Novel capillary fiber grating and preparation method thereof

A fiber grating and capillary technology, applied in cladding fibers, optical waveguides, light guides, etc., can solve the problems of difficult operation, reduced mechanical strength, poor anti-interference ability, etc., and achieve stable spectral characteristics, low insertion loss, and high stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

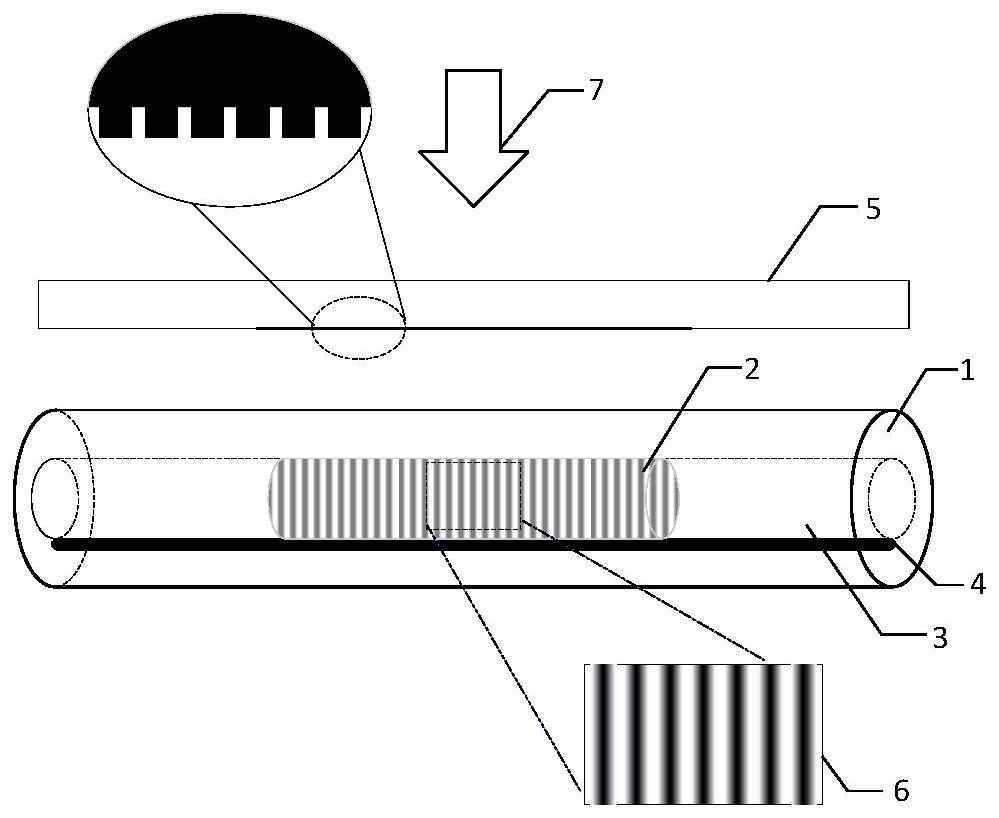

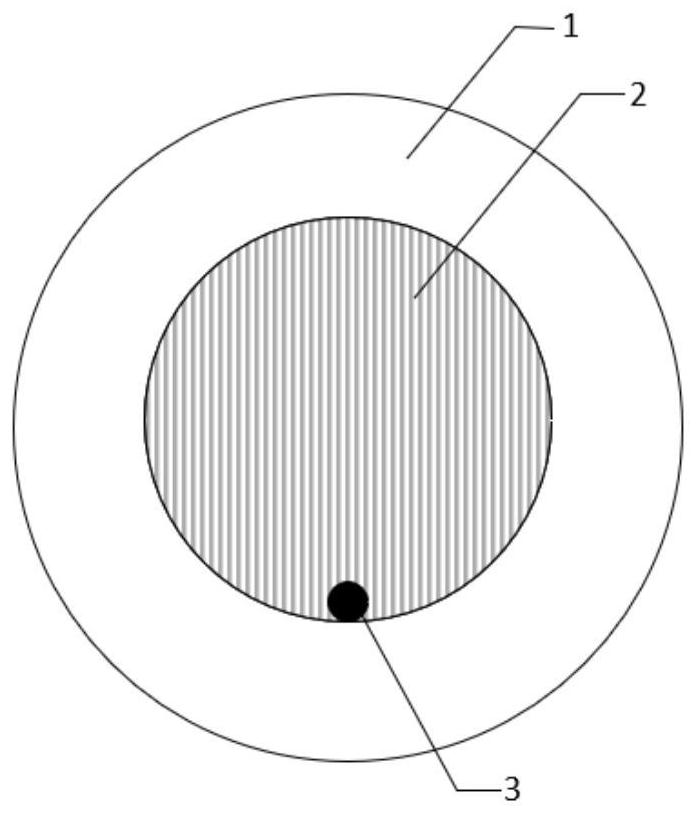

[0035] Such as figure 1 Shown is the preparation process of capillary fiber grating prepared by ultraviolet exposure method, including four-layer structure: optical fiber annular cladding, photosensitive resin cladding, inner wall grating, and optical fiber core. The photosensitive resin cladding is located at the central air hole, the fiber core is located in the annular cladding, and the grating is written on the photosensitive resin cladding. The preparation of capillary fiber grating by ultraviolet exposure method includes the following steps:

[0036] Step 1.1: Heat and break the capillary to form a tapered tip with a diameter of about 2 microns. Use a precision electric shift platform to align the capillary filled with photosensitive resin material with the air hole cladding of the capillary fiber, pressurize the syringe, and make the photosensitive resin material fill the air hole in the central air hole of the capillary fiber in Figure 2 (a) to form a photosensitive r...

Embodiment 2

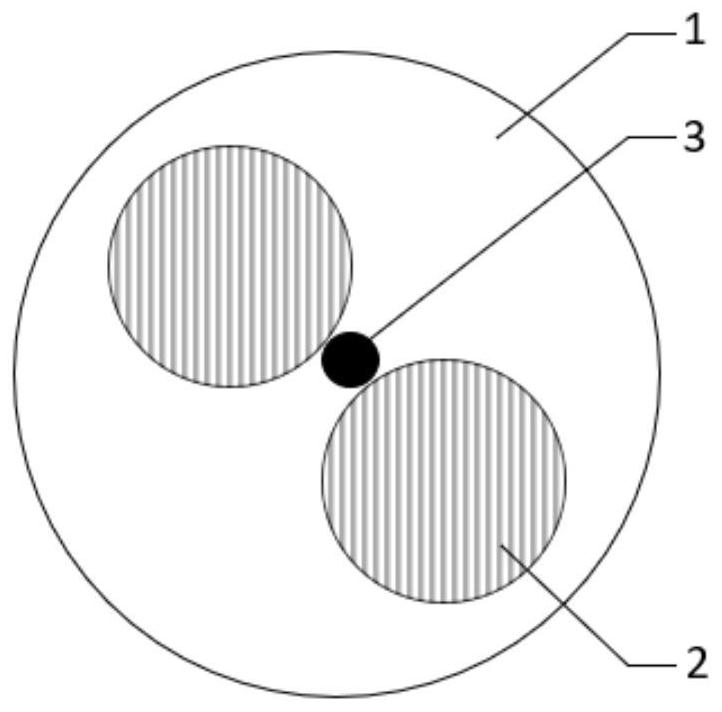

[0043] Experimental device such as figure 1 As shown in Figure 2(b), the scheme of the dual-hole capillary fiber grating prepared by ultraviolet exposure method, the core is located in the center, and two air holes are placed on both sides of the core and distributed symmetrically, each air hole is responsible for a grating array. Concrete preparation method is as follows:

