Preparation technology of ultrahigh-purity silicon carbide powder applied to field of semiconductors

A silicon carbide powder, silicon carbide technology, applied in carbon compounds, inorganic chemistry, nitrogen compounds, etc., can solve the problems of inability to guarantee the purity of raw materials, doubts about industrialization efficiency, and lack of introduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

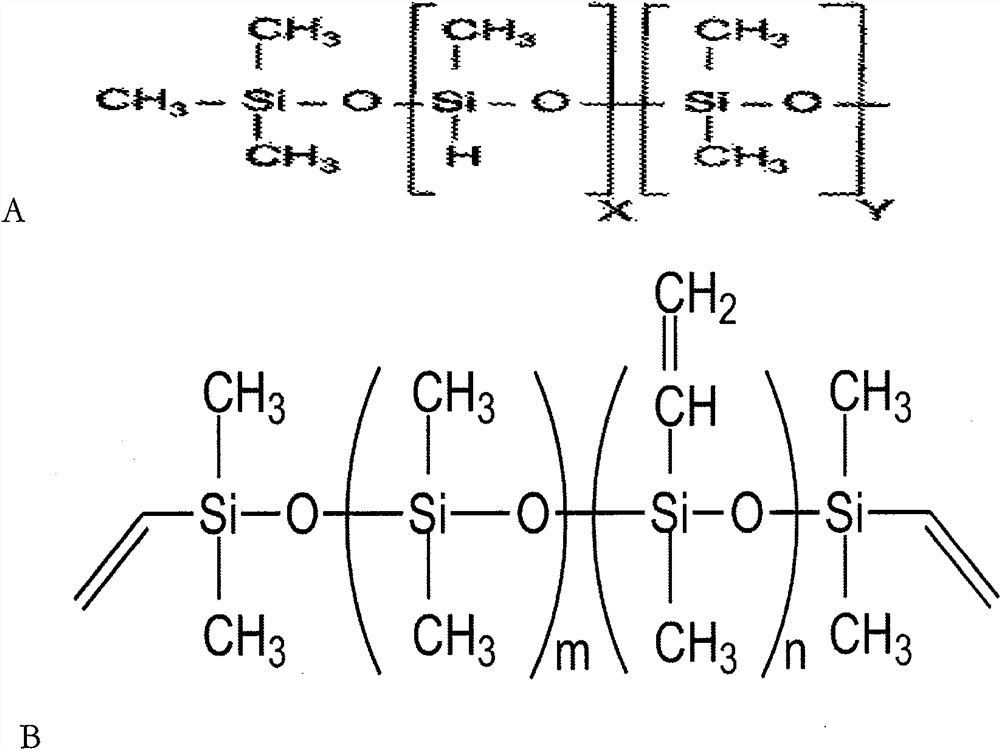

[0196]Formulation of silicon-carbon-containing polymer formulations using a hybrid approach. The formulation was prepared by mixing 41% MHF and 59% TV at room temperature. The precursor formulation has 0.68 moles of hydrogen, 0.68 moles of vinyl and 1.37 moles of methyl groups. The precursor formulation has the following molar amounts of Si, C and O based on 100 g of formulation.

[0197] According to calculations, the SiOC derived from the formulation had a calculated 1.37 moles of C with 0% excess C after all CO had been removed.

Embodiment 2

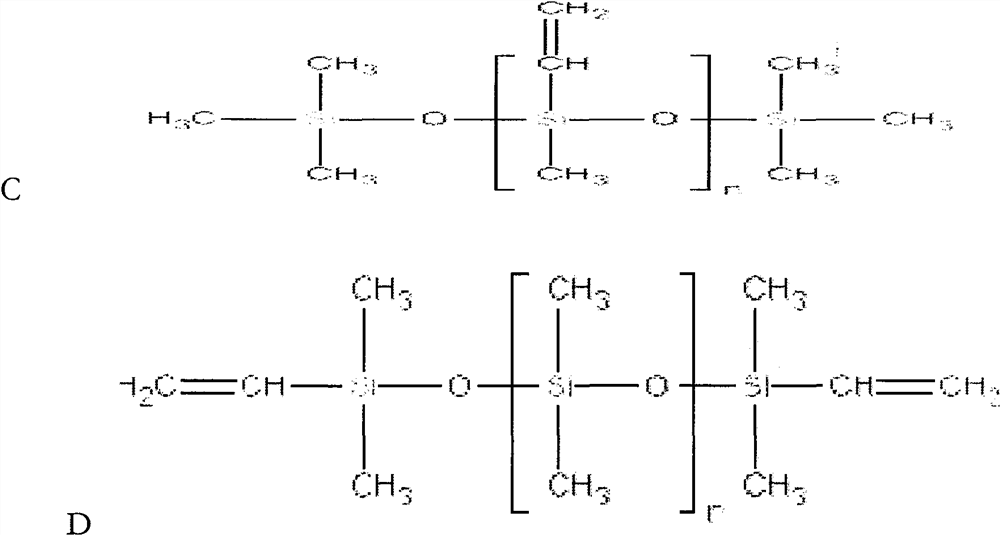

[0199] Formulation of silicon-carbon-containing polymer formulations using a hybrid approach. The formulation was prepared by mixing 90% methyl terminated phenylethyl polyoxysilane (with 27% X) and 10% TV at room temperature. The precursor formulation has 1.05 moles of hydrogen, 0.38 moles of vinyl, 0.26 moles of phenyl and 1.17 moles of methyl groups. Based on 100 g of formulation, the precursor formulation has the following molar amounts of SiSO. According to calculations, the SiOC derived from the formulation, after all CO has been removed, will have a calculated 2.31 moles of C with a 98% excess of C .

Embodiment 3

[0201] Formulation of silicon-carbon-containing polymer formulations using a hybrid approach. The formulation was prepared by mixing 70% methyl terminated phenylethyl polyoxysilane (with 14% X) and 30% TV at room temperature. The precursor formulation has 0.93 moles hydrogen, 0.48 moles vinyl, 0.13 moles phenyl and 1.28 moles methyl. Based on 100 g of formulation, the precursor formulation has the following molar amounts of Si, C, O; it is calculated that the SiOC derived from the formulation, after all CO has been removed, will have a calculated 1.77 moles of C and have 38% excess C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com