Insecticidal and bactericidal composition and application thereof

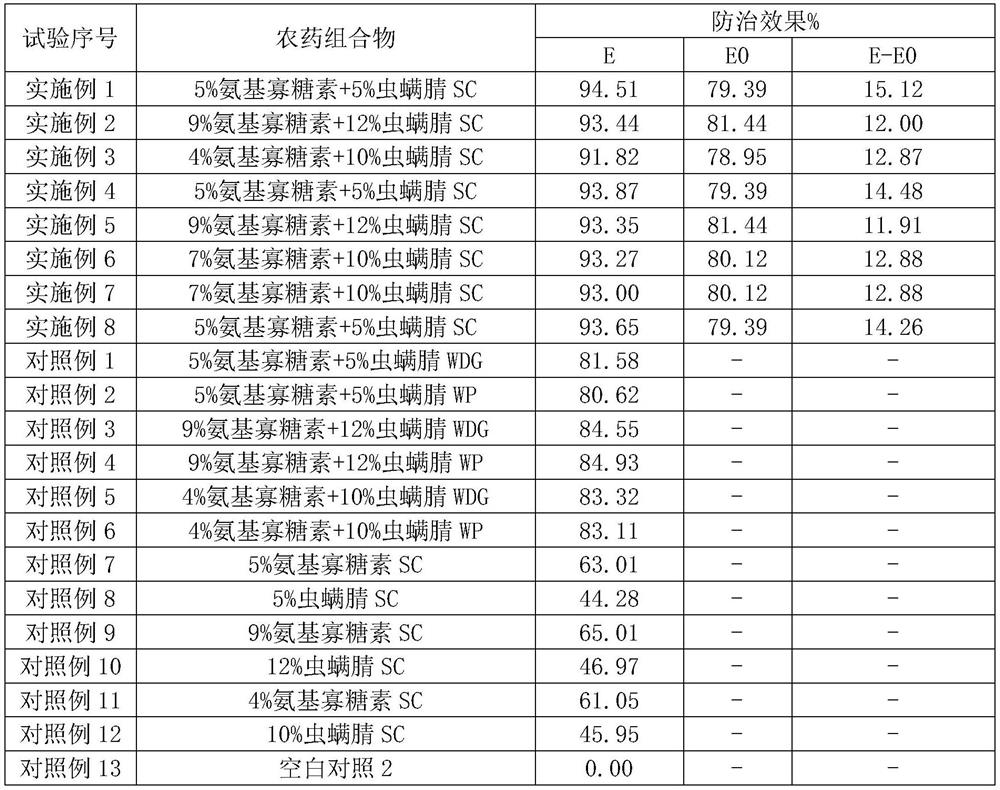

An insecticidal sterilization and composition technology, applied in the field of pesticides, can solve problems such as difficult to comprehensively control diseases and insect pests, and achieve the effects of strong synergistic effect, wide control spectrum and alleviation of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