[0044] Step 2.1: Heat and break the capillary to form a tapered tip with a diameter of about 2 microns. Use a precision electric shift platform to align the capillary filled with photosensitive resin material with the air hole cladding of the capillary fiber, pressurize the syringe, and make the photosensitive resin material fill the air hole in the central air hole of the capillary fiber in Figure 2 (b) to form a photosensitive resin cladding;

[0045] Step 2.2: Cut the two ends of the double-bore capillary optical fiber flat with a cutting machine, and fix them on the glass slide. One end is connected ...

Embodiment 3

[0050] As shown in Figure 2(c), it is a schematic diagram of a capillary fiber grating prepared by ultraviolet exposure in a suspended core capillary fiber, wherein the core is located in the fiber cladding, and the grating is located in the photosensitive resin cladding, bound by the photosensitive resin material, The air hole is located at the center. The preparation method comprises the following steps:

[0051] Step 3.1: Heat and break the capillary to form a tapered tip with a diameter of about 2 microns. Use a precision electric displacement platform to align the capillary filled with photosensitive resin material with the air hole cladding of the capillary fiber, pressurize the syringe, and make the photosensitive resin material fill the air hole in the central air hole of the capillary fiber in Figure 2 (c) to form a photosensitive resin cladding;

[0052] Step 3.2: Cut the two ends of the suspended core capillary fiber respectively with a cutting machine and fix them...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com