Self-crosslinking fog sealing material based on cationic water-based acrylic acid as well as preparation method and application of self-crosslinking fog sealing material

A water-based acrylic and cationic technology, applied in building thermal insulation materials, building components, buildings, etc., to achieve the effects of low input cost, excellent performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

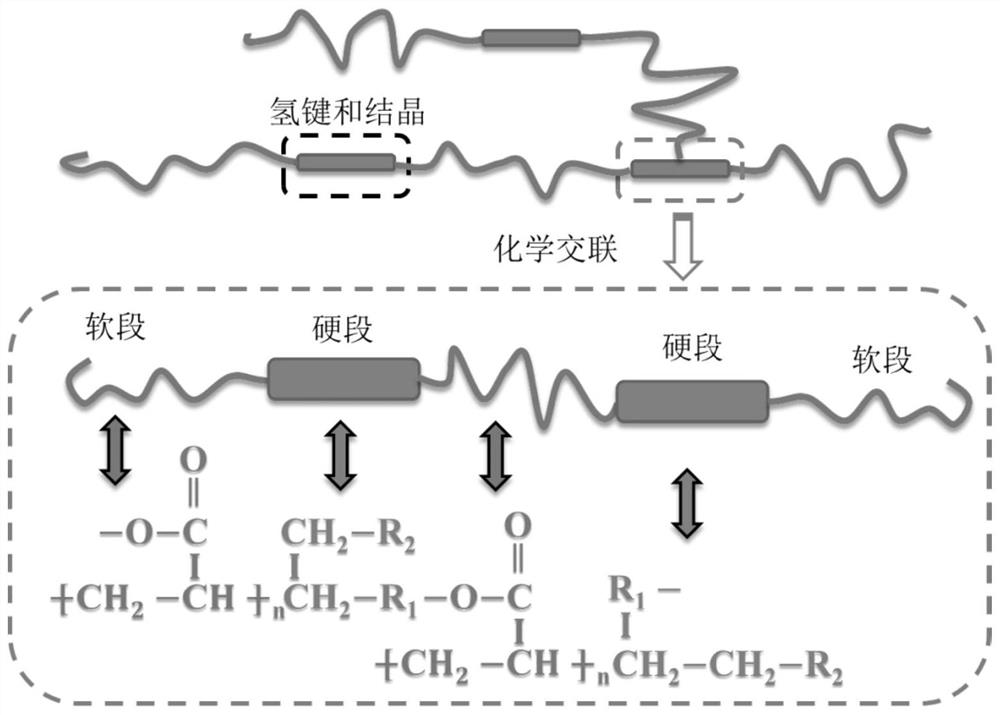

Method used

Image

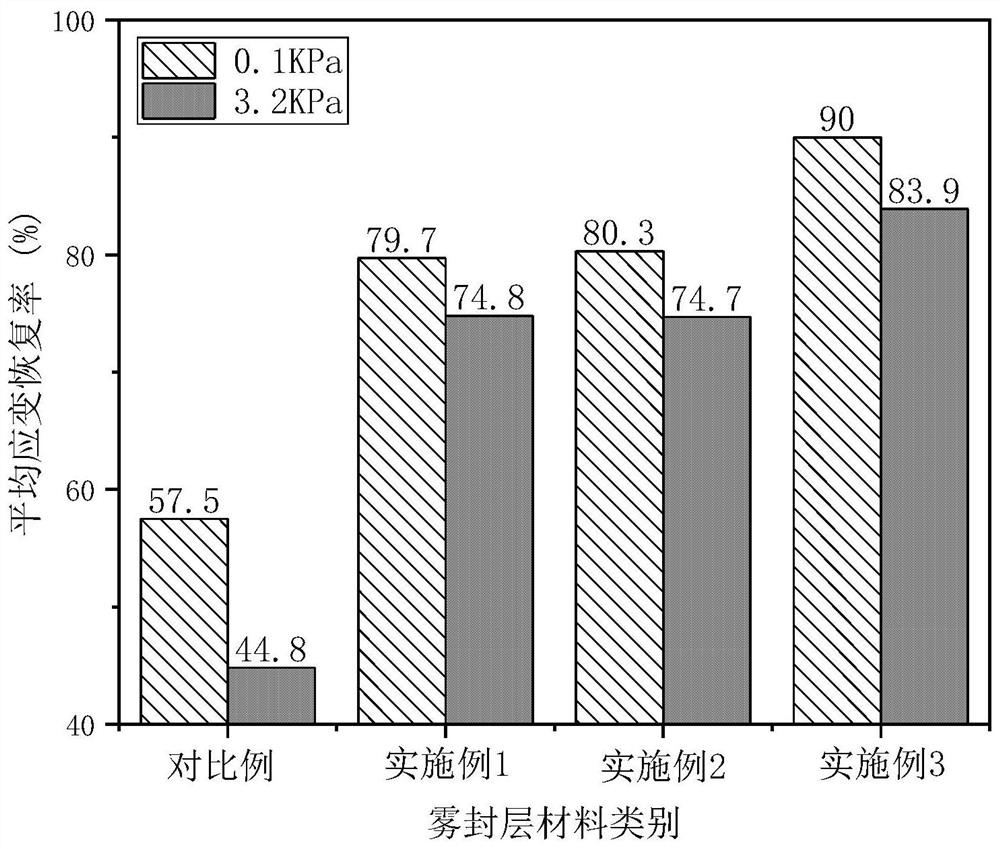

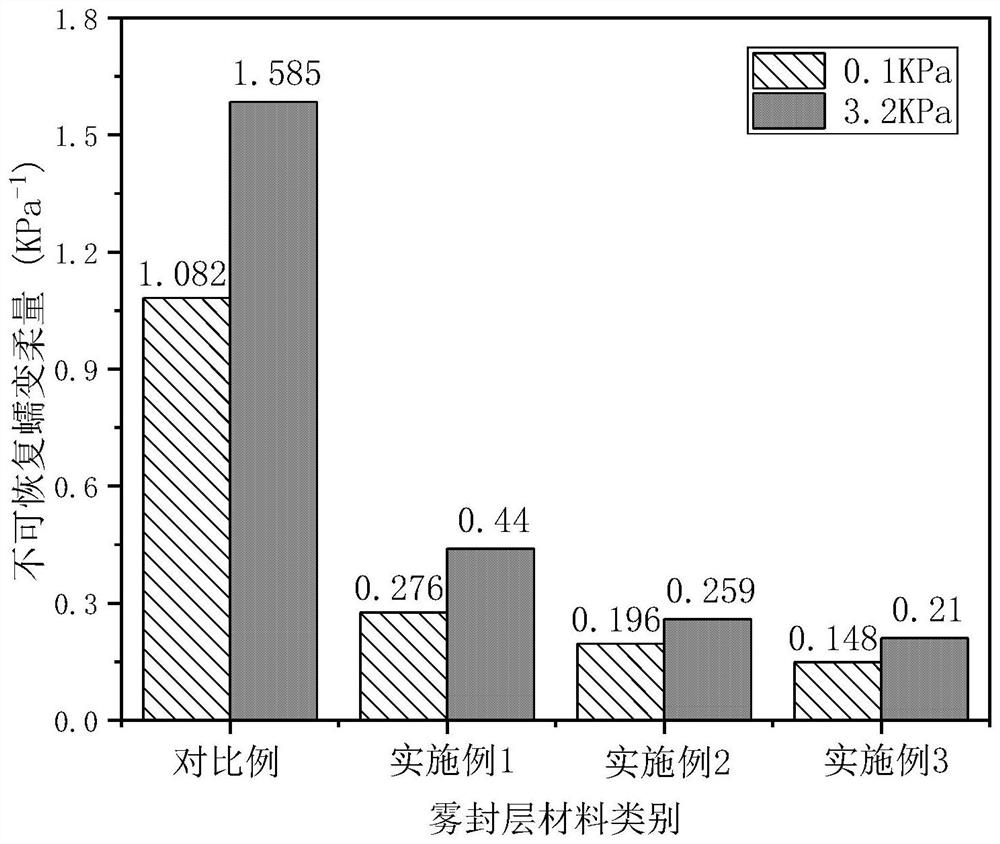

Examples

Embodiment 1

[0057] The preparation method and application, in specific implementation, include the following steps:

[0058] (1) Weigh by mass, mix and stir 45 parts of deionized water, 2.5 parts of cetyltrimethylammonium bromide cationic emulsifier and 4 parts of chlorine salt additive, slowly add hydrochloric acid, adjust the pH value of the solution to 2.2, and then heated to 60°C to prepare soap liquid;

[0059] (2) Heat 55 parts of 70# base asphalt to 180°C, shear with 2.0 parts of styrene-butadiene-styrene block copolymer at high speed for 1 hour, and develop at 170°C for 1 hour to prepare SBS modified Sexual asphalt. Then stir and mix with 45 parts of soap liquid, and slowly pour into the colloid mill. The colloid mill was preheated to 120°C, and the emulsion was left to stand in the heat exchanger for 1 hour to prepare the SBS modified asphalt emulsion;

[0060] (3) Weigh in parts by mass, add 100 parts of methyl acrylate into a 250ml three-necked flask, and carry out a constan...

Embodiment 2

[0069] The preparation method and application, in specific implementation, include the following steps:

