Oxygen-containing microporous activated carbon, preparation thereof and application of oxygen-containing microporous activated carbon in selective ethane adsorption

An activated carbon and selective technology, applied in the field of oxygen-containing microporous activated carbon and its preparation and application in selective adsorption of ethane, can solve the problems of low ethane/ethylene separation selectivity, complicated preparation process, and high production cost , to achieve good industrial application prospects, simple production process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

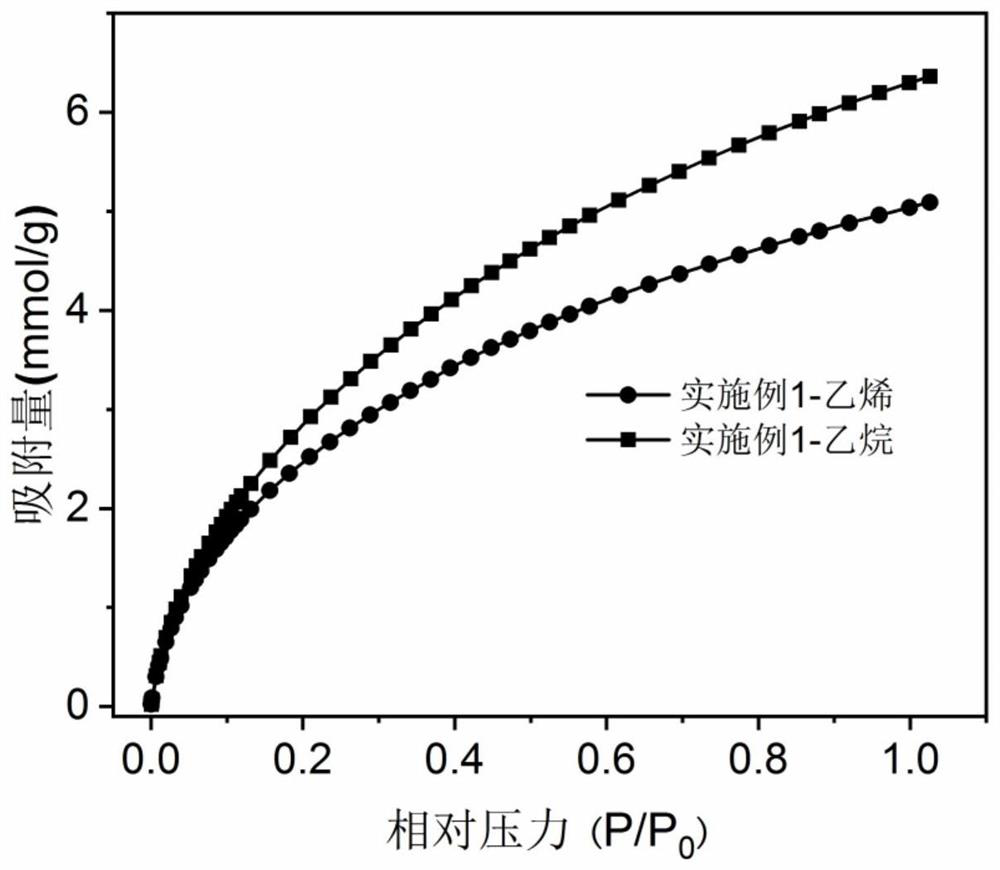

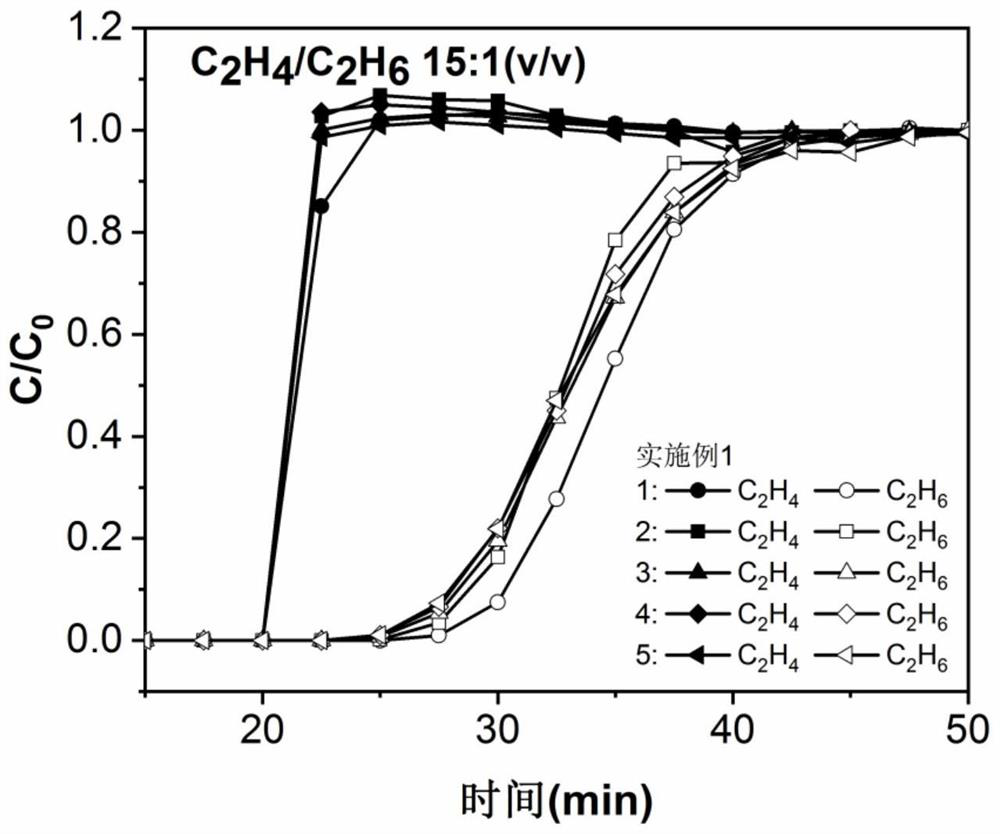

[0043] (1) Weigh 3g of coconut shell charcoal and 9g of KOH, grind, mix and dry. The dry carbon precursor is placed in a high-temperature tube furnace in a nitrogen atmosphere, and the temperature rises from room temperature to 800 °C at a rate of 10 °C / min. After activation for a period of time, it is cooled to room temperature, cleaned and dried to obtain oxygen-containing microporous activated carbon. The ethylene / ethane selectivity is 2.2, and the ethane adsorption capacity is 6.36mmol / g.

[0044] (2) Fill the oxygen-containing microporous activated carbon into the adsorption column. At 25°C and 1bar, the ethylene / ethane (15:1) mixture flows through the adsorption column at a flow rate of 5mL / min, and the end of the adsorption column obtains high-purity Ethylene gas (>99.99%), stop adsorption when the adsorption column is completely penetrated. At 100 °C, the adsorption column was purged with nitrogen to realize the regeneration of activated carbon.

[0045] (3) Fill the...

Embodiment 2

