Chloride ion intercalated LDHs as well as preparation method and application thereof

A technology of chloride ion and intercalation, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve problems such as long time consumption, poor nitrate selectivity, and complicated LDHs preparation process, and achieve The effect of less time consumption, no loss of adsorbent, and excellent nitrate adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

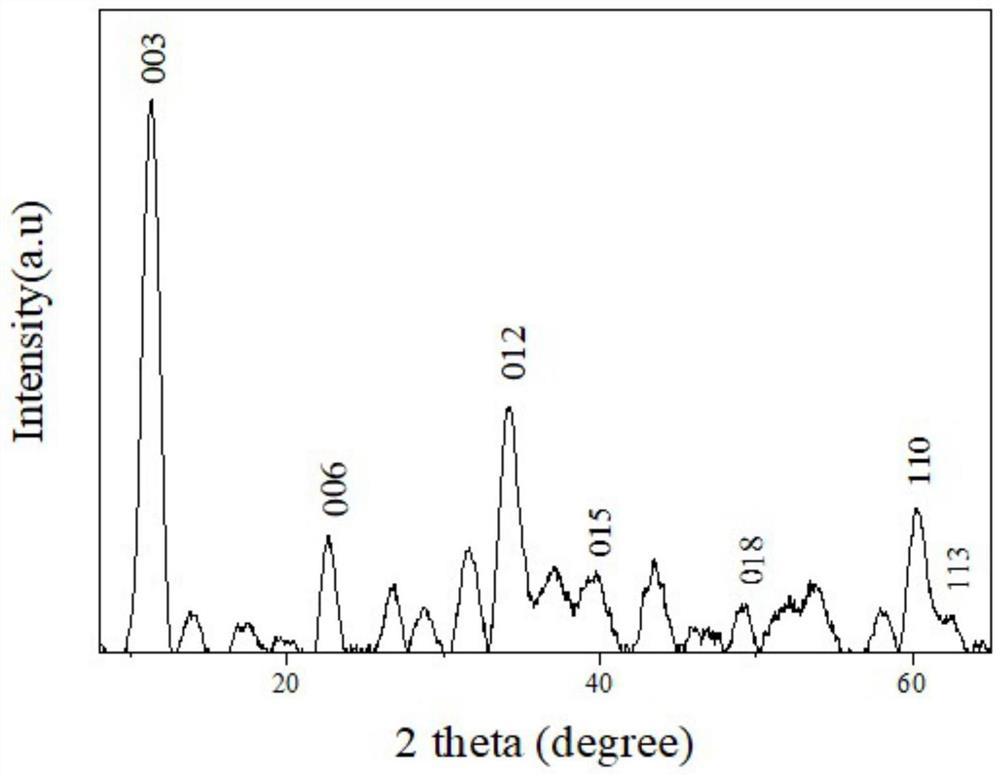

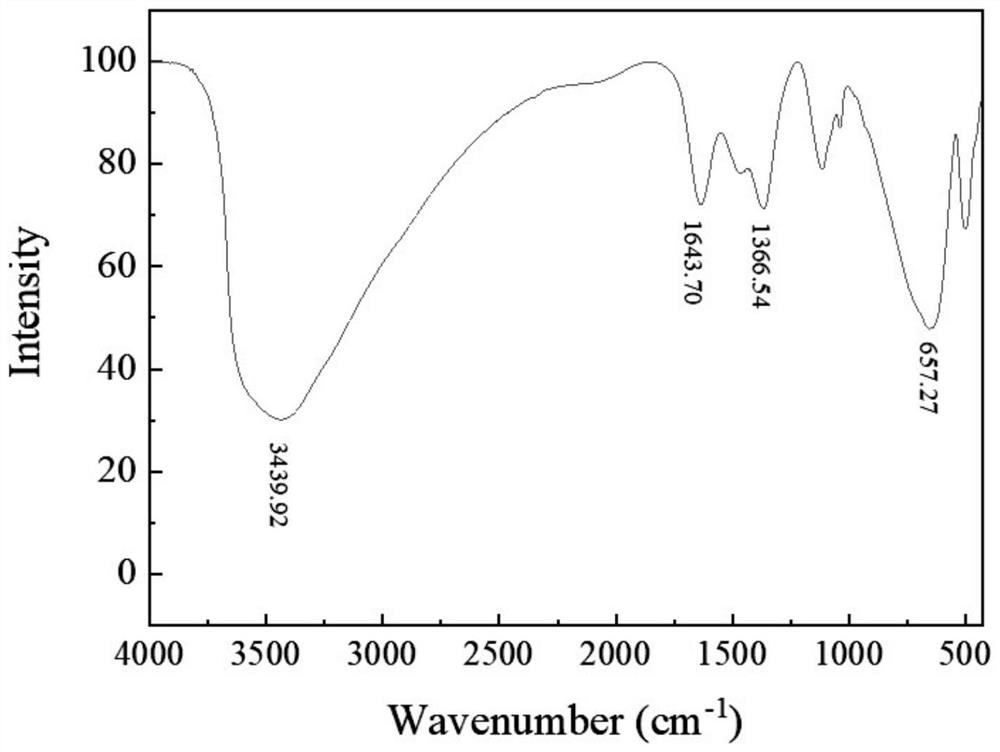

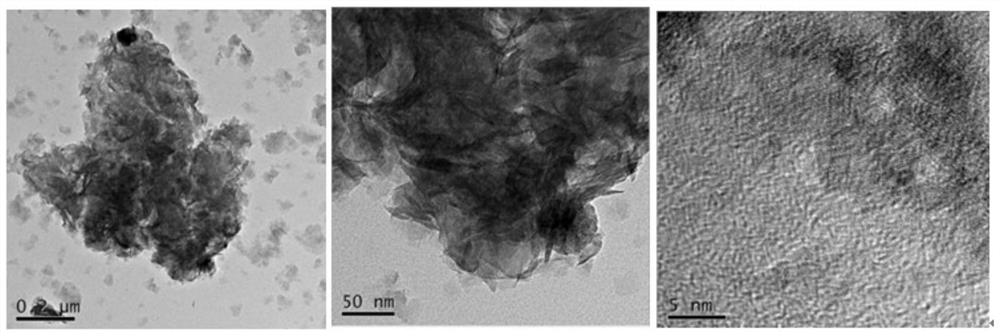

[0046] Embodiment 1: Preparation of CNF-LDHs

[0047] With a nickel-iron ratio of 4:1, 0.008 mol / L nickel chloride, or 1.9015 g, and 0.002 mol / L ferric chloride, or 0.5406 g, were dissolved in 10 mL of distilled water by heating and stirring at 60°C, and then ultrasonically dispersed and mixed for 20 minutes. Prepare a 1 mol / L sodium hydroxide solution, that is, dissolve 4 g of sodium hydroxide in 100 mL of distilled water and stir well. Under vigorous stirring at room temperature, the nickel-iron mixed salt solution and sodium hydroxide solution were slowly added dropwise into a beaker filled with 40 mL of distilled water. The nickel-iron mixed salt solution and sodium hydroxide solution use a peristaltic pump to control the dropping rate, and use it during the dropping process p H meter control reaction p The H value was stable at 10 until the end of the dropwise addition of the nickel-iron mixed salt solution, and the peristaltic pump was turned off. After continuing to ...

Embodiment 2

[0052] Embodiment 2: Preparation of CNF-LDHs

[0053] The ratio of nickel to iron is 3:1; used in the process of dropping p H meter control reaction p The H value was stable at 9; the microwave temperature was set at 120°C for 30 min, and the reaction was carried out.

[0054] Others are all the same as in Example 1.

Embodiment 3

[0055] Embodiment 3: the preparation of CNF-LDHs

[0056] The ratio of nickel to iron is 5:1; used in the process of dropping p H meter control reaction p The H value was stable at 11; the microwave temperature was set at 140°C for 45 min to carry out the reaction.

[0057] Others are all the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com