Post-fermented dark tea and processing method thereof

一种加工方法、黑茶的技术,应用在后发酵黑茶及其加工领域,能够解决没有茶叶产品或研究报道等问题,达到降低咖啡碱含量、耐存储、克服苦涩味的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

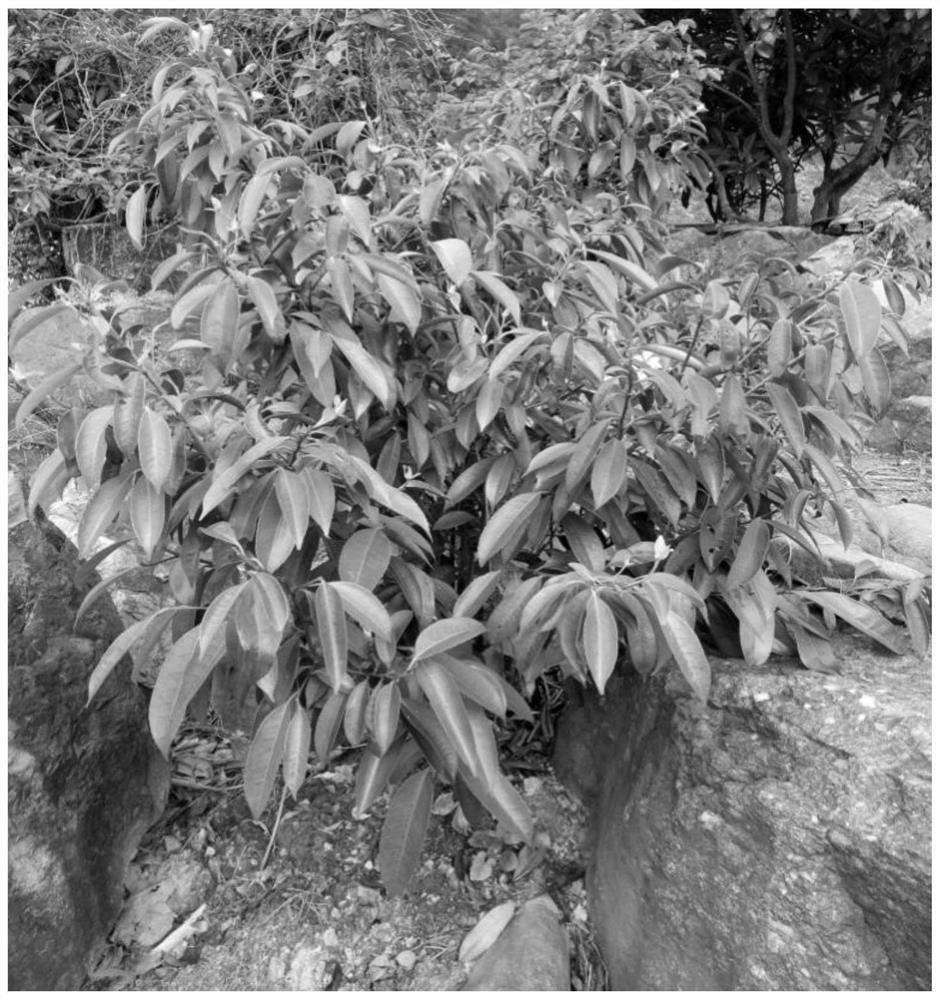

Image

Examples

Embodiment 1

[0082] A processing method for fermented black tea after blending, comprising the following steps:

[0083] 1. Post-fermentation dark tea and tooth-leaf red and light ratio green tea are prepared sequentially as follows:

[0084] 1.1 The preparation of post-fermentation dark tea comprises the following steps:

[0085] (1) Picking of fresh tea leaves: at 8-9 am on a sunny day, use hand-picked young buds of small-leaved species of the Theaceae tea tree, one bud with one leaf, one bud with two leaves, one bud with three leaves, one bud with four leaves or one bud Fresh leaves of five leaves. You can choose according to the grade of tea.

[0086] (2) Complete. The pine wood fire and iron barrel are used for 5-15 minutes, until the tea leaves have no green or astringent taste.

[0087] The present invention adopts firewood iron bucket to finish greening, uses pine wood to burn fire, makes tea absorb the rosy fragrance of pine wood. Because it is an ordinary iron barrel, there ...

Embodiment 2

[0132] A processing method of blended tea, comprising the steps of:

[0133] 1. The preparation method of post-fermented dark tea and tooth leaf red and light green tea is the same as in Example 1.

[0134] 2. Evenly mix the post-fermented black tea and the tooth-leaf red-light ratio green tea in a weight ratio of 6:4 to obtain a blended tea product.

[0135] 3. Product inspection

[0136] 3.1 Inspection indicators and inspection are the same as in Example 1.

[0137] 3.2 Test results

[0138] The test results are shown in Table 5.

[0139] Table 5. Inspection indicators and inspection results of blended tea

[0140] index content index content Moisture content (%) 6.64 Flavonoids (%) 1.58 Water leaching (%) 48.73 Caffeine (%) 1.91 Tea polyphenols (%) 18.95 Theaflavins (%) 0.93 Amino acid (%) 2.10 Thearubigin (%) 2.37 Soluble sugar (%) 6.20 Theabrownin (%) 2.32 Catechin (%) 5.61

[0141] The results ...

Embodiment 3

[0143] A processing method for blending tea, comprising the steps of:

[0144] 1. The preparation method of post-fermented dark tea and tooth leaf red and light green tea is the same as in Example 1.

[0145] 2. Evenly mix the post-fermented black tea and the tooth-leaf red-light ratio green tea according to the weight ratio of 8:2 to obtain a blended tea product.

[0146] 3. Product inspection

[0147] 3.1 Inspection index and inspection are the same as in Example 1.

[0148] 3.2 Test results

[0149] The test results are shown in Table 6.

[0150] Table 6. Inspection indicators and inspection results of blended tea

[0151] index content index content Moisture content (%) 7.87 Flavonoids (%) 1.59 Water leaching (%) 45.12 Caffeine (%) 2.21 Tea polyphenols (%) 21.18 Theaflavins (%) 1.24 Amino acid (%) 2.37 Thearubigin (%) 3.16 Soluble sugar (%) 4.93 Theabrownin (%) 3.10 Catechin (%) 5.07

[0152] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com