A kind of extraction process of ginkgolide

A technique for extracting ginkgolides, which is applied in the field of extraction techniques for ginkgolides, can solve the problems of increasing the production process, not being suitable for large-scale production, and unsafe organic solvents, etc., achieving significant economic benefits, reducing losses, and reducing The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

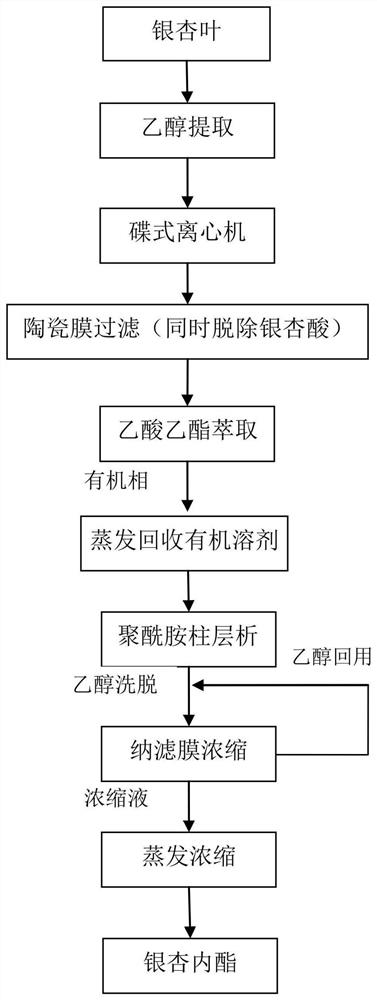

[0066] Embodiment 1: according to such as figure 2 The flow chart for the extraction of ginkgolides is shown:

[0067] (1) Ginkgo biloba is crushed to 20 meshes, leached with 60% ethanol solution at 50-80° C., and extracted 6 times to obtain the crude extract of ginkgo biloba;

[0068] (2) The crude extract obtained in step (1) is evaporated and concentrated, and after being concentrated 6 times, the Ginkgo biloba extract concentrate is obtained, and ethanol is recovered simultaneously;

[0069] (3) centrifuging the ginkgo leaf extract concentrate obtained in step (2) at 6000rpm / min disc centrifuge for 10min to obtain the ginkgo extract centrifugate, the content of ginkgolide is 0.15%, and the impurity content is 5.3%;

[0070] (4) After the ginkgo extract centrifugate obtained by step (3) is filtered and clarified through the ceramic ultrafiltration membrane after activation and modification, after impurity removal, the ceramic membrane filtrate is obtained, the content of ...

Embodiment 2

[0083] Embodiment 2: according to as figure 2 The flow chart for the extraction of ginkgolides is shown:

[0084] (1) Ginkgo biloba is crushed to 5 meshes, extracted with 60% ethanol solution at 50-80° C., and extracted 6 times to obtain the crude extract of ginkgo biloba;

[0085] (2) The crude extract obtained in step (1) is evaporated and concentrated, and after being concentrated 6 times, the Ginkgo biloba extract concentrate is obtained, and ethanol is recovered simultaneously;

[0086] (3) the ginkgo leaf extract concentrate that step (2) is obtained is centrifuged through a 6000rpm / min disc centrifuge for 10min to obtain the ginkgo extract centrifugate, the content of ginkgolide is 0.15%, and the impurity content is 5.5%;

[0087] (4) obtaining the ceramic membrane filtrate after the ginkgo extract centrifugate obtained in step (3) is filtered and clarified by activated modified ceramic ultrafiltration membrane, and impurities are removed, the content of ginkgolide is...

Embodiment 3

[0100] Embodiment 3: according to such as figure 2 The flow chart for the extraction of ginkgolides is shown:

[0101] (1) Ginkgo biloba is crushed to 40 meshes, extracted with 60% ethanol solution at 50-80° C., and extracted 6 times to obtain the crude extract of Ginkgo biloba;

[0102] (2) The crude extract obtained in step (1) is evaporated and concentrated, and after being concentrated 6 times, the Ginkgo biloba extract concentrate is obtained, and ethanol is recovered simultaneously;

[0103] (3) the ginkgo leaf extract concentrated solution that step (2) is obtained is centrifuged 10min through 8000rpm / min disc centrifuge, obtains ginkgo extract centrifugate, the content of ginkgolide is 0.16%, and impurity content is 5.6%;

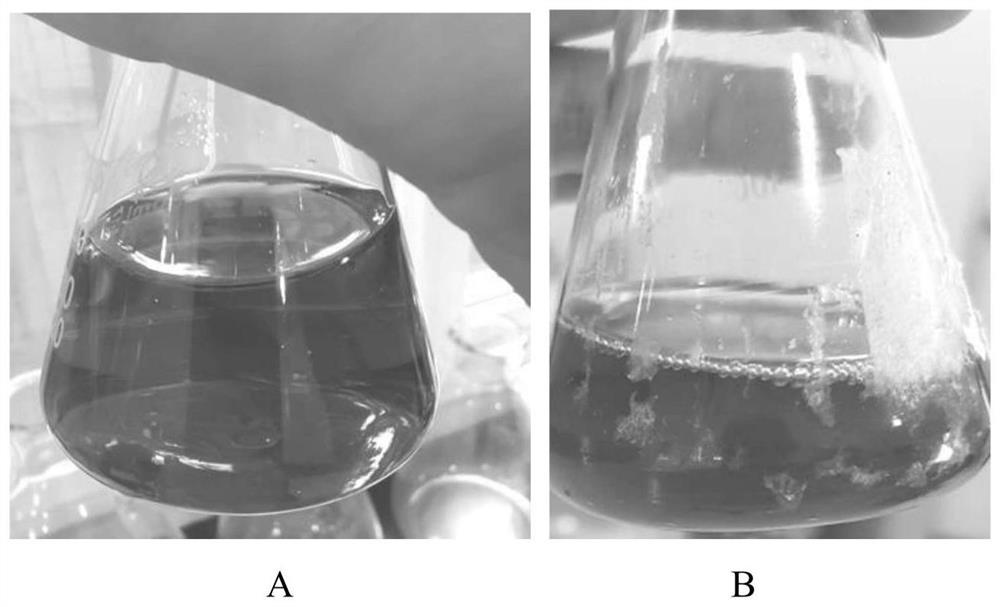

[0104] (4) after the ginkgo extract centrifugate obtained by step (3) is filtered and clarified through the ceramic ultrafiltration membrane after the activation modification, after impurity removal, obtain such as image 3 In the shown ceramic m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com