Method for activating waste rock wool and application of activated waste rock wool

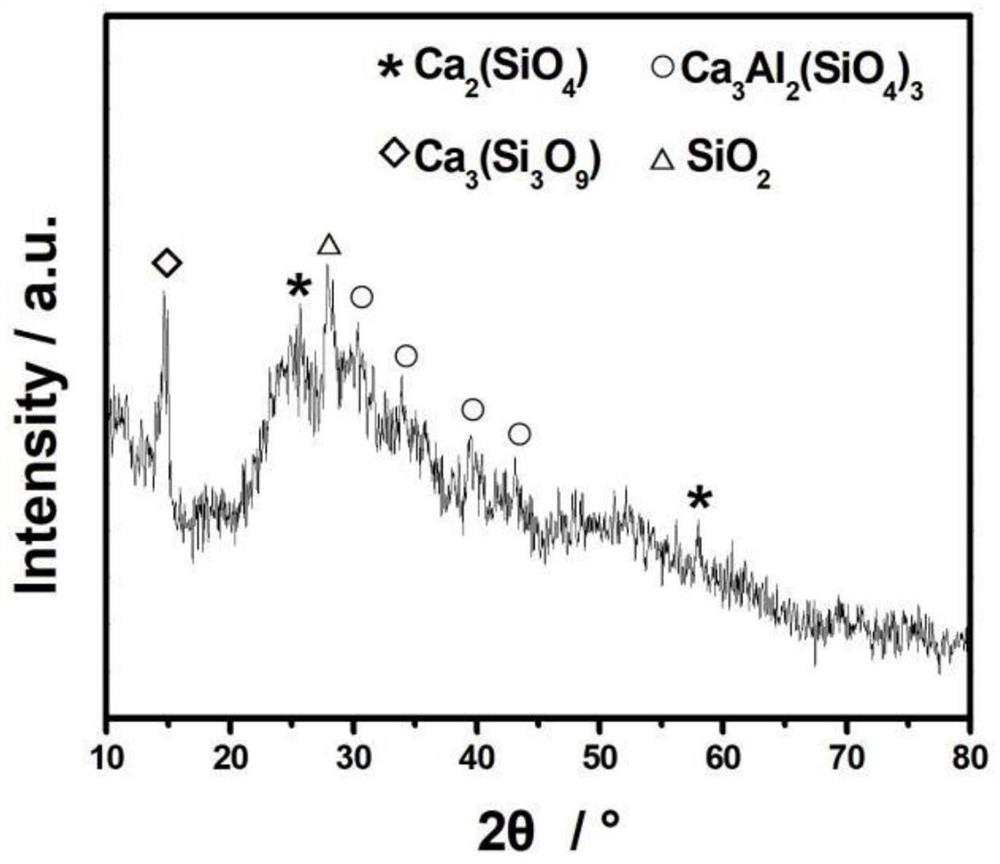

An activation method and technology for rock wool are applied in the activation of waste rock wool and the application field of activated waste rock wool, which can solve the problems of low glass body content of waste rock wool, adverse effects on material properties, weak pozzolanic reaction ability, etc., and achieve energy saving. consumption, achieve harmless treatment, and improve the effect of activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

