Preparation method for crystal modification in synthesis of basic copper chloride

A technology of copper chloride and crystal, which is applied in the field of preparation of crystal modification, can solve the problems of difficult control, high production cost, complex reaction, etc., and achieve the effects of increasing moisture resistance, short synthesis time, and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A preparation method for crystal modification in basic copper chloride synthesis, comprising the steps of:

[0037] At room temperature, add copper chloride to the reaction kettle, then add tap water, and stir thoroughly until the copper chloride is completely dissolved;

[0038] Then add the polymer crystal improver to the reaction kettle, and continue to stir after adding;

[0039] Then add sodium hydroxide solution, continue to stir after adding, then leave standstill;

[0040] Afterwards, open the bottom of the reaction kettle and transfer to a vacuum filtration device for suction filtration. After the solid is obtained, it is washed with tap water. After the suction filtration is completed, it is placed in a drying oven to dry at a constant temperature;

[0041] Then take the dried obtained product and carry out a simulated high temperature and high humidity test in a constant temperature and humidity test chamber.

[0042] Add industrial-grade solid copper chlor...

Embodiment 1

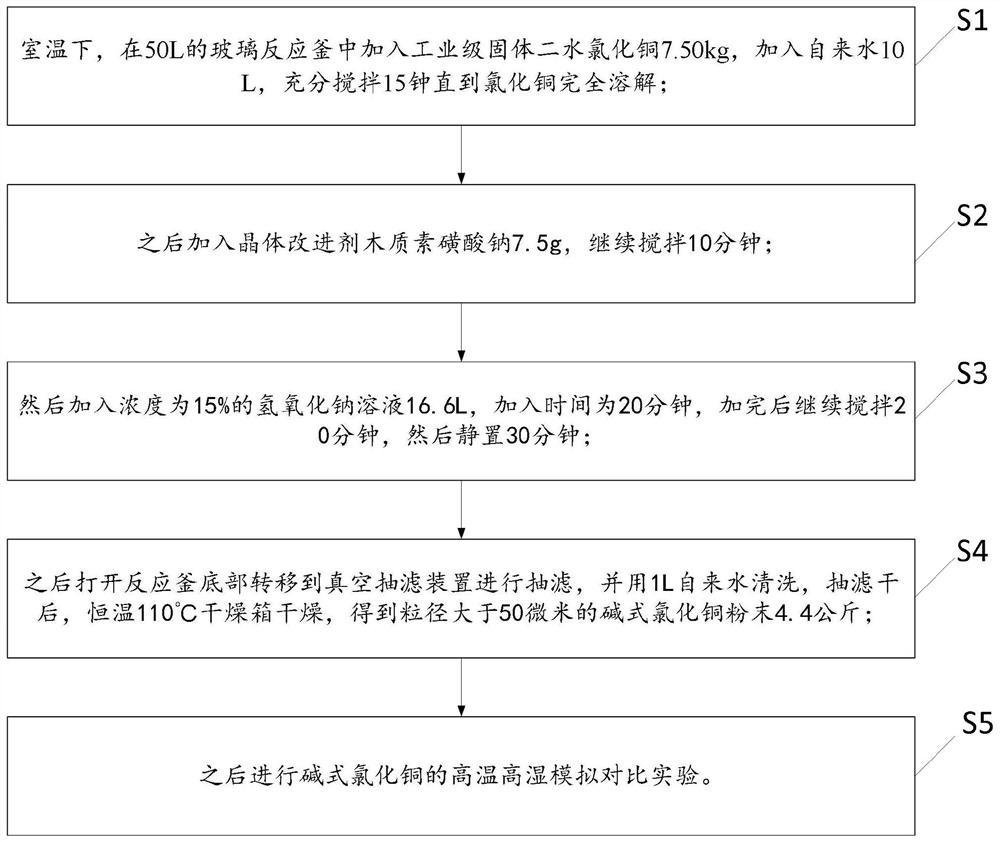

[0060] Example 1, see figure 1 , the invention provides a kind of preparation method of the crystal modification in the synthesis of basic copper chloride, comprising the steps:

[0061] S1: At room temperature, add 7.50kg of industrial-grade solid copper chloride dihydrate into a 50L glass reactor, add 10L of tap water, and stir for 15 minutes until the copper chloride is completely dissolved;

[0062] S2: Then add 7.5 g of sodium lignosulfonate crystal modifier, and continue to stir for 10 minutes;

[0063] S3: Then add 16.6L of 15% sodium hydroxide solution for 20 minutes, continue to stir for 20 minutes after adding, and then let stand for 30 minutes;

[0064] S4: Open the bottom of the reaction kettle and transfer to a vacuum filtration device for suction filtration, and wash with 1L of tap water, after suction filtration, dry in a constant temperature 110°C drying oven to obtain 4.4 kg of basic copper chloride powder with a particle size greater than 50 microns;

[0065]...