[0070] (1) Weigh by mass, mix and stir 37 parts of deionized water, 2.5 parts of cetylpyridinium bromide cationic emulsifier and 2.5 parts of chloride salt additive, slowly add hydrochloric acid, adjust the pH value of the solution to 2.1, Then heated to 65°C to prepare soap liquid;

[0071] (2) Heat 55 parts of 70# base asphalt to 170°C, shear with 3 parts of styrene-butadiene-styrene block copolymer at high speed for 1 hour, and develop at 160°C for 1.5 hours to prepare SBS modified asphalt. Then stir and mix with 38 parts of soap liquid, and slowly pour into the colloid mill. The colloid mill was preheated to 110°C, and the emulsion was left to stand in the heat exchanger for 2 hours to prepare SBS modified emulsified asphalt;

[0072] (3) Weigh in parts by mass, add 95 parts of 2-methyl methacrylate into a 250ml three-necked flask, and conduct a constant temperature...

Embodiment 3

[0077] The preparation method and application, in specific implementation, include the following steps:

[0078] (1) Weigh by mass, mix and stir 43 parts of deionized water, 3.0 parts of cetylpyridinium bromide cationic emulsifier and 3.5 parts of chloride salt additive, slowly add hydrochloric acid, adjust the pH value of the solution to 1.9, Then heated to 65°C to prepare soap liquid;

[0079] (2) Heat 63 parts of 70# base asphalt to 175°C, shear it with 2.8 parts of styrene-butadiene-styrene block copolymer at high speed for 1 hour, and develop it at 170°C for 1.5 hours to prepare SBS modified asphalt. Then stir and mix with 43 parts of soap liquid, and slowly pour into the colloid mill. The colloid mill was preheated to 110°C, and the emulsion was left to stand in the heat exchanger for 1.5 hours to prepare SBS modified emulsified asphalt;

[0080] (3) Weigh in parts by mass, add 94 parts of 2-ethyl methacrylate into a 250ml three-necked flask, and conduct a constant temp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap