Equipment and method for removing hydrogen peroxide in sulfuric acid

A technology of hydrogen peroxide and sulfuric acid, applied in sulfur trioxide/sulfuric acid, chemical instruments and methods, sulfur compounds, etc., can solve the problems of destroying enzymes, loss of effective active components of catalysts, and dissolving metals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The invention provides a device and a method for removing hydrogen peroxide in sulfuric acid.

[0047] In order to enable those skilled in the art to have a further understanding and understanding of the purpose, features and effects of the present invention, the detailed description of the embodiments and drawings is as follows:

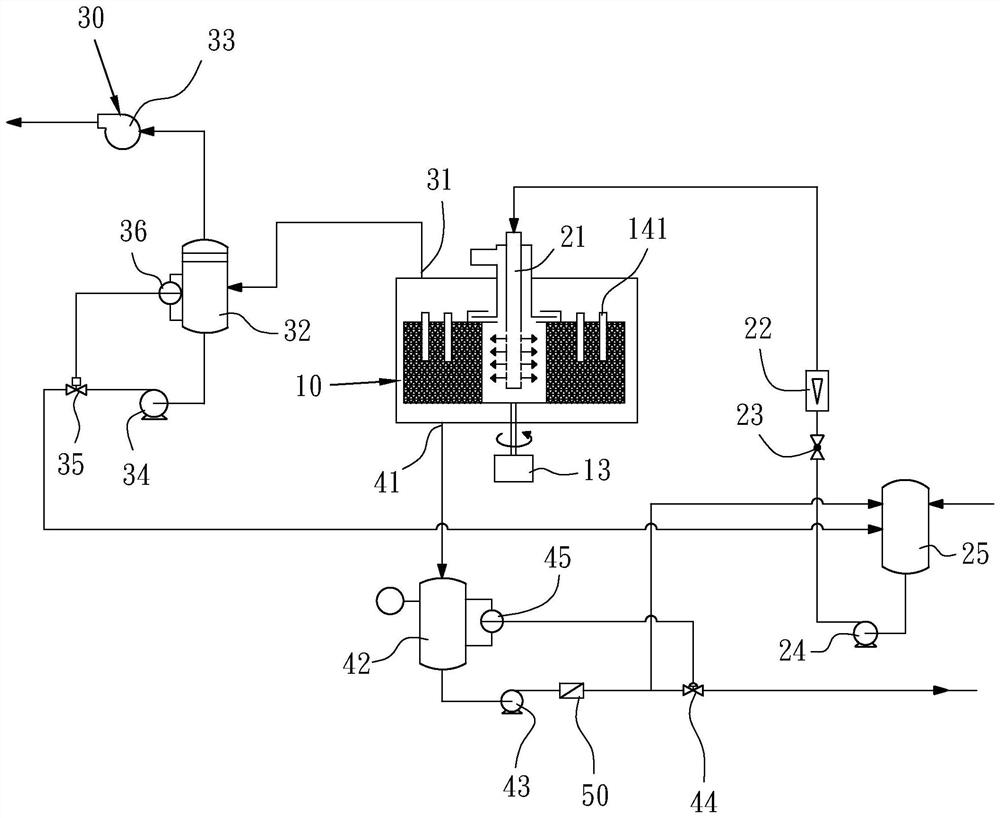

