A kind of polyacrylonitrile fiber with biological activity and preparation method thereof

A polyacrylonitrile fiber, bioactive technology, applied in fiber processing, fiber type, textile and papermaking, etc., can solve the limited effect of modified polyacrylonitrile fiber biocompatibility and increase the risk of implant-related complications , limit the application value of modified polyacrylonitrile fibers, etc., to achieve the effect of stable and efficient reaction system, conducive to directional growth and functional expression, and reducing the residue of toxic substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

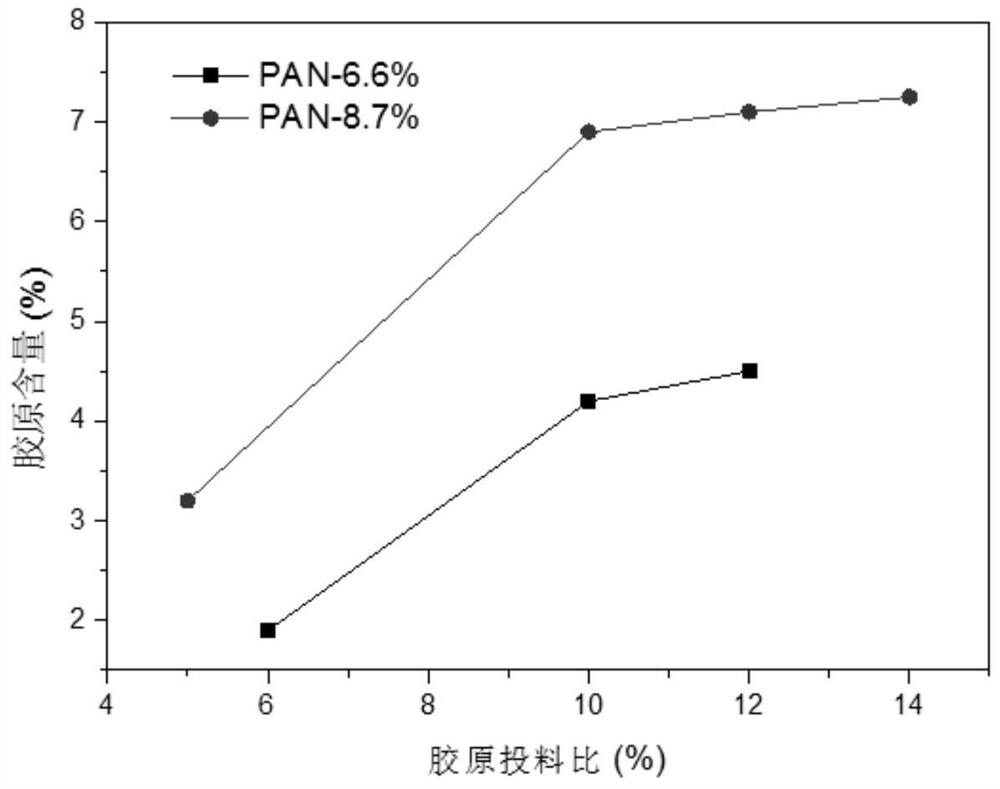

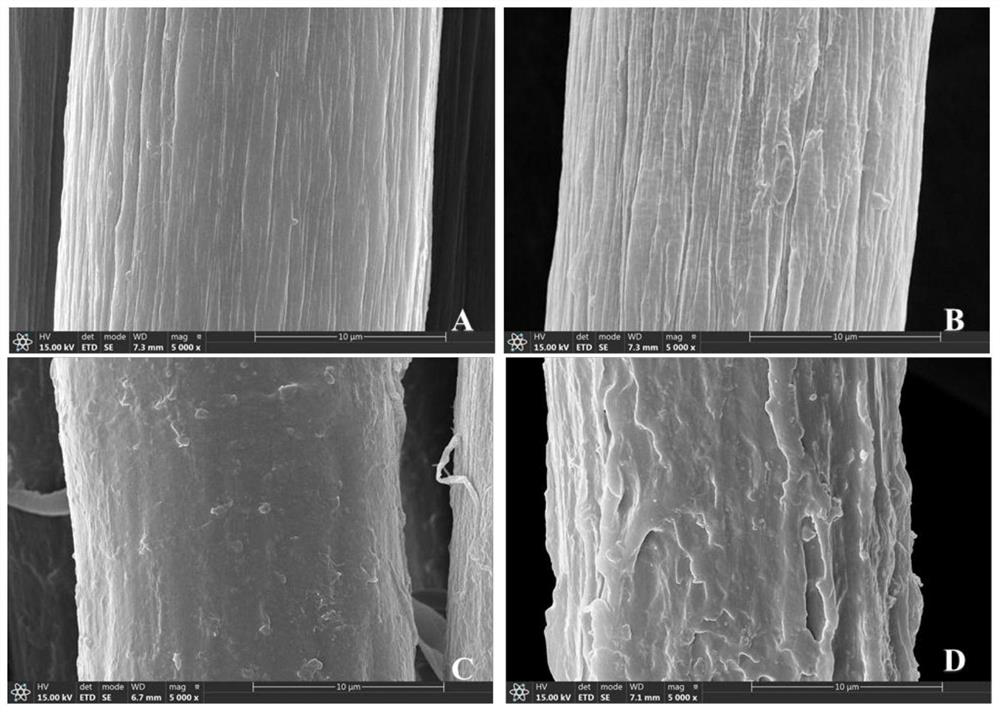

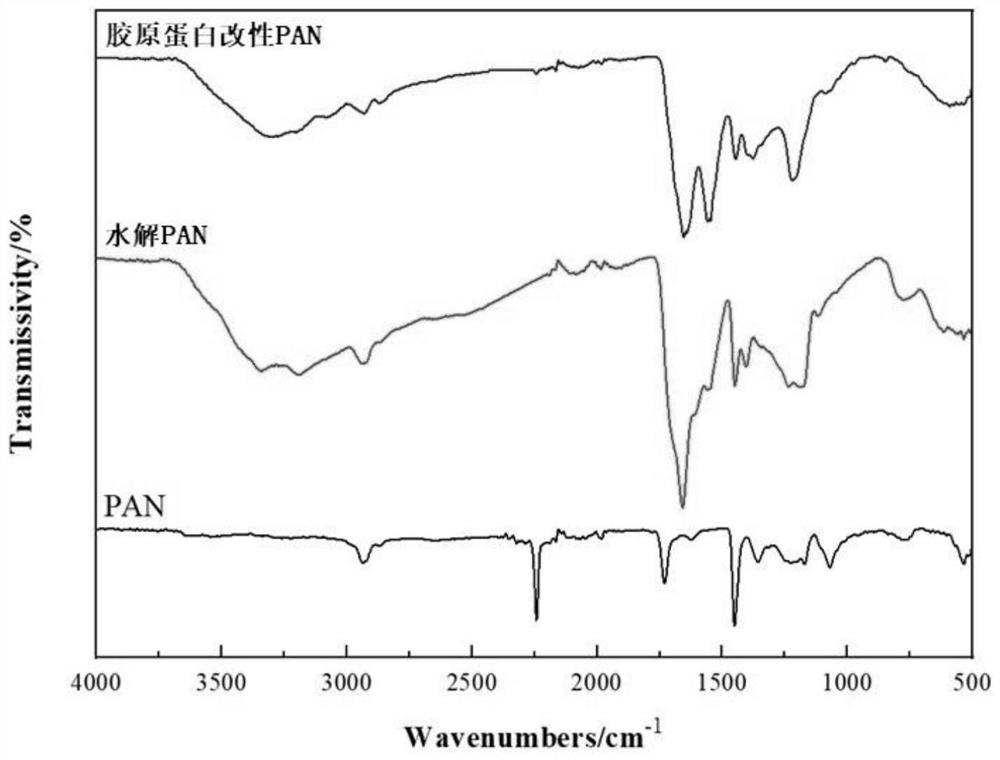

[0048] (1) With polyacrylonitrile (PAN) fiber: NaOH: NaHCO 3 =3:0.7:0.3 mass ratio to weigh PAN fiber, NaOH and NaHCO respectively 3 , weigh 3g of PAN fibers with a linear density of 2.22 to 5.55dtex and place them in a 500mL three-necked flask, weigh 0.7g of NaOH and 0.3g of NaHCO 3 Prepare an alkaline solution with a concentration of 1%, add it into a three-necked flask equipped with PAN fiber, start the stirrer, select a stirring speed of 60-100 r / min, heat up to 85-95 ° C, and condense and reflux for 48-72 h, so that After the reaction is completed, the sample is cooled to room temperature, washed with a large amount of water, acidified with a hydrochloric acid solution, washed with a large amount of water, and freeze-dried to obtain a hydrolyzed PAN fiber sample.

[0049] (2) The Na 2 HPO 4 ·2H 2 O, NaH 2 PO 4 , 1-(3-Dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC), N-hydroxysuccinimide (NHS) dissolved in water at 20℃~25℃ Mix well, the concentration of ...

Embodiment 2

