Synthesis method and application of heavy metal stabilizing agent

A technology of stabilizer and synthesis method, applied in chemical instruments and methods, applications, organic chemistry, etc., can solve the problems of high toxicity, expensive raw materials, cumbersome process, etc., and achieve performance reproducibility, abundant sources, and synthetic process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

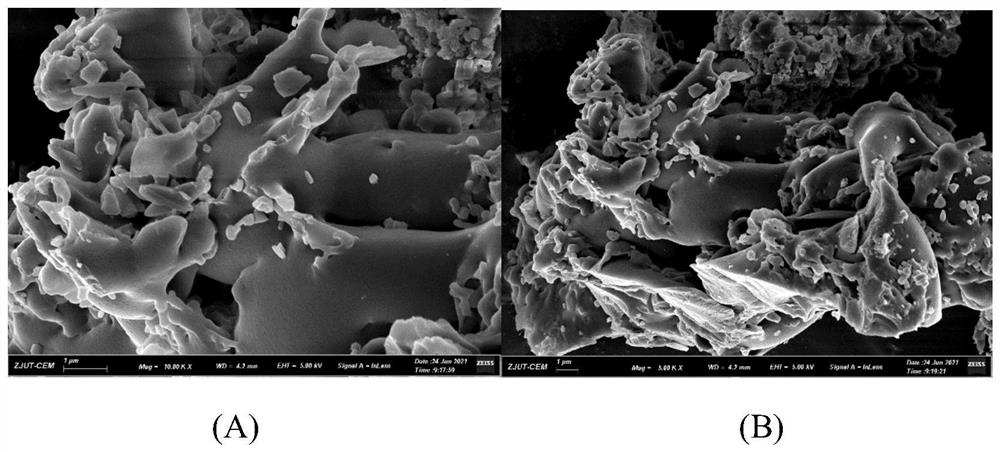

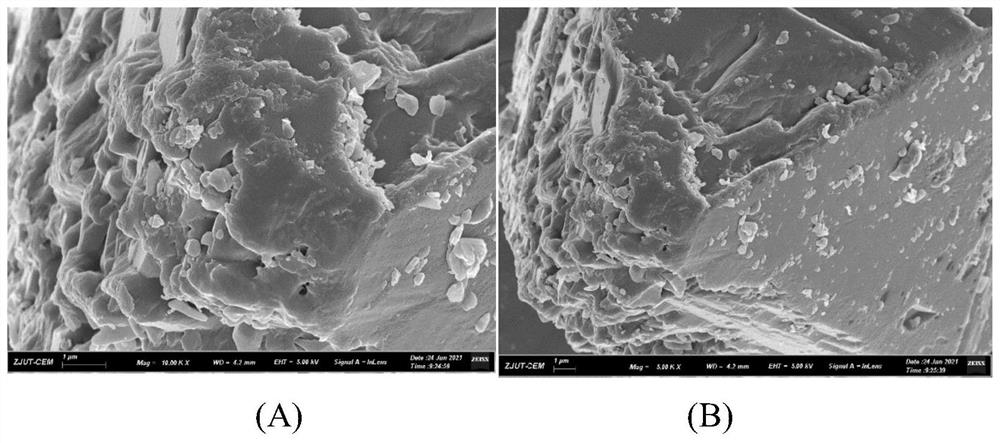

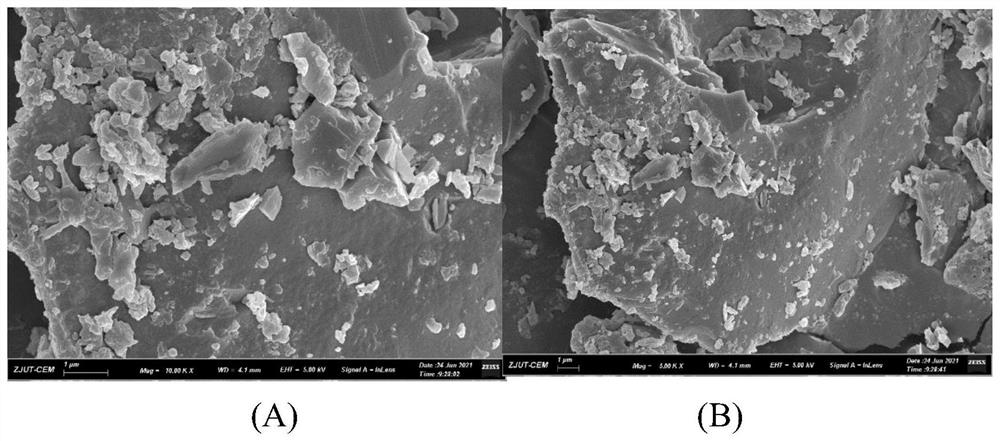

Image

Examples

Embodiment 1

[0032] Under the oil bath, 10.00 g of cashew phenol was added to a three-mouth flask equipped with a stirrer, a spherical condenser and a thermometer, and the temperature was heated to 40 ° C. After sufficiently melting of cashews, 1.05 g of sodium hydroxide was added, and the constant temperature was stirred for 30 min. A 7 g of a mass fraction of 37% formaldehyde aqueous solution and 50 ml DMF solution were added, and the temperature was tapered to 60 ° C, and the constant temperature was stirred for 70 min, then 2.85 g of mass fraction of 37% formaldehyde aqueous solution. 9.11 g of melamine was added, warmed to 80 ° C, and the constant temperature was stirred for 30 min, followed by cooling to 30 ° C. 4.50 g of thiourea was added in batches, warmed to 90 ° C, and the constant temperature was stirred for 9 h. After cooling, filtration was carried out, washed with acetone and deionized water, and the resulting white solid was dried in an oven at 70 ° C.

[0033] The white solid ...

Embodiment 2

[0035] Under oil bath conditions, 12.00 g of cashews were added to a three-mouth flask equipped with a stirrer, a spherical condensate and a thermometer, and the temperature was heated to 70 ° C. After sufficiently melting of cashews, 1.89 g of sodium hydroxide was added, and the constant temperature was stirred for 15 min. The 9.5 g of a mass fraction of 37% of the formaldehyde solution and 60 ml DMF solution were added, and the temperature was raised to 90 ° C, and the constant temperature was stirred for 30 min, then 4.24 g of mass fraction was 37% formaldehyde solution. 13.92 g of melamine was added, warmed to 110 ° C, and the constant temperature was stirred for 45 min, followed by cooling to 70 ° C. 6.60 g of thiourea was added batch, warmed to 125 ° C, and the constant temperature was stirred for 12 h. After cooling, filtration was carried out, washed with acetone and deionized water, and the obtained white solid was placed in an oven at an oven at 80 ° C.

[0036] The whit...

Embodiment 3

[0038] Under oil bath conditions, 10.00 g of cashew phenol was added to a three-mouth flask equipped with a stirrer, a spherical condensate and a thermometer, and heated to 60 ° C. After sufficiently melting of cashews, 1.05 g of sodium hydroxide was added, and the constant temperature was stirred for 20 min. The 7 g of the mass fraction of 37% of the formaldehyde solution and 60 ml DMF solution were added, and the temperature was raised to 90 ° C, and the constant temperature was stirred for 50 min, then 2.85 g of mass fraction of 37% formaldehyde solution was added. 9.11 g of melamine was added, warmed to 100 ° C, and the constant temperature was stirred for 40 min, followed by cooling to 45 ° C. 4.50 g of thiourea was added batch, warmed to 110 ° C, and the constant temperature was stirred for 14 h. After cooling, filtration was carried out, washed with acetone and deionized water, and the resulting white solid was dried in an oven at 100 ° C.

[0039] The white solid product w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com