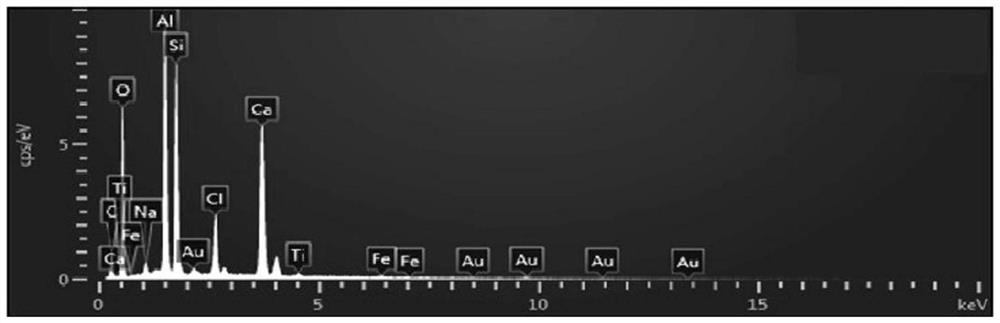

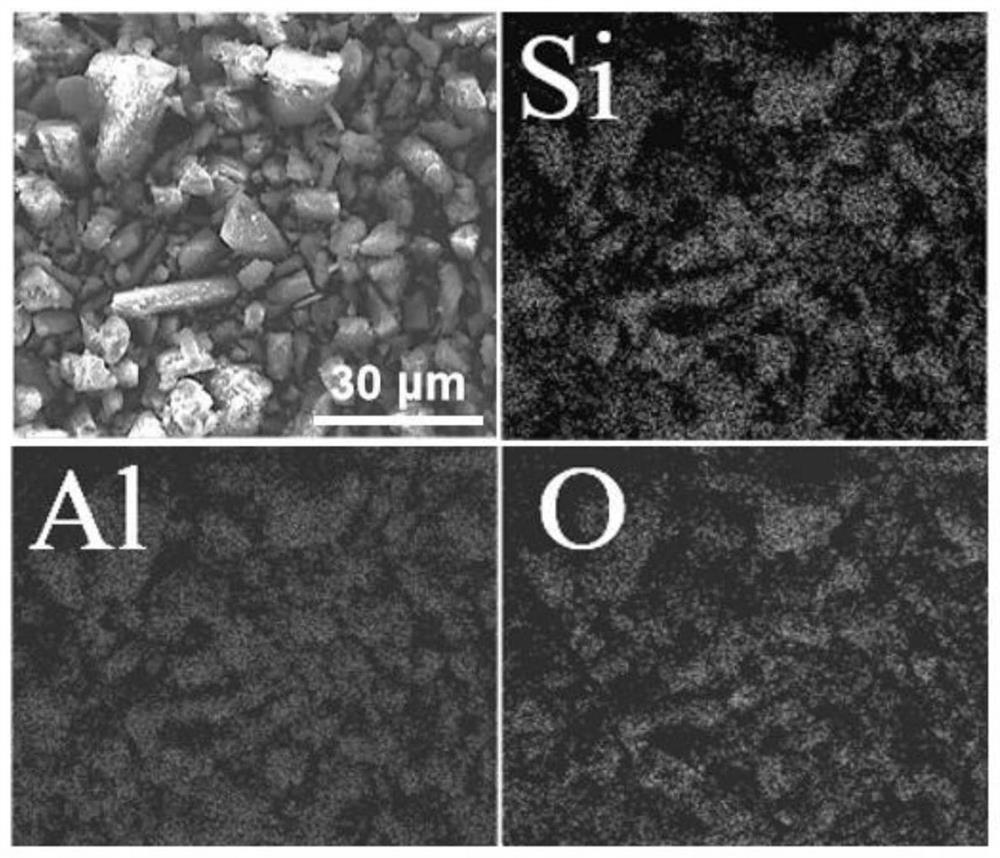

Method used

Image

Examples

Embodiment 1

[0042] A kind of activation method of waste rock wool that embodiment 1 provides, comprises the following steps:

[0043] (1) 3 kg of chlorinated salt anhydrous CaCl with a purity of 95% 2 Put it into a graphite reaction vessel with a diameter of 20 cm, and heat it to CaCl in an electric furnace under the protection of an inert gas. 2 Melt, then adjust the molten salt temperature to 820°C;

[0044] (2) Cut the waste rock wool board into pieces, take a piece of 8*8*2cm, and fix it on one end of the iron wire. Then, under an inert atmosphere, one end of the iron wire loaded with rock wool was immersed in molten CaCl 2 During the process, ensure that the rock wool waste is completely submerged in the molten salt for 7 hours;

[0045] (3) After the soaking operation is finished, the waste rock wool is taken out from the molten salt, and the molten salt adsorbed inside the waste rock wool is drained by plate pressing under an inert atmosphere;

[0046] (4) In a dry environment,...

Embodiment 2

[0051] Example 2 provides an application of activated waste rock wool. Specifically, the activated waste rock wool prepared in Example 1 is prepared with Portland cement clinker and fly ash at a ratio of 1:3.5:0.5 to obtain a composite Cementitious material; the obtained composite cementitious material is mixed with municipal sludge in a certain place and cured.

[0052] see Figure 4 as shown, Figure 4 It is the change of water content after the composite cementitious material obtained in Example 2 is mixed with municipal sludge in a certain place and cured. It can be seen from the figure that the sludge is increased with the number of maintenance days after adding the cementitious material prepared by the method of the present invention. , and its moisture content is significantly reduced. It shows that the cementitious material prepared after activation treatment of waste rock wool is used for sludge solidification treatment, and the effect of water reduction and solidif...

Embodiment 3

[0054] A kind of activation method of waste rock wool provided by embodiment 3, compared with embodiment 1, the difference is that in step (1), the chloride salt used is anhydrous NaCl-CaCl 2 , and others are substantially the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com