A kind of heat-resistant heat-sensitive medical film and preparation method thereof

A high-temperature-resistant, heat-sensitive technology, applied in the field of heat-sensitive printing materials, can solve the problems of high surface friction resistance, affecting the color development of the imaging layer, poor high-temperature resistance, etc., and achieves increased mass transfer resistance and good scratch resistance. , Improve the effect of waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

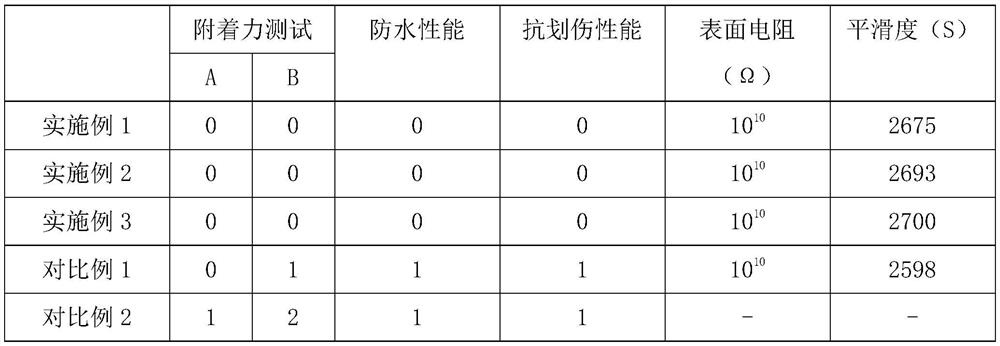

Examples

Embodiment 1

[0037]This embodiment provides a high temperature resistant thermosensitive medical film, which sequentially includes a protective layer, a thermosensitive imaging layer, a substrate layer and a back layer; wherein the protective layer includes the following raw materials in parts by weight: 55 parts of polyurethane, polyester 30 parts of vinyl alcohol, 7 parts of micron particle modification additive, 3 parts of cyclotrimethylolpropane methylal acrylate and 25 parts of deionized water.

[0038] The preparation method of the micron particle modification auxiliary agent is: take 0.5mmol of 2-aminoterephthalic acid and 0.2mmol of zirconium tetrachloride and dissolve them in 30mL of N,N-dimethylformamide respectively, and dissolve the solution After ultrasonication for 30 minutes, place in a reaction vessel, then heat at 130°C for 24 hours, and cool the resulting solution to room temperature; then centrifuge and wash 3 times with 50 mL of absolute ethanol to remove unreacted N,N-d...

Embodiment 2

[0046] This embodiment provides a high temperature resistant thermosensitive medical film, which sequentially includes a protective layer, a thermosensitive imaging layer, a substrate layer and a back layer; wherein the protective layer includes the following raw materials in parts by weight: 50 parts of polyurethane, polyester 35 parts of vinyl alcohol, 12 parts of micron particle modification additive, 5 parts of cyclotrimethylolpropane formal acrylate and 30 parts of deionized water.

[0047] The preparation method of the micron particle modification aid is: take 0.6mmol of 2-aminoterephthalic acid and 0.3mmol of zirconium tetrachloride and dissolve them in 45mL of N,N-dimethylformamide respectively, and dissolve the solution After ultrasonication for 35 minutes, place them in a reaction vessel, then heat at 120°C for 24 hours, and cool the resulting solution to room temperature; then centrifuge and wash 3 times with 80 mL of absolute ethanol to remove unreacted N,N-di Meth...

Embodiment 3

[0055] This embodiment provides a high temperature resistant thermosensitive medical film, which sequentially includes a protective layer, a thermosensitive imaging layer, a substrate layer and a back layer; wherein the protective layer includes the following raw materials in parts by weight: 60 parts of polyurethane, polyester 25 parts of vinyl alcohol, 4 parts of micron particle modification additive, 5 parts of cyclotrimethylolpropane formal acrylate and 30 parts of deionized water.

[0056] The preparation method of the micron particle modification auxiliary agent is: take 0.8mmol of 2-aminoterephthalic acid and 0.4mmol of zirconium tetrachloride and dissolve them in 50mL of N,N-dimethylformamide respectively, and dissolve the solution Sonicate for 45 minutes and place in a reaction vessel, then heat at 150°C for 24 hours, cool the resulting solution to room temperature; then centrifuge and wash with 100 mL of absolute ethanol three times to remove unreacted N,N-di Methylf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com