[0048] (1) Weigh 10 g of coconut shell and dry it, and activate it at 700° C. for 3 hours under nitrogen atmosphere to obtain about 8 g of coconut shell charcoal. Grind and mix the obtained coconut shell charcoal with 9g KOH, activate it under a nitrogen atmosphere at 900°C, wash and dry the product to neutrality, and dry it in vacuum to obtain an oxygen-containing microporous activated carbon material with an ethylene / ethane selectivity of 2.6 and an ethane adsorption capacity of 6.02 mmol / g.

[0049] (2) Fill the oxygen-containing microporous activated carbon into the adsorption column. At 20°C and 1 bar, the mixed gas of ethylene / ethane (1:10) flows through the adsorption column at a flow rate of 2mL / min, and the end of the adsorption column obtains high-purity Ethylene gas (>99.99%), stop adsorption when the adsorption column is completely penetrated. At 100 °C, the adsorption column was purged with nitrogen to realize the regeneration of activated carbon.

Embodiment 3

[0051] (1) Weigh 3g of coconut shell charcoal and 6g of KOH, grind, mix and dry. Place the dry carbon precursor in a high-temperature tube furnace in a nitrogen atmosphere, activate it at 800°C for 1 hour, cool to room temperature, wash and dry to obtain oxygen-containing microporous activated carbon, with an ethylene / ethane selectivity of 2.1 and an ethane adsorption capacity of 5.12 mmol / g.

[0052] (2) Fill the prepared oxygen-containing microporous activated carbon into the adsorption column, and at 15°C and 5bar, the mixed gas of ethylene / ethane (5:1) flows through the adsorption column at a flow rate of 15mL / min, and the end of the adsorption column obtains High-purity ethylene gas (>99.9%), when the adsorption column is completely penetrated, the adsorption will stop. At normal temperature, use a vacuum pump to desorb and regenerate, and the vacuum degree is 0.1 bar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Oxygen content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com