Embodiment 2

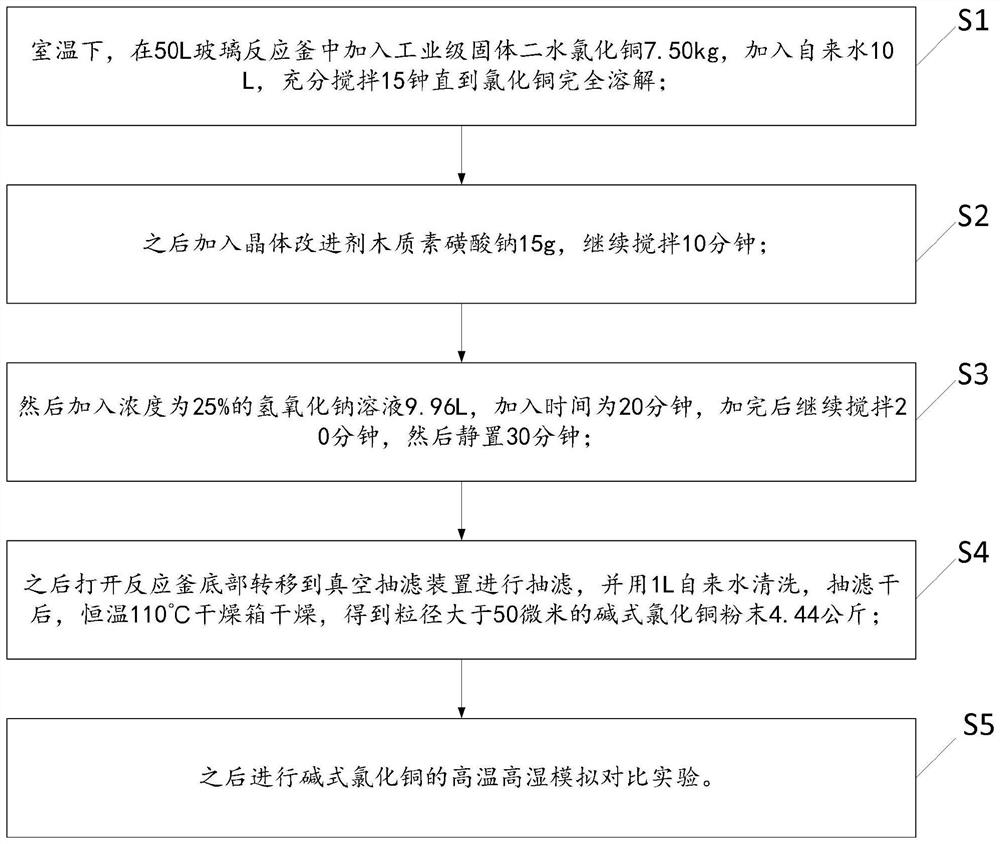

[0067] Example 2, see figure 2 , the invention provides a kind of preparation method of the crystal modification in the synthesis of basic copper chloride, comprising the steps:

[0068] S1: At room temperature, add 7.50kg of industrial-grade solid copper chloride dihydrate into a 50L glass reactor, add 10L of tap water, and stir for 15 minutes until the copper chloride is completely dissolved;

[0069] S2: Then add 15 g of sodium lignosulfonate, a crystal modifier, and continue stirring for 10 minutes;

[0070] S3: Then add 9.96L of 25% sodium hydroxide solution for 20 minutes, continue to stir for 20 minutes after the addition, and then let stand for 30 minutes;

[0071] S4: Open the bottom of the reaction kettle and transfer to a vacuum filtration device for suction filtration, and wash with 1L of tap water. After suction and drying, dry in a constant temperature 110°C drying oven to obtain 4.44 kg of basic copper chloride powder with a particle size greater than 50 micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com