Zirconium pyrophosphate-based mixed conductor hydrogen permeation membrane material with layered structure and capable of being operated at medium and low temperature as well as preparation method and application of zirconium pyrophosphate-based mixed conductor hydrogen permeation membrane material

A zirconium pyrophosphate-based, layered structure technology, applied in separation methods, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems such as chemically stable hydrogen permeable membrane materials that have not yet been developed, and achieve the benefits of sintering and densification , excellent compactness and high hydrogen permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A magnesium ion-doped layered zirconium pyrophosphate-based mixed conductor hydrogen permeable membrane material Zr that can be operated at medium and low temperatures in this embodiment 0.9 Mg 0.1 P 2 o 7-δ (ZMP10) preparation method, wherein δ=0~0.2, comprises the following steps:

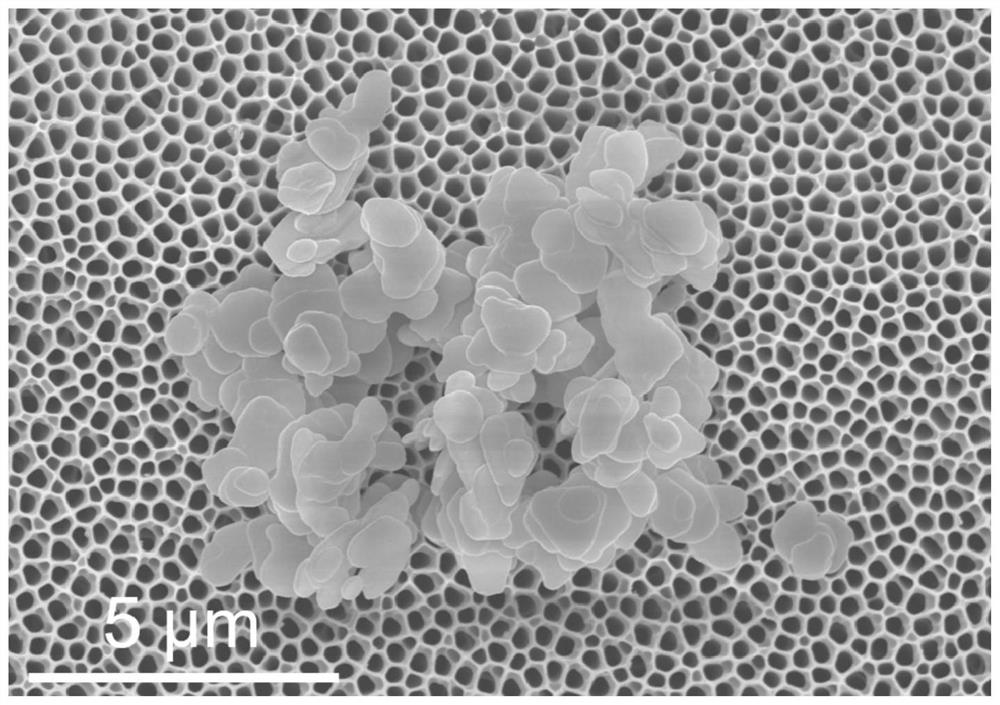

[0040] (1) Synthesis of ZMP10: Weigh 9.854g Zr(HPO 4 ) 2 ·H 2 O, 0.146g MgO, measure 0.62ml H 3 PO 4 , add 20ml ethanol after initial mixing, carry out ball milling with the rotating speed of 500r / min, take out after 12h and dry naturally, the raw material layer structure Zr(HPO 4 ) 2 ·H 2 The scanning electron microscope image of O is shown in figure 1 shown, where the H 3 PO 4 The mass concentration is 85%.

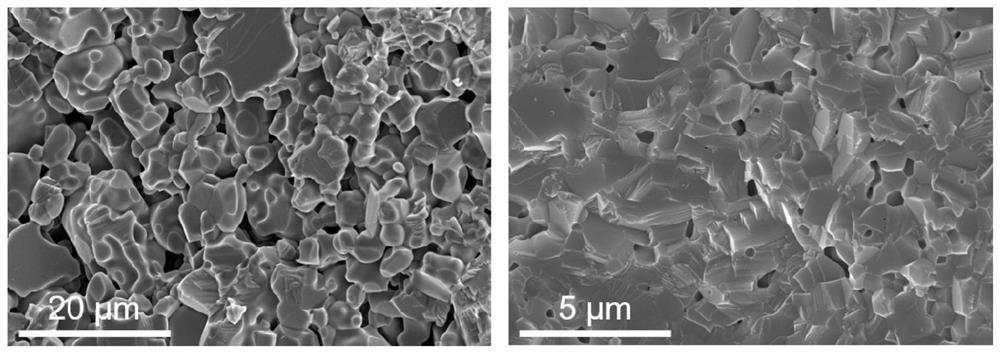

[0041] (2) Put the ZMP10 raw material powder obtained by ball milling into a high-temperature muffle furnace to raise the temperature to 750°C at a heating rate of 2°C / min, keep it warm for 5 hours, and then lower it to room temperature at a rate of 2°C / min to obtain ZM...

