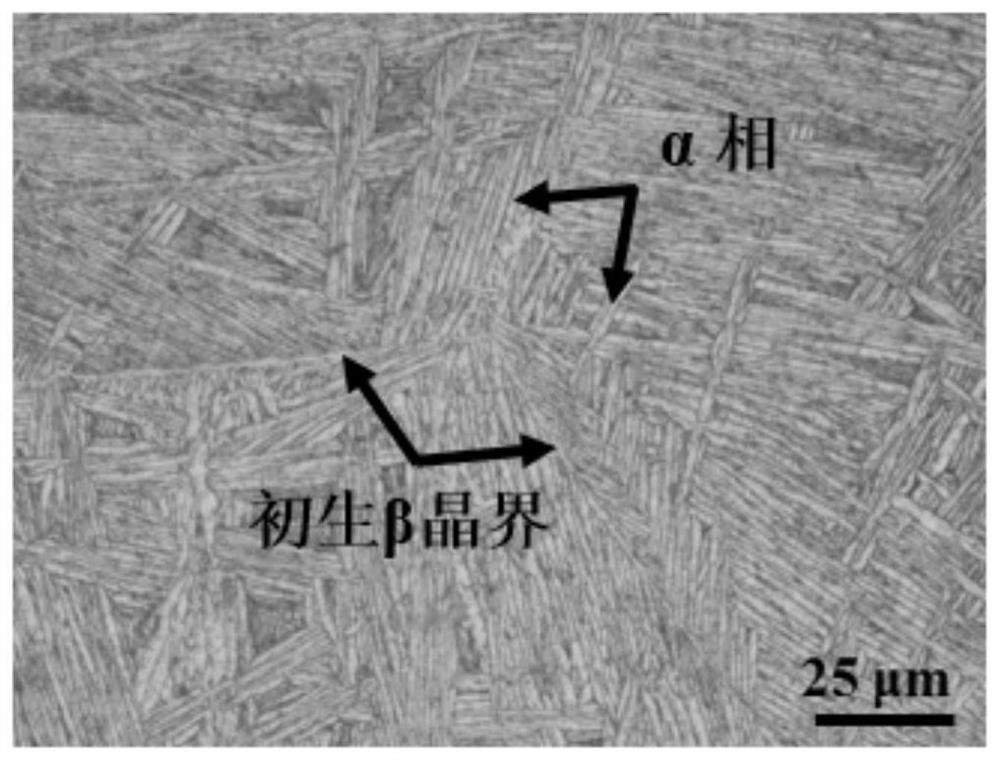

[0042] Such as figure 2 As shown, the Ti-6Al-3Nb-2Zr-1Mo-0.05C corrosion-resistant titanium alloy of this embodiment is composed of the following raw materials by mass percentage: 6% Al, 3% Nb, 2% Zr, 1% Mo, 0.1% C, and the rest Ti.

[0043] The preparation method of the titanium alloy of the present embodiment is carried out as follows:

[0044] Melting is vacuum non-consumable arc melting. When using vacuum non-consumable arc melting, the vacuum degree in the furnace chamber should be pumped to 5×10 -3 Below Pa, then argon gas is introduced to 0.05 MPa; the melting temperature is 2500° C.; the melting time is 2 minutes. In this embodiment, there is no special requirement for the specific implementation of the vacuum arc smelting, and those known to those skilled in the art can be used. In the present invention, the smelting is repeated six times to ensure uniform composition of the obtained ingot.

[0045] All the other are identical with embodiment 1.

Embodiment 3

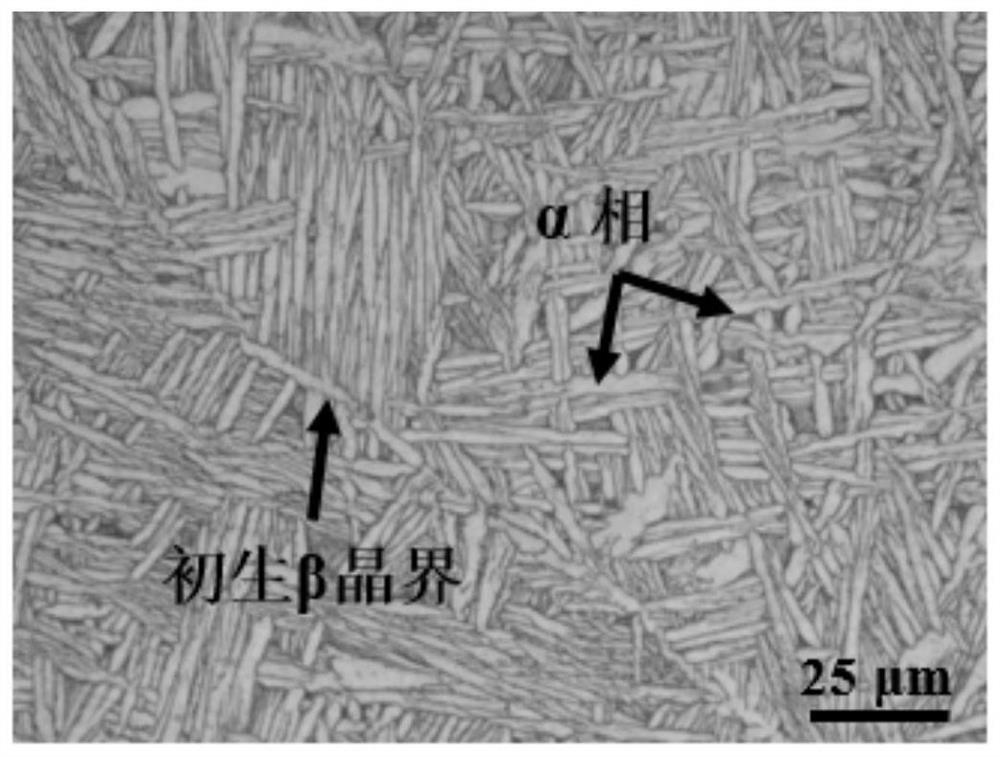

[0047] Such as image 3 As shown, the Ti-6Al-3Nb-2Zr-1Mo-0.15C corrosion-resistant titanium alloy of this embodiment is composed of the following raw materials by mass percentage: 6% Al, 3% Nb, 2% Zr, 1% Mo, 0.15% C, and the rest Ti.

[0048] The preparation method of the titanium alloy of the present embodiment is carried out as follows:

[0049] Melting is vacuum non-consumable arc melting. When using vacuum non-consumable arc melting, the vacuum degree in the furnace chamber should be pumped to 5×10 -3 Below Pa, then argon gas is introduced to 0.05 MPa; the melting temperature is 3000° C.; the melting time is 4 minutes. In this embodiment, there is no special requirement for the specific implementation of the vacuum arc smelting, and those known to those skilled in the art can be used. In the present invention, the smelting is repeated 10 times to ensure uniform composition of the obtained ingot.

[0050] All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com