Novel C2NxO1-x/PIM-1 mixed matrix membrane and preparation method and application thereof

A technology of PIM-1 and mixed matrix membrane, applied in separation methods, chemical instruments and methods, membrane technology, etc., to achieve good economic benefits and commercialization prospects, high gas permeability, and simple and easy preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

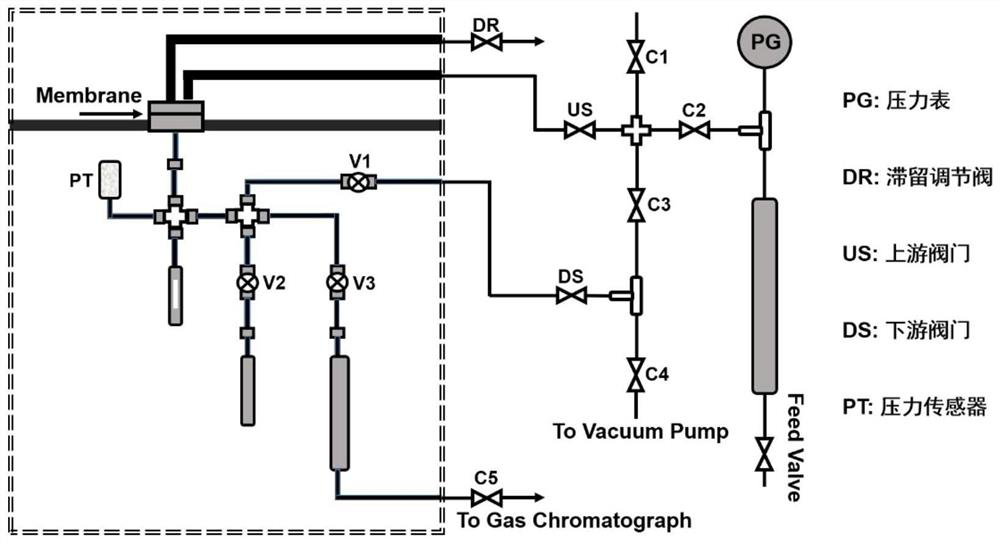

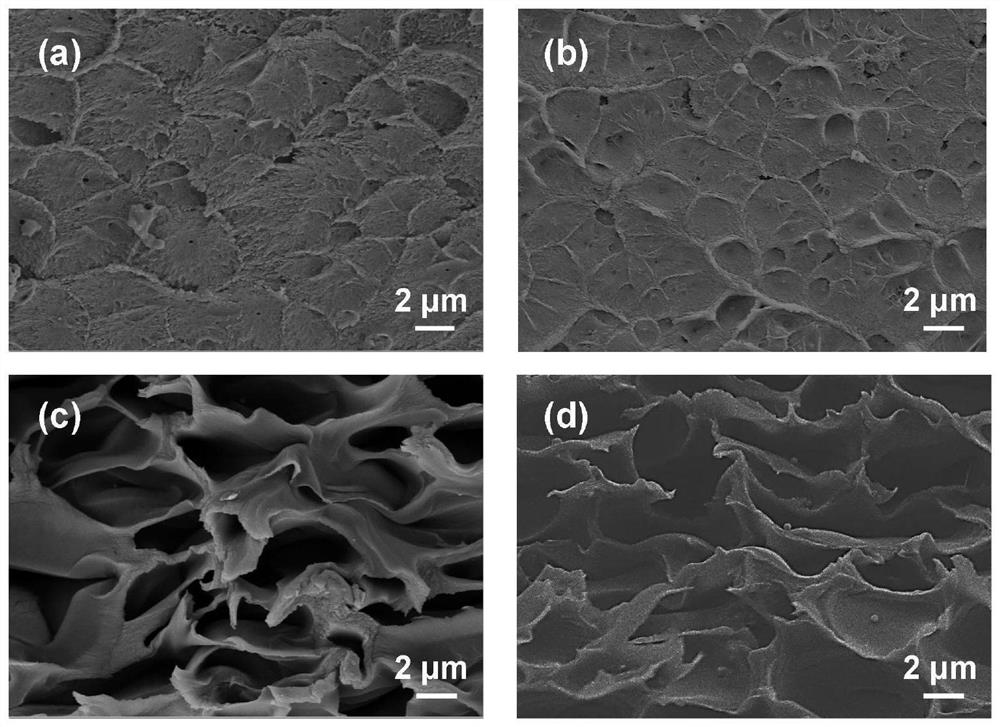

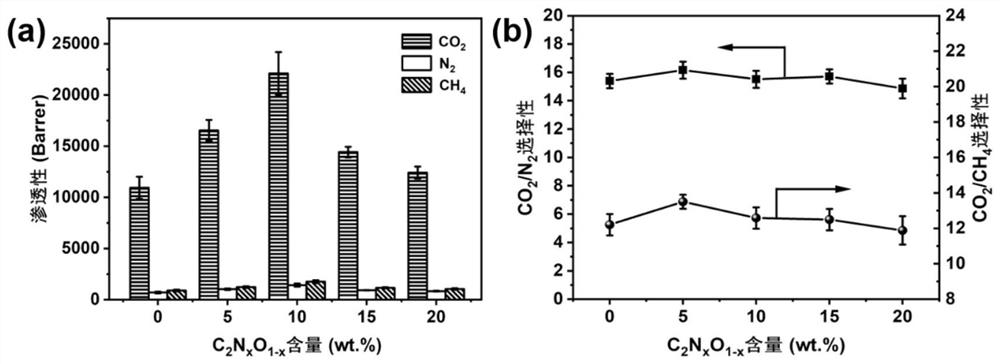

Method used

Image

Examples

Embodiment 1

[0040] New type C 2 N x o 1-x / PIM-1 mixed matrix membrane preparation, the steps are as follows:

[0041] 1. Configure PIM-1 solution

[0042] Synthesis of PIM-1: Weigh 5.106g of purified 5,5',6,6'-tetrahydroxy-3,3',4,4'-tetramethyl-1,1'-helical bisindane ( TTSBI) in a three-necked flask, add 30ml of anhydrous N,N-dimethylacetamide (DMAc) under a nitrogen atmosphere, stir and dissolve, and add 3.001g of recrystallized tetrafluoroterephthalonitrile after TTSBI is completely dissolved (TFTPN) and continue stirring, stop stirring after all medicines are dissolved, add 6.21g of anhydrous potassium carbonate, then transfer the three-necked flask to 150°C oil bath and keep stirring. The polycondensation reaction continued, and the reactant became viscous at this time, and 2-3ml of anhydrous toluene was added several times, and the whole reaction continued for 30 minutes. After cooling to room temperature, the product was poured into 400 ml of anhydrous methanol, and precipitat...

Embodiment 2

[0063] Step 2 Take 0.1g PEG-200 and add to C 2 N x o 1-x In the dispersion, stir for 4h and sonicate for 1h. Other steps are all with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com