A kind of preparation method of ceramic-based core-shell fiber

A ceramic-based, core-shell technology, applied in fiber processing, fiber chemical characteristics, textiles and papermaking, etc., can solve problems such as difficult equipment cleaning, high equipment requirements, and complicated processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

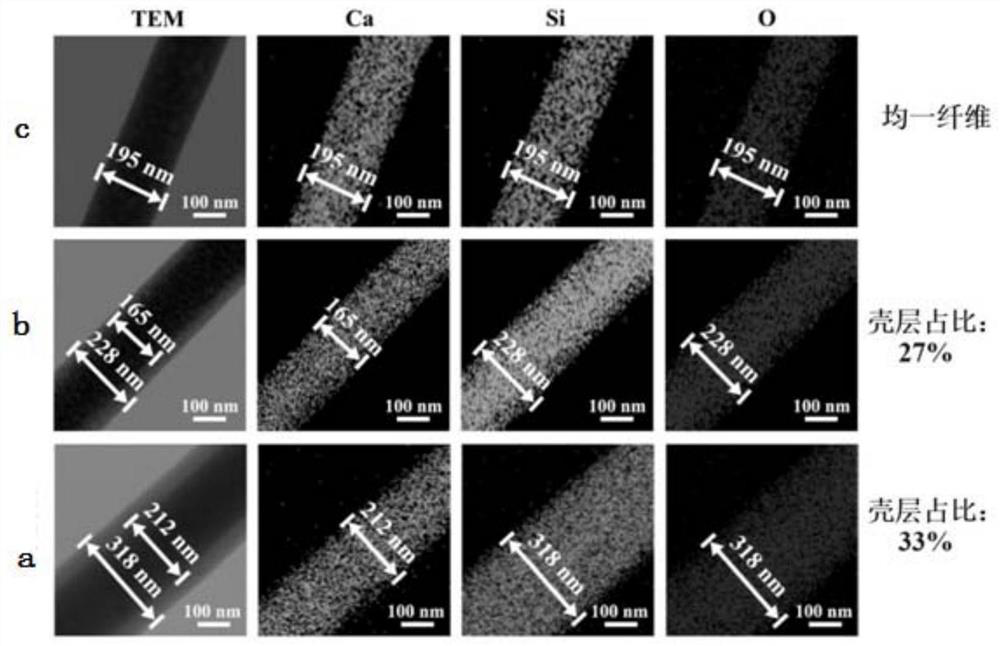

[0027] In an embodiment of the present invention, a method for preparing a ceramic-based core-shell fiber includes the following steps;

[0028] The calcium source material is added to the solvent, and after it is completely dissolved under ultrasonic conditions, the silicon source material is continuously added, reacted in an acidic environment, and aged for 2d-4d under stirring at 35°C-40°C to obtain a ceramic material precursor solution;

[0029] Dissolving the spinning aid in ethanol to obtain mixed solution A;

[0030] The ceramic material precursor solution and the mixed solution A are mixed according to the mass ratio of 1:1, and then placed in a water bath at 35°C to 40°C for ageing and stirring for 2d-4d to obtain a spinning solution;

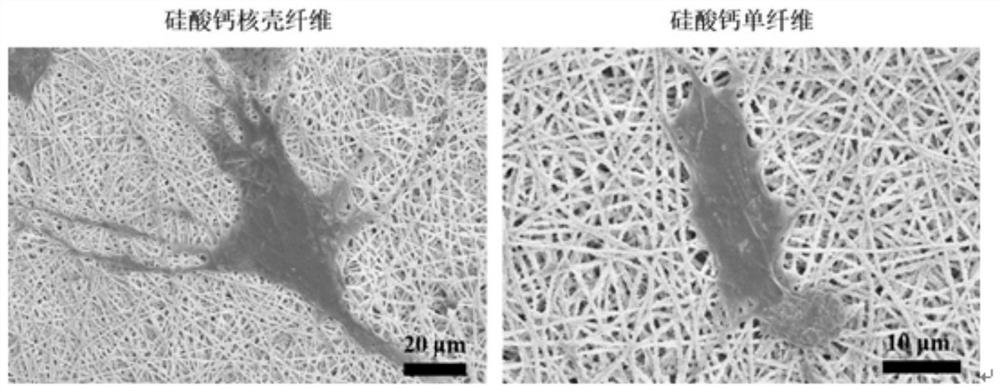

[0031] preparing the spinning solution by electrospinning to obtain a fiber membrane;

[0032] The fiber membrane is placed in a muffle furnace for sintering treatment, and then naturally cooled to room temperature to obtain a ceramic...

Embodiment 1

[0053] Add 7.56g of calcium nitrate tetrahydrate to 15mL of ethanol, add 15.14g of tetraethyl orthosilicate after ultrasonic dissolution is complete, and add 1mol hydrochloric acid to adjust the pH to 3, so that the reaction system is stirred and aged at 40°C in an acidic environment. 2d to obtain a ceramic material precursor solution;

[0054] Dissolving polyvinyl butyral ethanol in ethanol to obtain a mixed solution A in which the polyvinyl butyral ethanol accounts for 10wt% of the mixed solution A;

[0055] Mix 10 g of the ceramic material precursor solution and 10 g of the mixed solution A, and then place it in a water bath at 35° C. for aging and stirring for 4 d to obtain a spinning solution;

[0056] The spinning solution is prepared by an electrospinning method to obtain a fiber membrane, and the conditions of the electrospinning are: the moving speed of the slider is 40mm / min, the distance between the metal electrode and the receiving non-woven fabric is 22cmcm, The ...

Embodiment 2

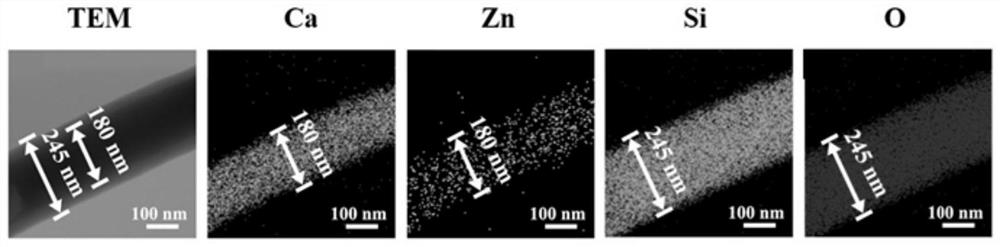

[0059] Add 15.12g of calcium nitrate tetrahydrate into 15mL of ethanol, add 15.14g of tetraethyl orthosilicate after ultrasonic dissolution is complete, and add 1mol of hydrochloric acid to adjust the pH to 3, so that the reaction system is stirred at 40°C in an acidic environment. 2d to obtain a ceramic material precursor solution;

[0060] Dissolving polyvinyl butyral ethanol in ethanol to obtain a mixed solution A in which the polyvinyl butyral ethanol accounts for 10wt% of the mixed solution A;

[0061] Mix 10 g of the ceramic material precursor solution and 10 g of the mixed solution A, and then place it in a water bath at 35° C. for aging and stirring for 4 d to obtain a spinning solution;

[0062] The spinning solution is prepared by an electrospinning method to obtain a fiber film, and the conditions of the electrospinning are: the moving speed of the slider is 40 mm / min, the distance between the metal electrode and the receiving non-woven fabric is 25 cm, The voltage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com