Preparation method of composite material serpentine spring

A serpentine spring and composite material technology, applied in the spring field, achieves the effect of safe and reliable work, environmental protection price, and high specific modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

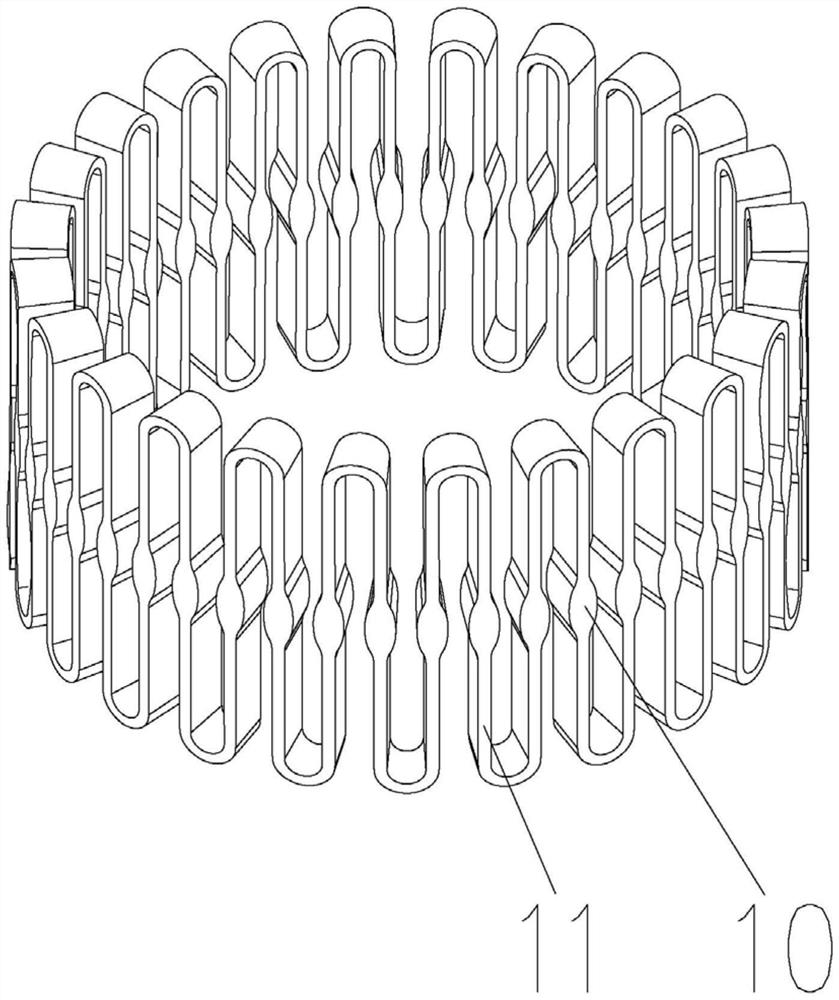

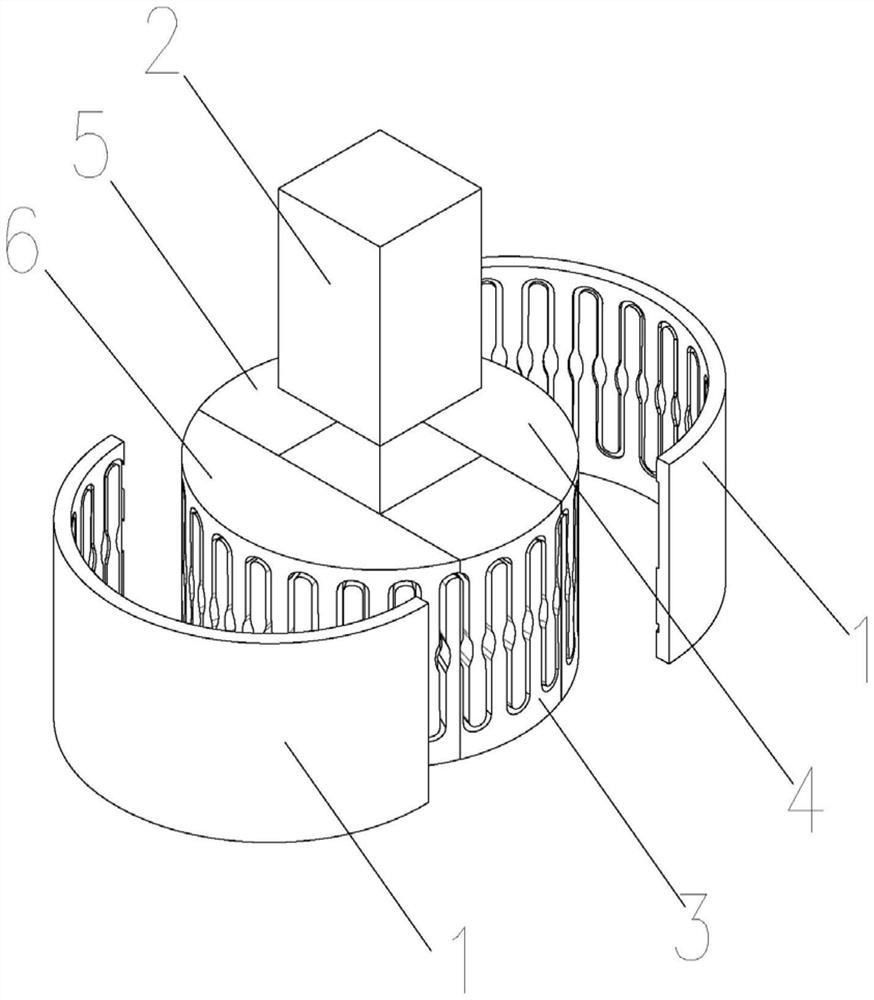

[0027] Please refer to the attached figure 1 to attach Figure 4 Shown, the present invention is a kind of preparation method of composite serpentine spring, and it comprises following processing step:

[0028] 1), material selection: select basalt unidirectional cloth and resin for backup.

[0029] Wherein, the selected basalt unidirectional cloth can be replaced by glass fiber unidirectional cloth. The resin adopts toughened epoxy resin, polyurethane resin, or resin suitable for molding, pultrusion or RTM process. This type of resin has the characteristics of long curing cycle, and then reserves a long enough time for various operations in the preparation process. .

[0030] Further, the basalt unidirectional fabric and resin can also be directly replaced with basalt fiber unidirectional fabric prepreg.

[0031] 2) Prepare the preform: first, cut the basalt fiber unidirectional cloth into a shape suitable for the designed composite serpentine spring dimensional character...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com