Brazing filler metal paste for stainless steel flux-free brazing, preparation method of brazing filler metal paste, copper-manganese-nickel-cobalt brazing filler metal and application thereof

A solder paste, stainless steel technology, used in welding equipment, welding/cutting media/materials, welding media, etc., can solve problems such as pollution of the environment, leakage, and growth of stainless steel grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation method of the solder paste for stainless steel flux-free brazing of the present embodiment, the parts by weight of the raw materials used consist of: 70 parts of copper-based solder powder, 3 parts of nano silicon dioxide, 3 parts of sodium hydroxide, 10 parts of deionized water; the mass percent of each component in the copper-based solder powder is: Mn26.0%, Ni26.0%, Co4.0%, B0.1%, Li0.1%, Na0.1% , K0.01%, Cu balance.

[0038] Prepared using the following steps:

[0039] (1) Take each component in proportion, and first dissolve sodium hydroxide in deionized water to form an alkaline aqueous solution for subsequent use;

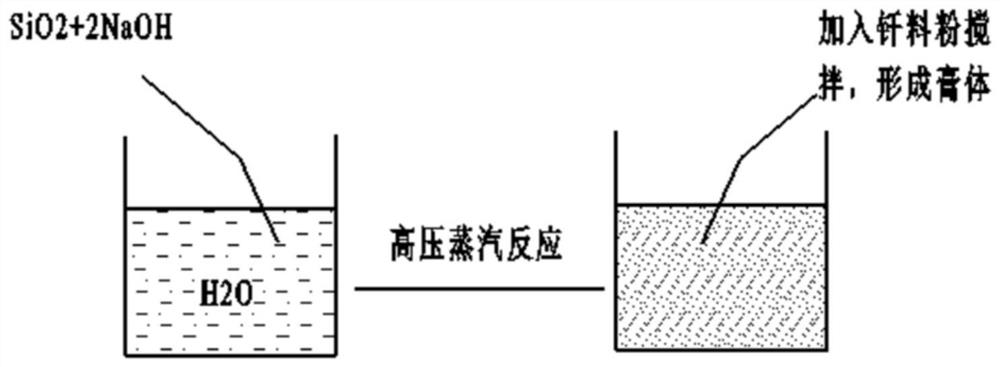

[0040] (2) Add nano-silica (30-50nm) into step (1) alkaline aqueous solution, put it in a high-pressure reactor, and react for 3.0 hours under 0.3MPa steam pressure to form a suspension (transparent colloidal liquid + a small amount of silicon dioxide); the schematic diagram of the reaction process is as figure 1 shown;

[0041] (3...

Embodiment 2

[0043]The preparation method of the solder paste for stainless steel flux-free brazing of the present embodiment, the parts by weight of the raw materials used consist of: 72 parts of copper-based solder powder, 4 parts of nano silicon dioxide, 2 parts of sodium hydroxide, 11 parts of deionized water; the mass percent of each component in the copper-based solder powder is: Mn27.0%, Ni27.0%, Co5.0%, B0.2%, Li0.2%, Na0.1% , K0.1%, Cu balance. The specific preparation method is basically the same as that of Example 1, except that in step (2), the steam pressure is 0.4 MPa, and the reaction time is 4.0 h.

Embodiment 3

[0045] The preparation method of the solder paste for stainless steel flux-free brazing of the present embodiment, the parts by weight of the raw materials used consist of: 74 parts of copper-based solder powder, 5 parts of nano silicon dioxide, 1 part of sodium hydroxide, 12 parts deionized water. The mass percentage of each component in copper-based solder powder is: Mn28.0%, Ni28.0%, Co6.0%, B0.3%, Li0.4%, Na0.2%, K0.15%, Cu margin.

[0046] The specific preparation method is basically the same as that of Example 1, except that in step (2), the steam pressure is 0.5 MPa, and the reaction time is 5.0 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap