Nitrogen-sulfur double-doped porous carbon material catalyst and preparation method thereof

A porous carbon material, double-doped technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low doping amount, small specific surface area of catalyst, etc., and achieve simple preparation process , Ease of large-scale production, and the effect of improving degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

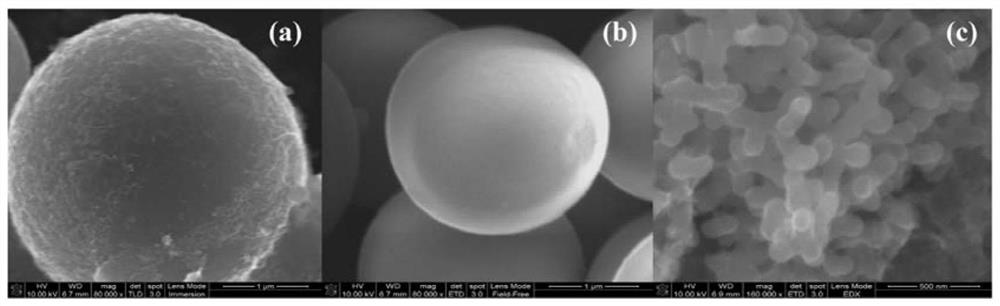

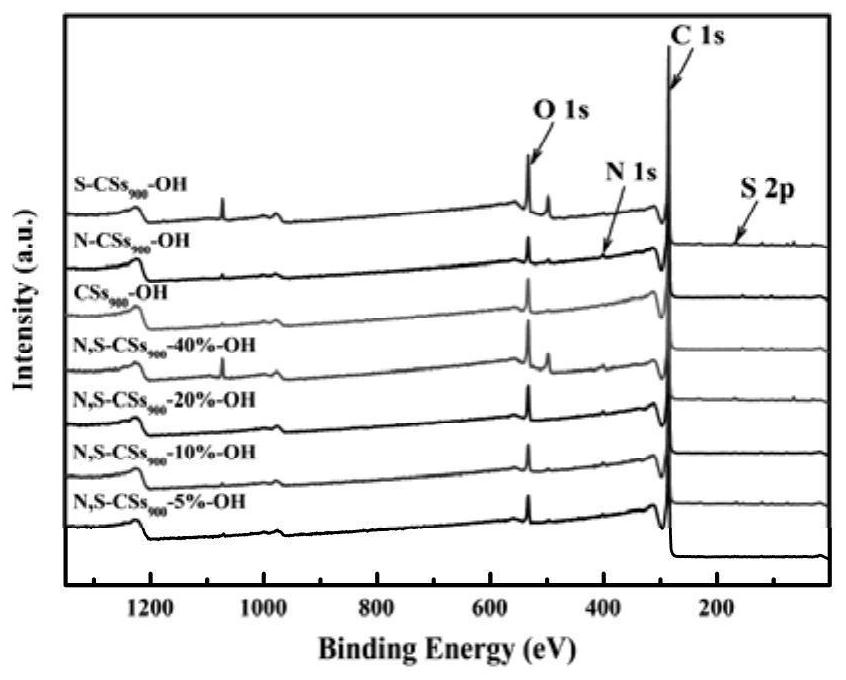

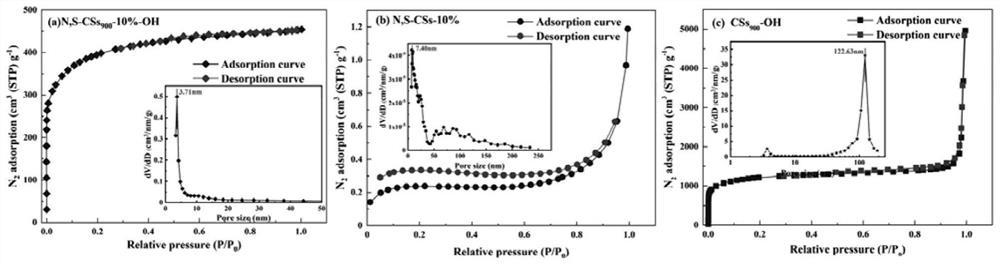

[0040] A nitrogen-sulfur double-doped porous carbon material catalyst in this embodiment, the porous carbon material includes a nitrogen-sulfur source and a carbon source with a mass ratio of 1% to 50%, the carbon source is glucose, and the nitrogen The sulfur source is cysteine, and its raw material is green and pollution-free, easy to purchase, and low in cost; the specific surface area of the nitrogen-sulfur double-doped porous carbon material is 1000-2000m 2 / g, it provides abundant active sites for the adsorption and degradation of biological organic pollutants, which is beneficial to improve the catalytic activity of the catalyst; the nitrogen element is covalently bonded to the carbon in the porous carbon material by pyrrole nitrogen, pyridine nitrogen and graphite nitrogen, Sulfur is covalently bonded to carbon in porous carbon materials in the form of thiophene sulfur (C-S-C) and sulfur oxide (C-SOX-C). The co-doping of nitrogen and sulfur not only ensures the catal...

Embodiment 2

[0045] A nitrogen-sulfur double-doped porous carbon material catalyst in this embodiment has the same basic structure as that in Example 1, the difference and improvement are that the nitrogen and sulfur elements are evenly distributed on the surface of the porous carbon material, and the pore diameter of the porous carbon material is The nitrogen-sulfur double-doped porous carbon material is in the shape of black powder. Compared with the undoped porous carbon material (large pores, the pore diameter is 122nm), the nitrogen-sulfur double-doped porous carbon material has more The rich pore structure provides more adsorption and reactive sites and electron migration channels for the adsorption and degradation of antibiotics and other organic substances, thereby improving the degradation efficiency of antibiotics and other organic substances.

Embodiment 3

[0047] The preparation method of a nitrogen-sulfur double-doped porous carbon material catalyst in this embodiment has the same basic structure as that in Embodiment 2, the difference and improvement are that it includes the following steps:

[0048] Step 1: Weigh a certain amount of carbon source, nitrogen source and sulfur source, mix and disperse in the aqueous solution, then transfer to the hydrothermal reactor container, raise to a certain temperature and keep it for a certain time to obtain the carbon, nitrogen, sulfur carbon materials;

[0049] Step 2. Put the synthesized carbon material containing carbon, nitrogen, and sulfur into a quartz glass container, pass in an inert gas as a protective gas, calcinate at high temperature for a certain period of time, and grind and pulverize after natural cooling to obtain a nitrogen-sulfur double-doped carbonized material;

[0050] Step 3. Put the synthesized nitrogen-sulfur double-doped carbonized material into a custom-made cru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com