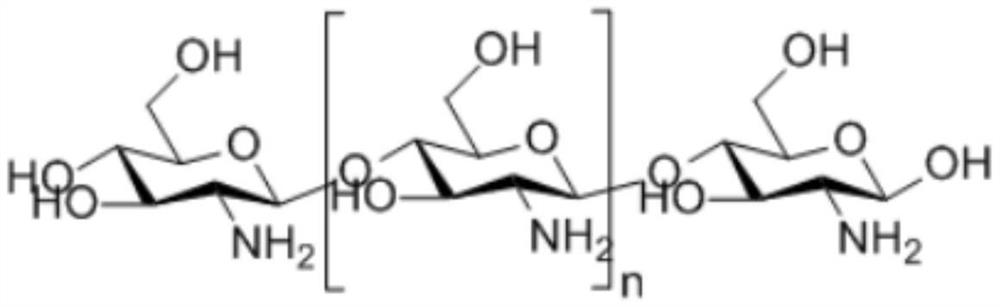

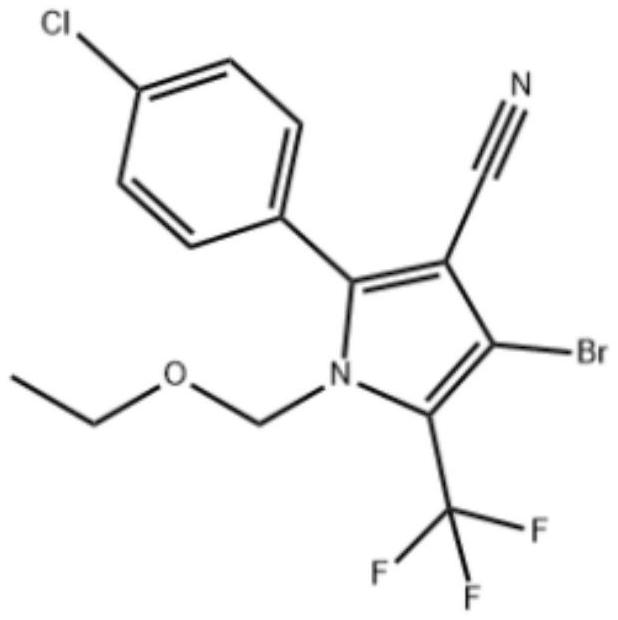

[0041] The composition of 10% oligosaccharin and chlorfenapyr suspension concentrate is composed of the following mass percentages (the mass ratio of oligosaccharin and chlorfenapyr is 1:1):

[0042] Amino oligosaccharin 5%, chlorfenapyr 5%, sodium lignosulfonate 8%, xanthan gum 0.20%, polyether modified polysiloxane defoamer 0.20%, bentonite 2%, sorbic acid 0.2%, lemon Acid 2%, urea 5%, sodium 1-naphthalene acetate 0.50%, deionized water to make up to 100%.

[0043] Preparation method: According to the formula, weigh the above components according to the proportion of the components, add a certain amount of original medicine, dispersing wetting agent, defoamer, and water into the mixing tank, stir evenly, and shear for 30 minutes (2200rpm) , and finally put it into a sand mill at 1800r / min for 2 hours, then discharge the material, and filter to obtain the finished product of 10% oligosaccharin and chlorfenapyr suspension concentrate.

Embodiment 2

[0045] The composition of 21% oligosaccharin and chlorfenapyr suspension concentrate is composed of the following mass percentages (the mass ratio of oligosaccharin and chlorfenapyr is 3:4):

[0046] Amino oligosaccharin 9%, chlorfenapyr 12%, EO / PO block copolymer 10%, xanthan gum 0.20%, polyether modified polysiloxane defoamer 0.20%, bentonite 2%, sorbic acid 0.2 %, citric acid 2%, urea 5%, 1-sodium naphthalene acetate 0.50%, and deionized water to make up to 100%.

[0047] Preparation method: According to the formula, weigh the above components according to the proportion of the components, add a certain amount of original medicine, dispersing wetting agent, defoamer, and water into the mixing tank, stir evenly, and shear for 30 minutes (2200rpm) , and finally put it into a sand mill for 2 hours of grinding at 1800r / min, discharge the material, and filter to obtain the finished product of 21% oligosaccharin and chlorfenapyr suspension concentrate.

Embodiment 3

[0049] The composition of the 14% oligosaccharin and chlorfenapyr suspension concentrate is composed of the following mass percentages (the mass ratio of oligosaccharin and chlorfenapyr is 2:5):

[0050] Amino oligosaccharin 4%, chlorfenapyr 10%, sodium lignosulfonate 8%, xanthan gum 0.20%, polyether modified polysiloxane defoamer 0.20%, bentonite 2%, sorbic acid 0.2%, lemon Acid 2%, urea 5%, sodium 1-naphthalene acetate 0.50%, deionized water to make up to 100%.

[0051] Preparation method: According to the formula, weigh the above components according to the proportion of the components, add a certain amount of original medicine, dispersing wetting agent, defoamer, and water into the mixing tank, stir evenly, and shear for 30 minutes (2200rpm) , and finally put it into a sand mill at 1800r / min to grind for 2 hours, discharge the material, and filter to obtain the finished product of 14% oligosaccharin and chlorfenapyr suspension concentrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com