Method for detecting thermal stability of of electrode material of lithium ion battery

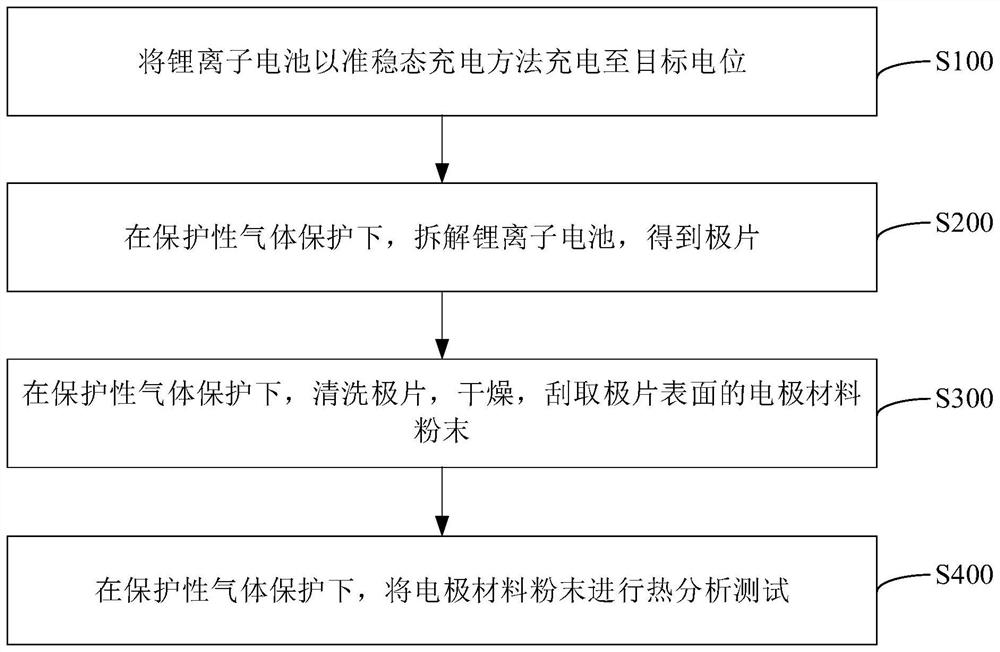

A technology for lithium ion batteries and electrode materials, which is applied in the field of detection of thermal stability of electrode materials for lithium ion batteries, can solve the problems of thermal stability, poor safety, affecting battery safety performance, and difficulty in accurately measuring the thermal stability of positive electrode materials. , to achieve the effect of reducing polarization resistance and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

