Melamine composite material with low free formaldehyde content, preparation method thereof and melamine tableware

A technology of low free formaldehyde and composite materials, applied to melamine composite materials with low free formaldehyde content and its preparation, and in the field of melamine tableware, can solve problems such as endangering life and safety, reduce other side effects, and reduce the risk of tumor and cancer Prevalence, superior mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] The present invention also provides a method for preparing a melamine composite material with low free formaldehyde content, comprising the following steps:

[0058] Add 2,4,6-triaminopyrimidine powder to the formaldehyde solution for a synthesis reaction to generate melamine resin;

[0059] Process the melamine resin to obtain melamine powder;

[0060] The melamine powder is then copolymerized with the pentaerythritol to generate the melamine composite material;

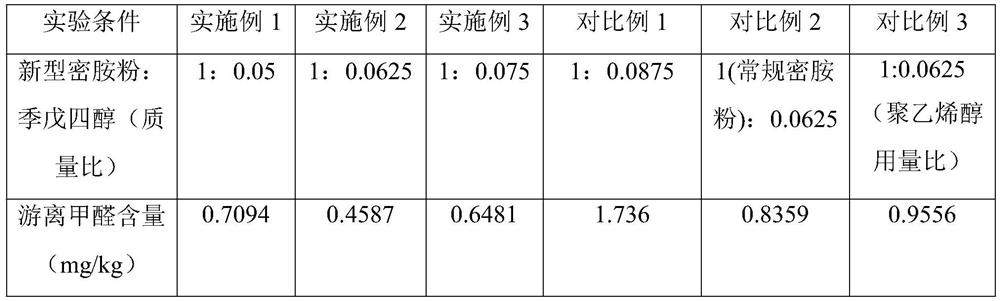

[0061] The molar ratio of the 2,4,6-triaminopyrimidine to formaldehyde is 1:3-1:2, and the mass ratio of the pentaerythritol to the melamine powder is 1:0.075-1:0.05.

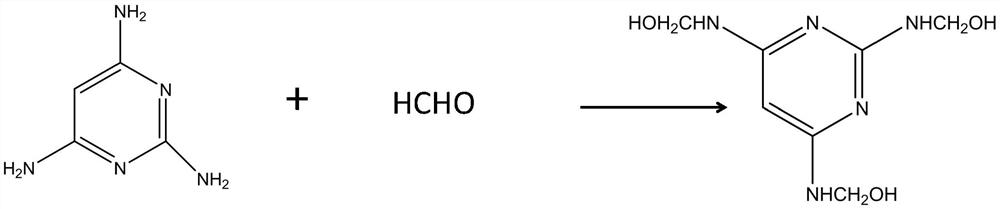

[0062] The chemical equation for the synthesis reaction of formaldehyde and 2,4,6-triaminopyrimidine is:

[0063]

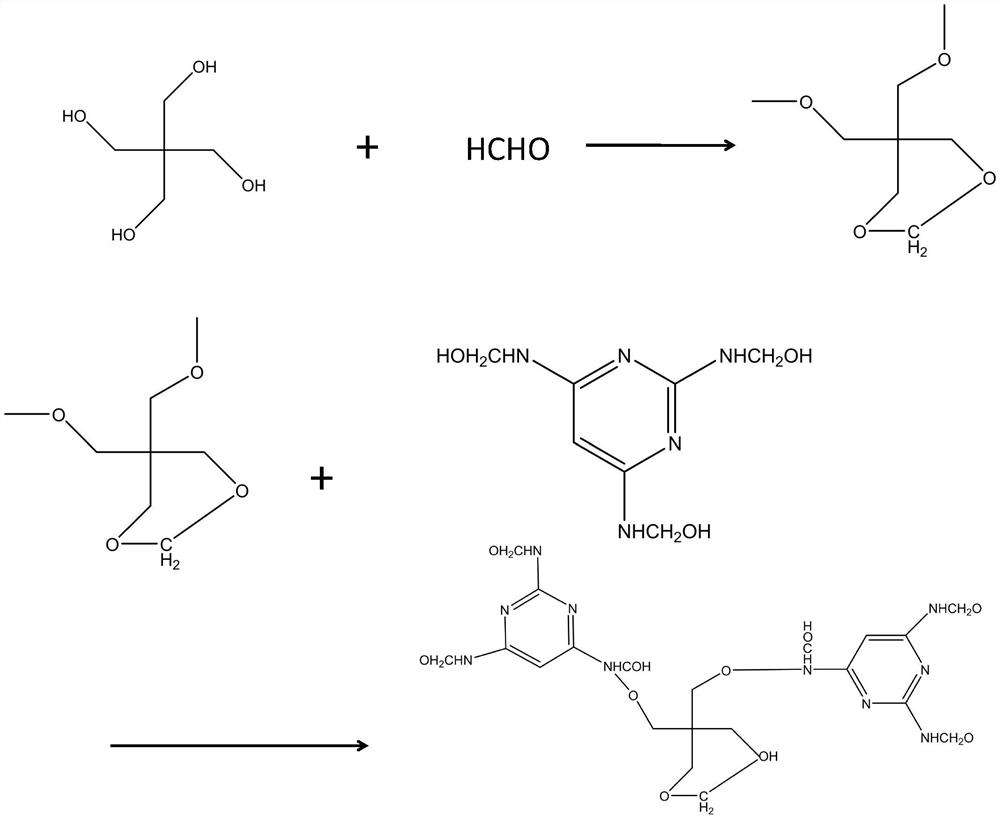

[0064] The chemical equation for the copolymerization of melamine powder and pentaerythritol is:

[0065]

[0066] The melamine composite material with low free formaldehyde content proposed according to the present inve...

Embodiment 1

[0083] In the present invention, 2,4,6-triaminopyrimidine and formaldehyde are synthesized to generate a novel melamine resin, and the novel melamine resin is processed to obtain a novel melamine powder, and then the melamine powder undergoes a copolymerization reaction with pentaerythritol to generate melamine composite material.

[0084] The steps of melamine powder preparation are as follows:

[0085] (1) According to the 1:2 molar ratio of 2,4,6-triaminopyrimidine to formaldehyde, add 106ml of formaldehyde solution into the three-necked flask, and adjust its pH to 9 with 30% NaOH solution.

[0086] (2) Add 2,4,6-triaminopyrimidine powder into the pH-adjusted formaldehyde solution, place it in a water bath heated to 86°C in advance, and control the temperature of the water bath when the white milky liquid in the flask becomes clear and transparent After 2 hours of reaction, triethanolamine was added to terminate the reaction.

[0087] (3) Take out the product at 76°C, put...

Embodiment 2

[0092] In the present invention, 2,4,6-triaminopyrimidine and formaldehyde are synthesized to generate a novel melamine resin, and the novel melamine resin is processed to obtain a novel melamine powder, and then the melamine powder undergoes a copolymerization reaction with pentaerythritol to generate melamine composite material. The steps of melamine powder preparation are as follows:

[0093] (1) According to the molar ratio of 2,4,6-triaminopyrimidine to formaldehyde of 5:12, add 106ml of formaldehyde solution into the three-necked flask, and adjust its pH to 8.5 with 30% NaOH solution.

[0094] (2) Add 2,4,6-triaminopyrimidine powder to the pH-adjusted formaldehyde solution, place it in a water bath heated to 90°C in advance, and control the temperature of the water bath when the white milky liquid in the flask becomes clear and transparent After 2 hours of reaction at 80°C, triethanolamine was added to terminate the reaction.

[0095] (3) Take out the product at 82°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com