[0052] (1) With polyacrylonitrile (PAN) fiber: NaOH: NaHCO 3 =3:0.7:0.3 mass ratio to weigh PAN fiber, NaOH and NaHCO respectively 3 , weigh 3g of PAN fibers with a linear density of 2.22 to 5.55dtex and place them in a 500mL three-necked flask, weigh 0.7g of NaOH and 0.3g of NaHCO 3 Prepare an alkaline solution with a concentration of 1%, add it into a three-necked flask equipped with PAN fiber, start the stirrer, select a stirring speed of 60-100 r / min, heat up to 85-95 ° C, and condense and reflux for 48-72 h, so that After the reaction is completed, the sample is cooled to room temperature, washed with a large amount of water, acidified with a hydrochloric acid solution, washed with a large amount of water, and freeze-dried to obtain a hydrolyzed PAN fiber sample.

[0053] (2) The Na 2 HPO 4 ·2H 2 O, NaH 2 PO 4 , 1-(3-Dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC), N-hydroxysuccinimide (NHS) dissolved in water at 20℃~25℃ Mix well, the concentration of ...

Embodiment 3

[0056] (1) With polyacrylonitrile (PAN) fiber: NaOH: NaHCO 3 =3:0.7:0.3 mass ratio to weigh PAN fiber, NaOH and NaHCO respectively 3 , weigh 3g of PAN fibers with a linear density of 2.22 to 5.55dtex and place them in a 500mL three-necked flask, weigh 0.7g of NaOH and 0.3g of NaHCO 3 Prepare an alkaline solution with a concentration of 1%, add it into a three-necked flask equipped with PAN fiber, start the stirrer, select a stirring speed of 60-100 r / min, heat up to 85-95 ° C, and condense and reflux for 48-72 h, so that After the reaction is completed, the sample is cooled to room temperature, washed with a large amount of water, acidified with a hydrochloric acid solution, washed with a large amount of water, and freeze-dried to obtain a hydrolyzed PAN fiber sample.

[0057] (2) The Na 2 HPO 4 ·2H 2 O, NaH 2 PO 4 , 1-(3-Dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC), N-hydroxysuccinimide (NHS) dissolved in water at 20℃~25℃ Mix well, the concentration of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com