Preparation method of color-adjustable fluorescent MOF-dye composite material

A MOF-, composite material technology, applied in luminescent materials, chemical instruments and methods, sustainable architecture, etc., can solve problems such as poor fluorescence regulation performance, overcome fluorescence quenching, improve composite efficiency, and achieve color tunability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A method for preparing a color-adjustable fluorescent MOF-dye composite material of the present invention is specifically implemented according to the following steps:

[0046] Step 1, preparing fluorescent MOF material;

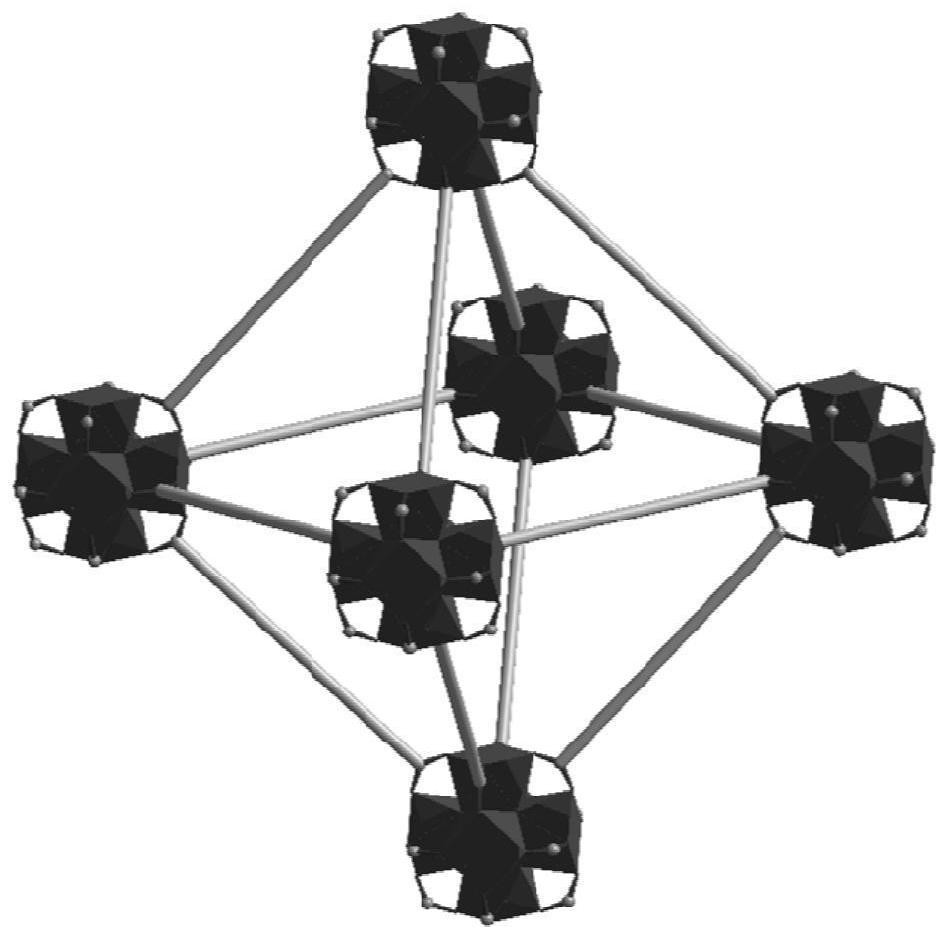

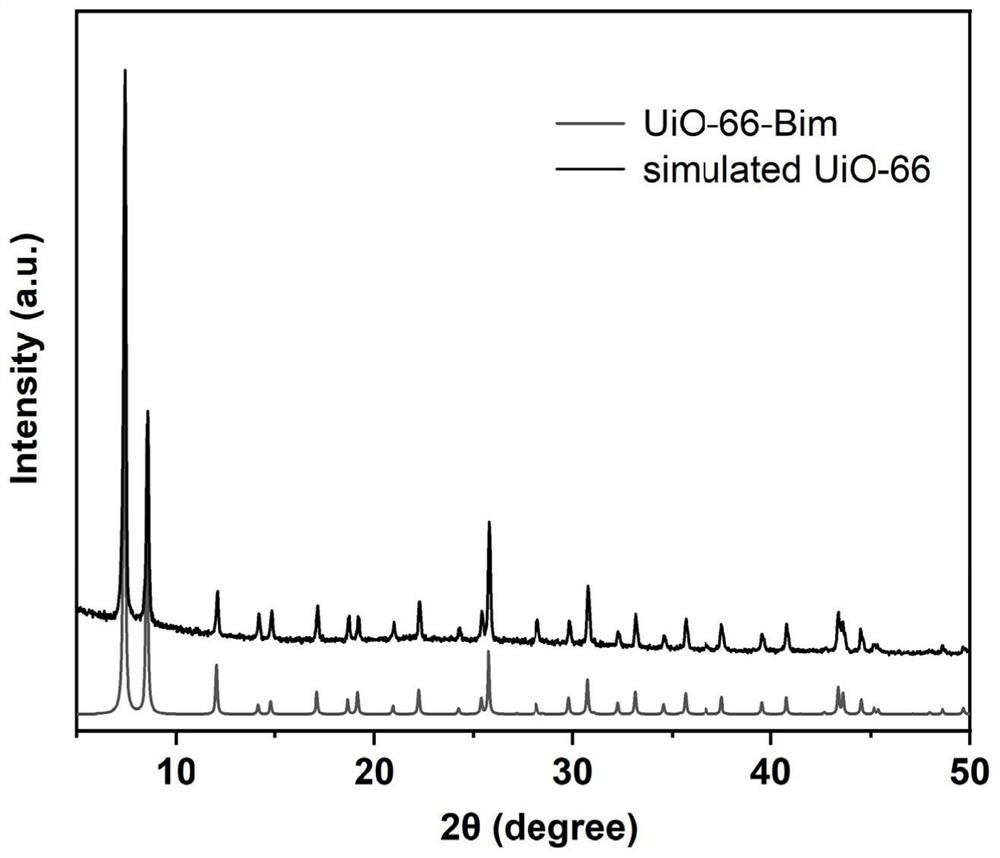

[0047]Weigh 23.3 mg (0.1 mmol) of zirconium tetrachloride and 28.2 mg (0.1 mmol) of Bim-H 2 BDC (2-(benzo[d]imidazol-1-yl)terephthalic acid) was placed in a 10 mL vial, and 5 mL of N,N-dimethylformamide and 0.5 mL of glacial acetic acid were added to obtain a mixed solution. React the above mixed solution in an oven at 120°C for 72 hours at a constant temperature, transfer the reacted solution to a centrifuge tube, centrifuge at 7000r / min for 7 minutes, absorb the supernatant, add DMF and continue centrifuging once, repeat the above operation Afterwards, they were centrifuged and washed three times with methanol. The centrifuged sample was dried in a vacuum oven at 60°C for 12 hours to obtain a light pink solid powder material;

[0048] Its specifi...

Embodiment 2

[0053] A method for preparing a color-adjustable fluorescent MOF-dye composite material of the present invention is specifically implemented according to the following steps:

[0054] Step 1, preparing fluorescent MOF material;

[0055] Specifically: zirconium salt, acetic acid, Bim-H 2 BDC is mixed with a solvent for solvothermal reaction, and then the reacted solution is washed twice with DMF, then washed with methanol three times, and dried in vacuum to obtain a fluorescent MOF material;

[0056] Bim-H 2 BDC is 2-(benzo[d]imidazol-1-yl)terephthalic acid; the zirconium salt is zirconium tetrachloride; the solvent is N,N-dimethylformamide;

[0057] Zirconium salt, Bim-H 2 The molar ratio of BDC, acetic acid and solvent is 3:1:0.5:5;

[0058] The temperature of the solvothermal reaction is 120°C, and the time is 24h;