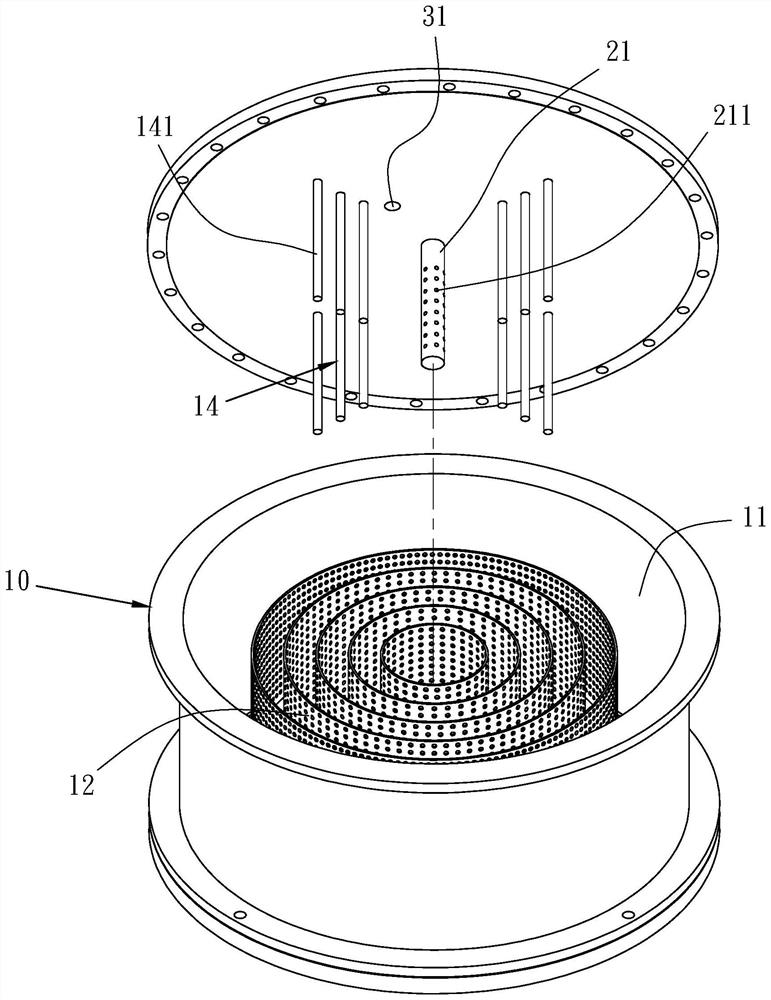

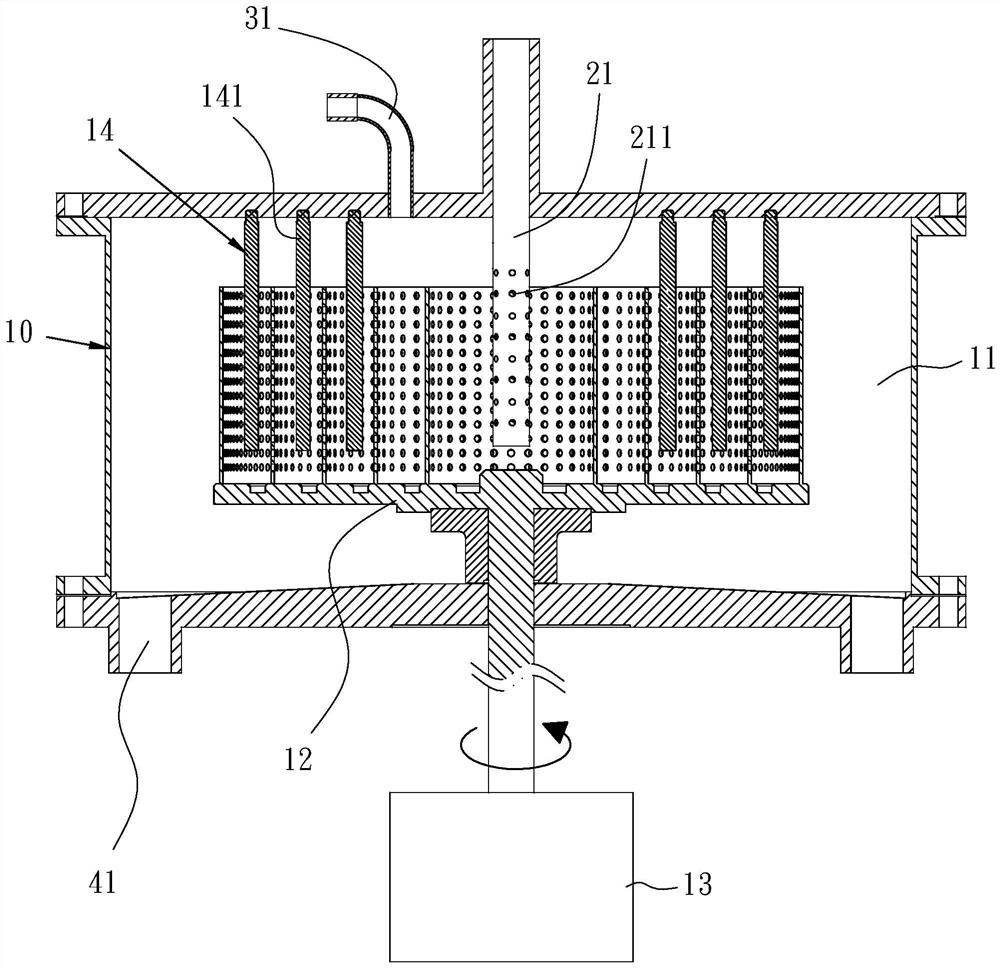

[0048] refer to Figure 1-3 As shown, the present invention provides a kind of equipment for removing hydrogen peroxide in sulfuric acid, comprising:

[0049] A supergravity device 10 is provided with a closed processing space 11, and a rotor device 12 is arranged from bottom to top in the closed processing space 11, and the rotor device 12 is connected to a power source 13 to rotate at a high speed above 200rpm. The rotor device 12 is set as a number of inner sieve plates, and the inner sieve plates are provided with a plurality of inner sieve plate holes, and the aperture is below 5mm. The closed processing space 11 is provided with severa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com