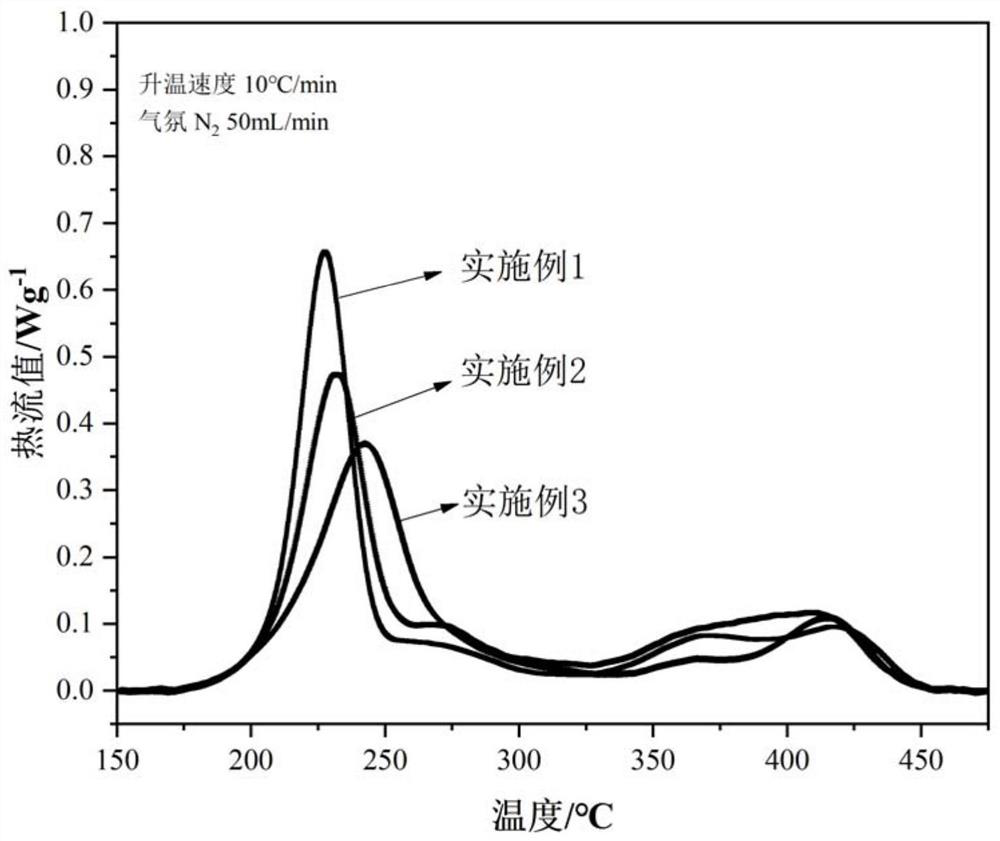

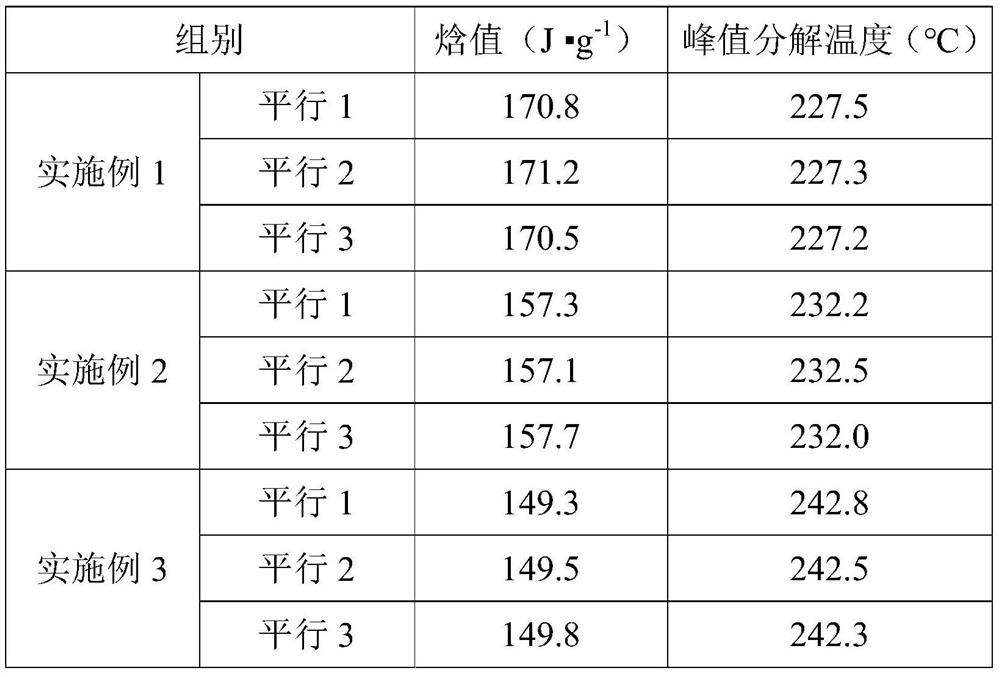

[0057] (1) The positive electrode material is a ternary high-nickel material LiNi 0.8 co 0.1 mn 0.1 o 2 The pouch battery was charged to 4.25V by galvanostatic intermittent titration (GITT). The GITT pulse current was 0.05C, the constant current time was 18min, and the relaxation time was 30min.

[0058] (2) Then, in the glove box, the pouch battery was disassembled, the positive electrode piece was taken out, washed three times in dichloromethane solvent, and dried.

[0059] (3) First weigh the weight of the high-pressure crucible, then in the glove box, scrape a certain amount of positive electrode material powder on the surface of the positive electrode sheet, put it into the high-pressure crucible and seal it, weigh the high-pressure crucible again, and the weight difference between the front and back of the high-pressure crucible is The weight of the scraped cathode material powder.

[0060] (4) Transfer the sealed high-pressure crucible to a differential scanning ca...

Embodiment 2

[0062] (1) The positive electrode material is a ternary high-nickel material LiNi 0.8 co 0.1 mn 0.1 o 2 The pouch battery was charged to 4.1V by galvanostatic intermittent titration (GITT). The GITT pulse current was 0.05C, the constant current time was 18min, and the relaxation time was 30min.

[0063] (2) Then, in the glove box, the pouch battery was disassembled, the positive electrode piece was taken out, washed three times in dichloromethane solvent, and dried.

[0064] (3) First weigh the weight of the high-pressure crucible, then in the glove box, scrape a certain amount of positive electrode material powder on the surface of the positive electrode sheet, put it into the high-pressure crucible and seal it, weigh the high-pressure crucible again, and the weight difference between the front and back of the high-pressure crucible is The weight of the scraped cathode material powder.

[0065] (4) Transfer the sealed high-pressure crucible to a differential scanning cal...

Embodiment 3

[0067] (1) The positive electrode material is a ternary high-nickel material LiNi 0.8 co 0.1 mn 0.1 o 2 The pouch battery was charged to 4.0V by galvanostatic intermittent titration (GITT). The GITT pulse current was 0.05C, the constant current time was 18min, and the relaxation time was 30min.

[0068] (2) Then, in the glove box, the pouch battery was disassembled, the positive electrode piece was taken out, washed three times in dichloromethane solvent, and dried.

[0069] (3) First weigh the weight of the high-pressure crucible, then in the glove box, scrape a certain amount of positive electrode material powder on the surface of the positive electrode sheet, put it into the high-pressure crucible and seal it, weigh the high-pressure crucible again, and the weight difference between the front and back of the high-pressure crucible is The weight of the scraped cathode material powder.

[0070] (4) Transfer the sealed high-pressure crucible to a differential scanning cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com