Embodiment 2

[0064] A copper ion-doped zirconium pyrophosphate-based mixed conductor hydrogen permeable membrane material Zr with a layered structure that can be operated at medium and low temperatures in this embodiment 0.95 Cu 0.05 P2O 7-δ (ZCP5) preparation method, wherein δ=0~0.1, specifically comprises the following steps:

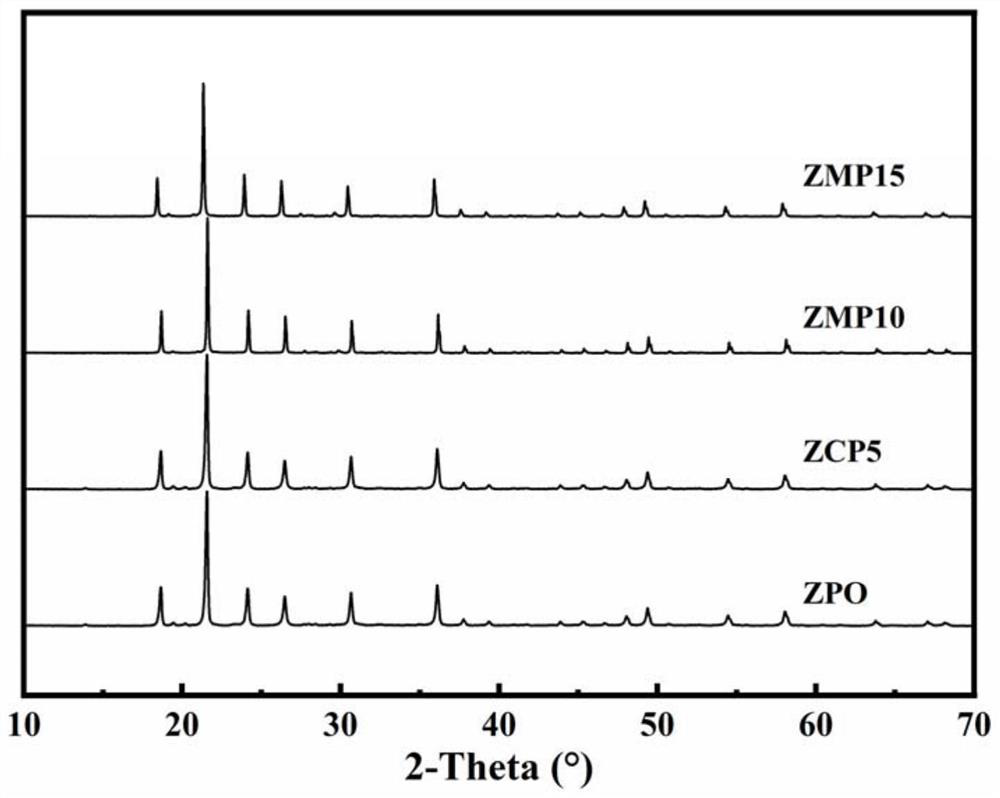

[0065] (1) Weigh 9.863g Zr(HPO 4 ) 2 ·H 2 O, 0.137g CuO, measure 0.46ml H 3 PO 4 After initial mixing, 20ml of ethanol was added, and ball milling was performed at a speed of 400r / min. After 10 hours, it was taken out and dried naturally; the dried ZCP5 powder was placed in a high-temperature muffle furnace and raised to 600°C at a heating rate of 1°C / min, and Keep it warm for 10 hours, then lower it to room temperature at a rate of 1°C / min to obtain a phase-formed powder. The obtained powder was subjected to phase analysis, and the results were as follows: figure 2 As shown, the material maintains the original cubic phase structure after doping copper, a...

Embodiment 3

[0068] A layered zirconium pyrophosphate-based mixed conductor material Zr doped with magnesium ions that can be operated at medium and low temperatures in this embodiment 0.85 Mg 0.15 P 2 o 7-δ The preparation method of (ZMP15), wherein δ=0~0.5, specifically comprises the following steps:

[0069] (1) Weigh 8.694g Zr(HPO 4 ) 2 ·H 2 O, 1.306g Mg(NO 3 ) 2 , measure 1.36ml H 3 PO 4 , add 20ml of ethanol after preliminary mixing, ball mill at a speed of 400r / min, take out and dry naturally after 12h; place the dried powder in a high-temperature muffle furnace to raise the temperature to 800°C at a heating rate of 1°C / min, and keep it warm 10h, and then lowered to room temperature at a rate of 1°C / min to obtain a phase-formed powder. The obtained powder was subjected to phase analysis, and the results were as follows: figure 2 As shown, the material maintains the original cubic phase structure after doping with magnesium, and no other impurity phases are formed. Among ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com