[0059] The drying temperature is 60°C, and the drying time is 36 hours;

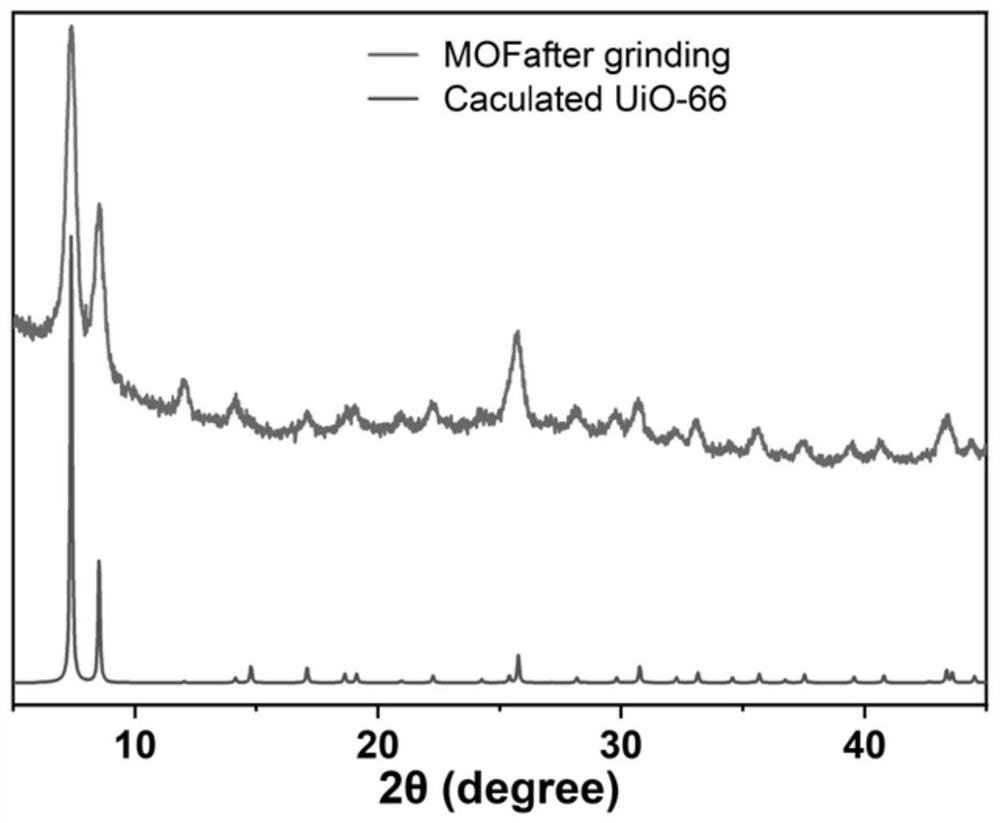

[0060] Step 2: Grind the fluorescent MOF material and rhodamine 6G in a mortar f...

Embodiment 3

[0064] A method for preparing a color-adjustable fluorescent MOF-dye composite material of the present invention is specifically implemented according to the following steps:

[0065] Step 1, preparing fluorescent MOF material;

[0066] Specifically: zirconium salt, acetic acid, Bim-H 2 BDC is mixed with a solvent for solvothermal reaction, and then the reacted solution is centrifugally washed twice with DMF, then three times with methanol, and vacuum-dried to obtain a fluorescent MOF material, whose chemical formula is {[Zr 6 o 4 (OH) 4 ](Bim-BDC) 6} n ;

[0067] Bim-H 2 BDC is 2-(benzo[d]imidazol-1-yl)terephthalic acid; the zirconium salt is zirconium tetrachloride; the solvent is N,N-dimethylformamide;

[0068] Zirconium salt, Bim-H 2 The molar ratio of BDC, acetic acid and solvent is 2:1:0.5:5;

[0069] The temperature of the solvothermal reaction is 100°C, and the time is 40h;

[0070] The drying temperature is 65°C, and the drying time is 28 hours;

[0071] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com