Preparation method of large-size two-dimensional bismuth iodide single crystal

A bismuth iodide and large-size technology, which is applied in the field of preparation of large-size two-dimensional bismuth iodide single crystals, can solve problems such as inability to carry out further applications, and achieve the effects of convenient operation, good repeatability, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing a large-size two-dimensional bismuth iodide single crystal according to Example 1 of the present invention comprises the following steps:

[0025] S1, placing bismuth iodide powder in a corundum boat with an opening at one end, and then buckling the fluorophlogopite substrate on the corundum boat to form a gas phase trap; 1 g of bismuth iodide powder was added.

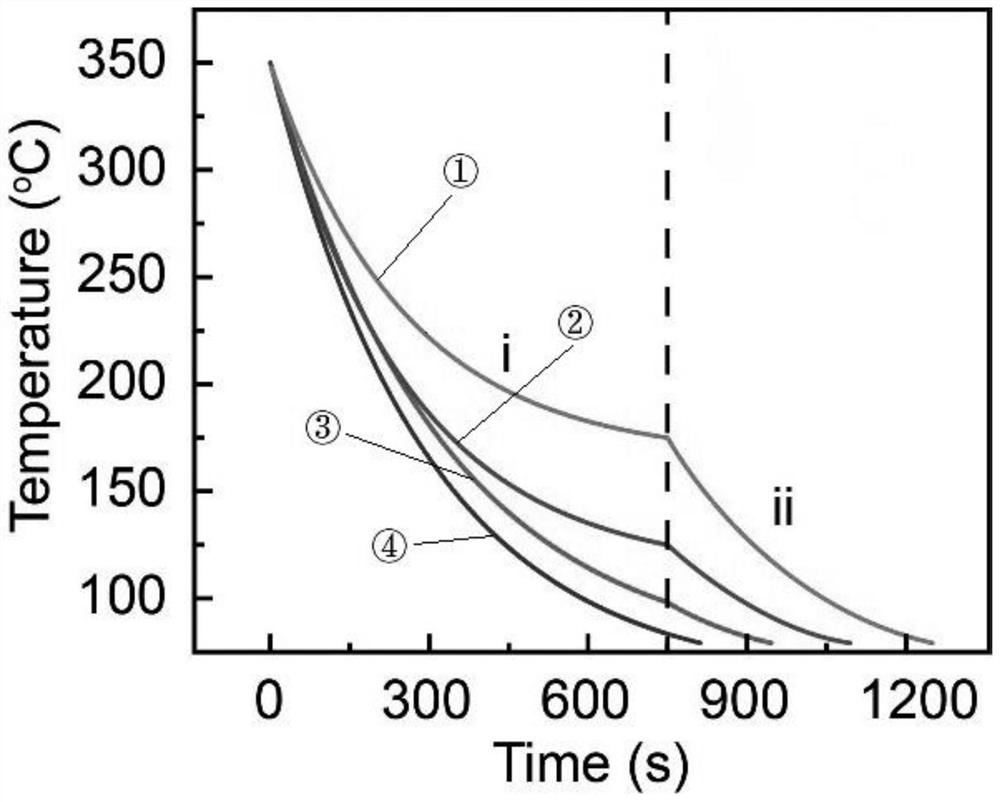

[0026] S2, put the gas phase trap into the central position of the tube furnace, and heat it to make the bismuth iodide powder reach the volatilization temperature; specifically, the opening direction of the corundum boat is consistent with the flow direction of the incoming argon and hydrogen gas Inversely, the volatilization temperature is 380°C.

[0027] S3, feeding argon and hydrogen into the tube furnace, diluting the gasified bismuth iodide and performing a reduction reaction under a constant temperature environment; feeding argon as a dilution gas, and feeding hydrogen as a reducin...

Embodiment 2

[0031] A method for preparing a large-size two-dimensional bismuth iodide single crystal according to Example 2 of the present invention comprises the following steps:

[0032] S1, placing bismuth iodide powder in a corundum boat with an opening at one end, and then buckling the fluorophlogopite substrate on the corundum boat to form a gas phase trap; wherein, 0.5 g of bismuth iodide powder was added.

[0033] S2, put the gas phase trap into the central position of the tube furnace, and heat it to make the bismuth iodide powder reach the volatilization temperature; specifically, the opening direction of the corundum boat is consistent with the flow direction of the incoming argon and hydrogen gas Inversely, the volatilization temperature is 330°C.

[0034] S3, feeding argon and hydrogen into the tube furnace, diluting the gasified bismuth iodide and performing a reduction reaction under a constant temperature environment; feeding argon as a dilution gas, and feeding hydrogen a...

Embodiment 3

[0038] A method for preparing a large-size two-dimensional bismuth iodide single crystal according to Example 3 of the present invention comprises the following steps:

[0039] S1, placing bismuth iodide powder in a corundum boat with an opening at one end, and then placing the fluorophlogopite substrate upside down on the corundum boat to form a gas phase trap; wherein, 0.1 g of bismuth iodide powder was added.

[0040] S2, put the gas phase trap into the central position of the tube furnace, and heat it to make the bismuth iodide powder reach the volatilization temperature; specifically, the opening direction of the corundum boat is consistent with the flow direction of the incoming argon and hydrogen gas Inversely, the volatilization temperature is 280°C.

[0041] S3, feeding argon and hydrogen into the tube furnace, diluting the gasified bismuth iodide and performing a reduction reaction under a constant temperature environment; feeding argon as a dilution gas, and feeding h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com